A modifier for inorganic modified fast-growing materials prepared in a high-temperature and low-oxygen environment

A technology of inorganic modification, high temperature and low oxygen, which is applied in the direction of wood impregnation, impregnation of wood, and manufacturing tools, etc., can solve the problems of restricting the development of fast-growing wood inorganic modification technology, secondary pollution of chemical substances, and insufficient size of test pieces. Achieve the effects of improving termite resistance, improving mechanical strength, preventing the generation and extension of defects and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

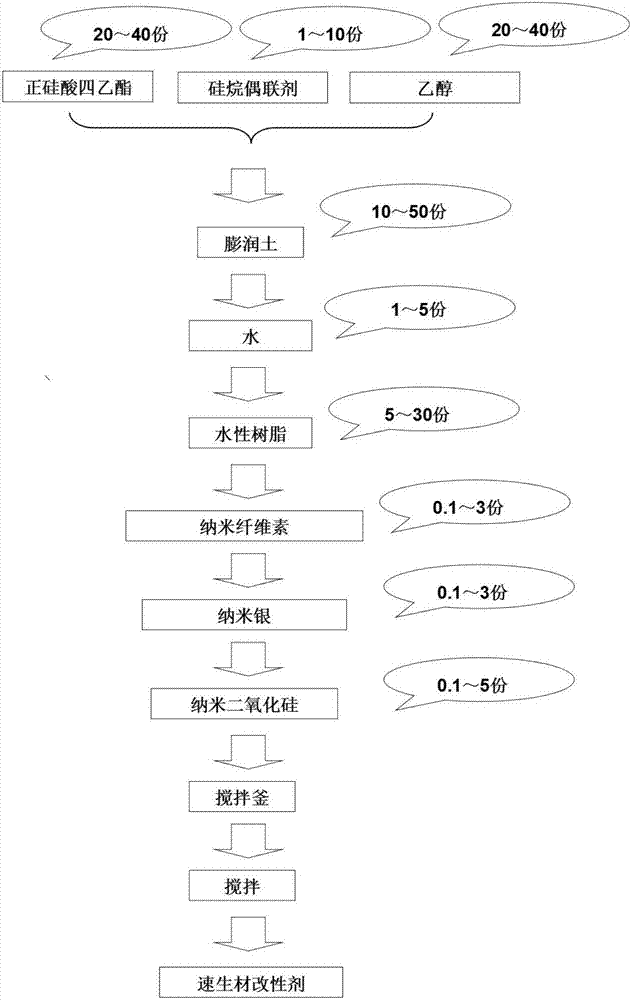

[0037] Such as figure 1 Shown, a kind of high-temperature low-oxygen environment preparation is used for the preparation method of inorganic modified fast-growing material modifier, comprises the following steps:

[0038] (1) Mix tetraethyl orthosilicate, ethanol, and silane coupling agent, wherein the tetraethyl orthosilicate is controlled at 15 to 40 parts by weight, and the ethanol is controlled at 10 to 30 parts by weight, and the silane coupling agent is The parts by weight of the joint agent are controlled at 15-40 parts;

[0039] (2), adding bentonite, water, water-based resin, nano-cellulose, nano-silver, and nano-silicon dioxide to the above system in sequence, wherein the parts by weight of bentonite are controlled at 10-50 parts, and the parts by weight of water are controlled at 1-5 parts The parts by weight of water-based resin are controlled at 5-30 parts, the parts by weight of nano-cellulose are controlled at 0.1-3 parts, the parts by weight of nano-silver are...

Embodiment 1

[0045]A method for preparing a modifier for inorganic modified fast-growing materials in a high-temperature and low-oxygen environment, comprising the following steps:

[0046] (1), 20kg tetraethyl orthosilicate, 20kg ethanol, 4kg silane coupling agent are mixed.

[0047] (2) Add 35kg of bentonite, 3kg of water, 13kg of water-based resin, 3kg of nanocellulose, 1kg of nanosilver, and 1kg of nanosilica to the above system in sequence.

[0048] (3), stirring for 30 minutes;

[0049] (4), after the reaction is finished, the obtained product is the modifier that can be used for inorganic modified fast-growing materials prepared in the high-temperature and low-oxygen environment.

Embodiment 2

[0051] A method for preparing a modifier for inorganic modified fast-growing materials in a high-temperature and low-oxygen environment, comprising the following steps:

[0052] (1), 40kg tetraethyl orthosilicate, 20kg ethanol, 5kg silane coupling agent are mixed.

[0053] (2) Add 20kg of bentonite, 1.5kg of water, 10kg of water-based resin, 1.5kg of nanocellulose, 1kg of nanosilver, and 1kg of nanosilica to the above system in sequence.

[0054] (3), stirring for 30 minutes;

[0055] (4), after the reaction is finished, the obtained product is the modifier that can be used for inorganic modified fast-growing materials prepared in the high-temperature and low-oxygen environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com