Preparation method of microbial pre-fermentation coating multilayer microcapsule

A microbial fermentation and microcapsule technology, applied in the field of microbial technology and biology, can solve problems such as inappropriate microbial packaging, and achieve the effects of convenient reuse, reduced production cost, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

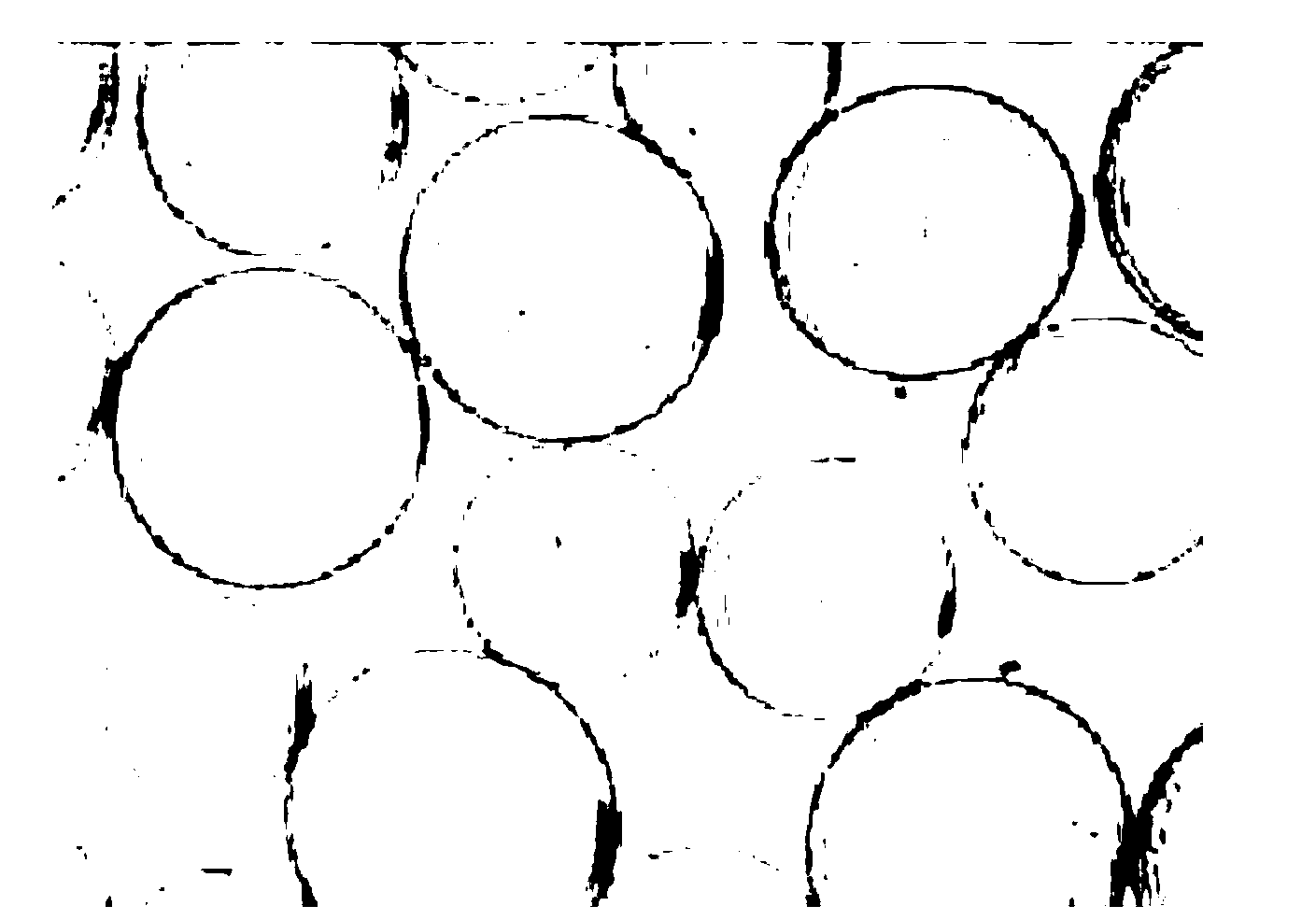

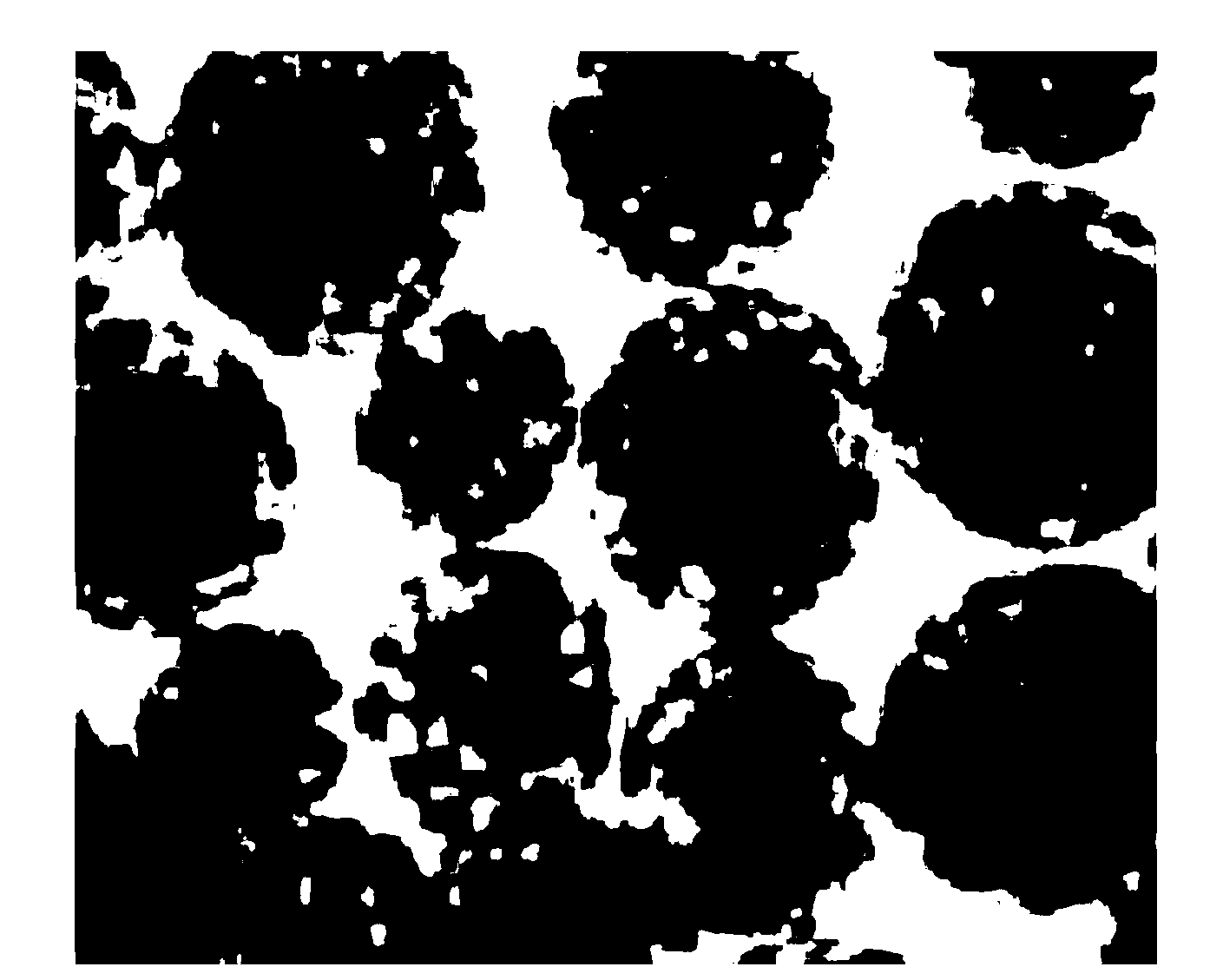

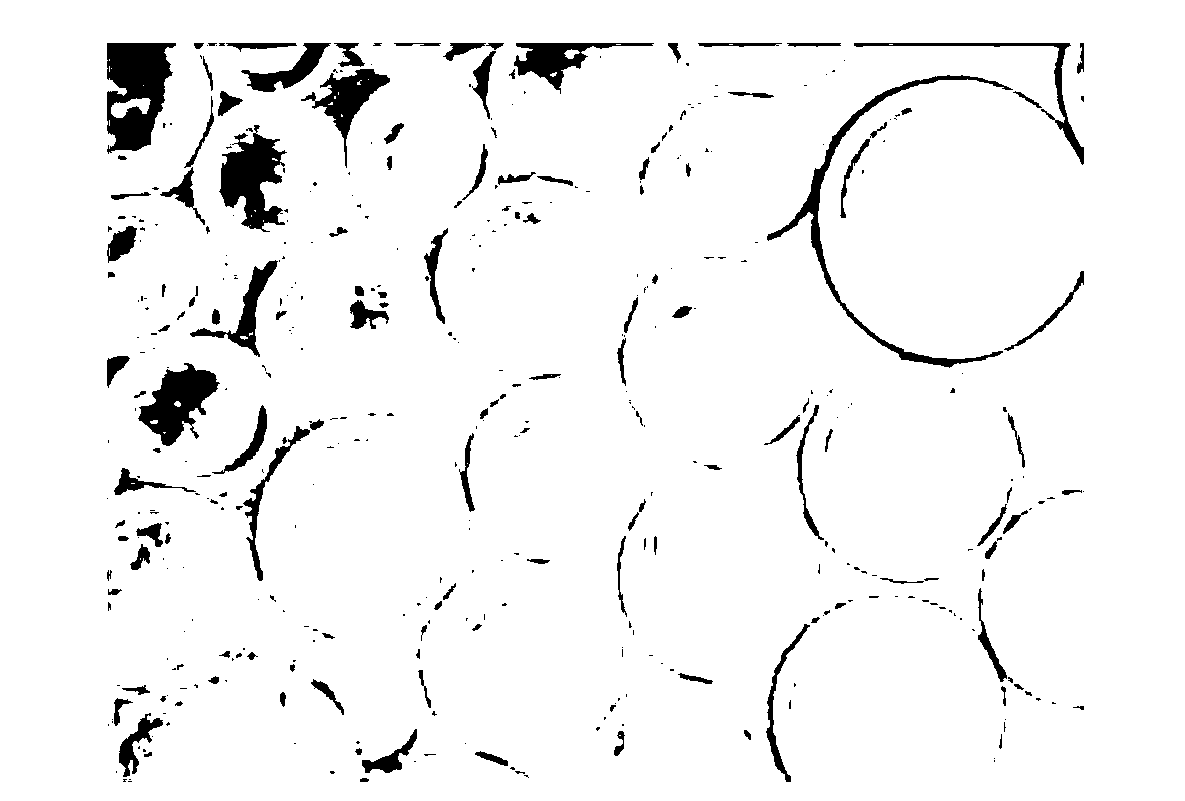

Image

Examples

Embodiment 1

[0055] The yeast double-layer microcapsules described in this example are prepared through the following steps:

[0056] (1) Preparation of single-layer microcapsules: Under sterile conditions, take aseptically treated sodium alginate solution with a concentration of 1 g / L, add yeast seed solution in logarithmic growth phase to be coated, mix well, to 10 6 The density is about cfu / ml; and the mixed solution obtained above is filtered with a sterile filter membrane with a diameter of less than 0.22 μm, and the flow rate is 4m 3 / h of high-pressure air is extruded and sprayed into the aseptically treated calcium chloride solution with a concentration of 