Method for enabling cable to be termite-proof and termite-proof cable

A termite and cable technology, which is applied in the direction of insulating cables, cable/conductor manufacturing, cables, etc., can solve the problems of short protection time, limited protection, secondary pollution, etc., and achieve the effect of improving termite resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of termite-resistant cables

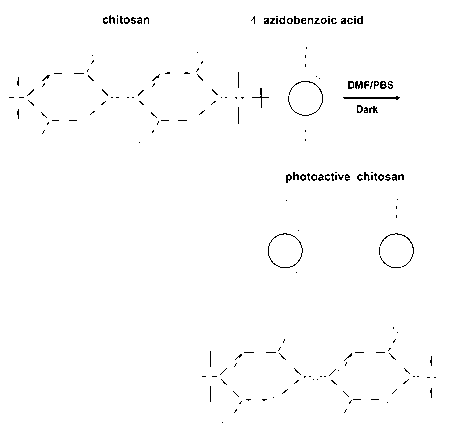

[0036] (1) Preparation of photoactive chitosan, the synthesis principle is as follows figure 1 shown, including the following steps:

[0037] S01. PBS solution with pH6.5 and glacial acetic acid are made into the acetic acid solution that volume fraction is 15%, add chitosan, prepare 3% by weight chitosan solution;

[0038] S02. Add 16.8mg of N-(4-azidobenzoyl) succinimide and 8ml of 3% by weight chitosan solution into the mixed solution whose volume ratio of DMF / PBS is 4:1, so that the total volume of the solution is 20ml ;

[0039] S03. Stirring and reacting the solution obtained in S02. in the dark for 48 hours to obtain photoactive chitosan.

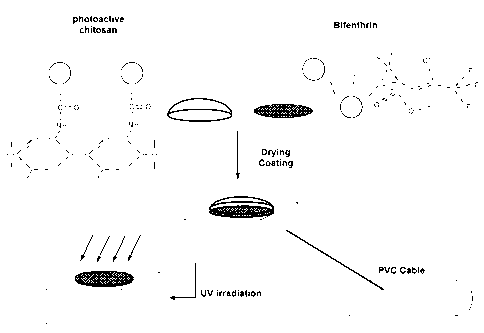

[0040] (2) Preparation of termite-resistant cables, such as figure 2 shown, including the following steps:

[0041] S01. First drop the termite medicine onto the surface of the cable sheath, then add the above-mentioned photoactive chitosan, mix well under dark conditio...

Embodiment 2

[0043] Embodiment 2 Synthetic effect analysis of photoactive chitosan

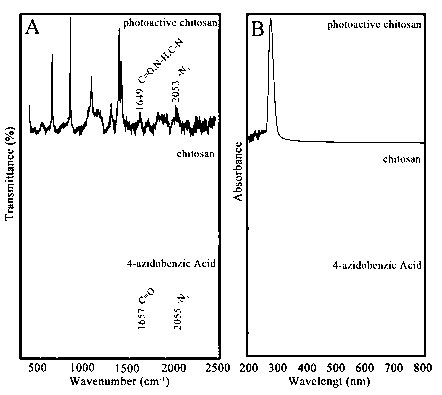

[0044] Such as image 3 As shown in A, in the Raman spectrum, the stretching peak of N-(4-azidobenzoyl) succinimide azido group is at 2055, and the photoactive chitosan is at 2053 cm after synthesis. -1 This peak also appeared, indicating that the photoactive chitosan after synthesis has also taken an azide group; N-(4-azidobenzoic acid group) succinimide is -1 It is a carbonyl group, and after synthesis, the photoactive chitosan is at 1649cm -1 The amide I band appears, and the characteristic peak of carbonyl group is obvious, but chitosan itself has no carbonyl group. The analysis is that the amino group on chitosan and the carboxyl group of 4-azidobenzoic acid synthesize an amide group, showing the stretching activity of carbonyl group, indicating that Photoactive chitosan was synthesized. from image 3The ultraviolet spectrum of B can be seen that the ultraviolet absorption peak of N-(4-azidobenzoy...

Embodiment 3

[0045] Example 3 Analysis of the cable surface grafted with photoactive chitosan and embedded with termite medicine

[0046] (1) Scanning electron microscope

[0047] Such as Figure 4 It can be seen from a that the surface structure of the cable sheath is uneven, and the photoactive chitosan ( Figure 4 After , b), the layered irregular structure appears on the surface of the material and internal voids can be observed, and a three-dimensional structure of cross-linking and branching is formed on the surface, and the drug is embedded ( Figure 4 , c), the surface presents an irregular package shape, and a cross-linked spatial structure also appears, indicating that the drug has been cross-linked and grafted on the cable sheath; Figure d has a flat surface, grafted with photoactive chitosan ( Figure 4 , e) After, the surface is rough and small particles appear, embedding the drug ( Figure 4 , f) After that, a large bag-like structure appeared, and it was in an embedded st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com