0.1mol / L through a hollow circular drop-shaped nozzle, stirred at a slow speed and solidified for 20 minutes, and the supernatant is filtered to obtain the required single-layer microcapsules, and washed with sterile water;

[0057] (2) Preparation of double-layer microcapsules: adding the single-layer microcapsules obtained in...

Embodiment 2

[0061] The yeast double-layer microcapsules described in this example are prepared through the following steps:

[0062] (1) Preparation of single-layer microcapsules: Under aseptic conditions, take aseptically treated sodium alginate solution with a concentration of 3 g / L, add the yeast seed solution to be coated, and mix evenly until 10 6 The density is about cfu / ml; and the mixed solution obtained above is filtered with a sterile filter membrane with a diameter of less than 0.22 μm, and the flow rate is 6m 3 / h of high-pressure air is sprayed into the aseptically treated calcium chloride solution with a concentration of 0.3mol / L through a hollow circular drop-shaped nozzle, stirred at a slow speed and solidified for 20 minutes, and the supernatant is filtered to obtain the required single Layer microcapsules, and wash with sterile water;

[0063] (2) Preparation of double-layer microcapsules: Add the single-layer microcapsules obtained in step (1) into an acidic buffer of ...

Embodiment 3

[0067] The yeast double-layer microcapsules described in this example are prepared through the following steps:

[0068] (1) Preparation of single-layer microcapsules: under aseptic conditions, take aseptically treated sodium alginate solution with a concentration of 1 g / L, add yeast seed liquid to be coated, and mix evenly; The mixed solution is filtered with a sterile filter membrane with a diameter of less than 0.22 μm and a flow rate of 4 m 3 / h of high-pressure air is sprayed into the aseptically treated calcium chloride solution with a concentration of 0.1mol / L through a hollow circular drop-shaped nozzle, stirred evenly and solidified, and the supernatant is filtered to obtain the required single-layer microcapsules , and washed with sterile water;

[0069] (2) Preparation of double-layer microcapsules: adding the single-layer microcapsules obtained in step (1) into an acidic buffer solution of chitosan with an initial concentration of 3g / L for film-forming reaction, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com