Coated cogwheel

A coating and gear technology, applied in coating, belt/chain/gear, metal material coating process, etc., can solve the problems of limiting gear life, coating peeling, etc., and achieve the effect of avoiding peeling and good performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

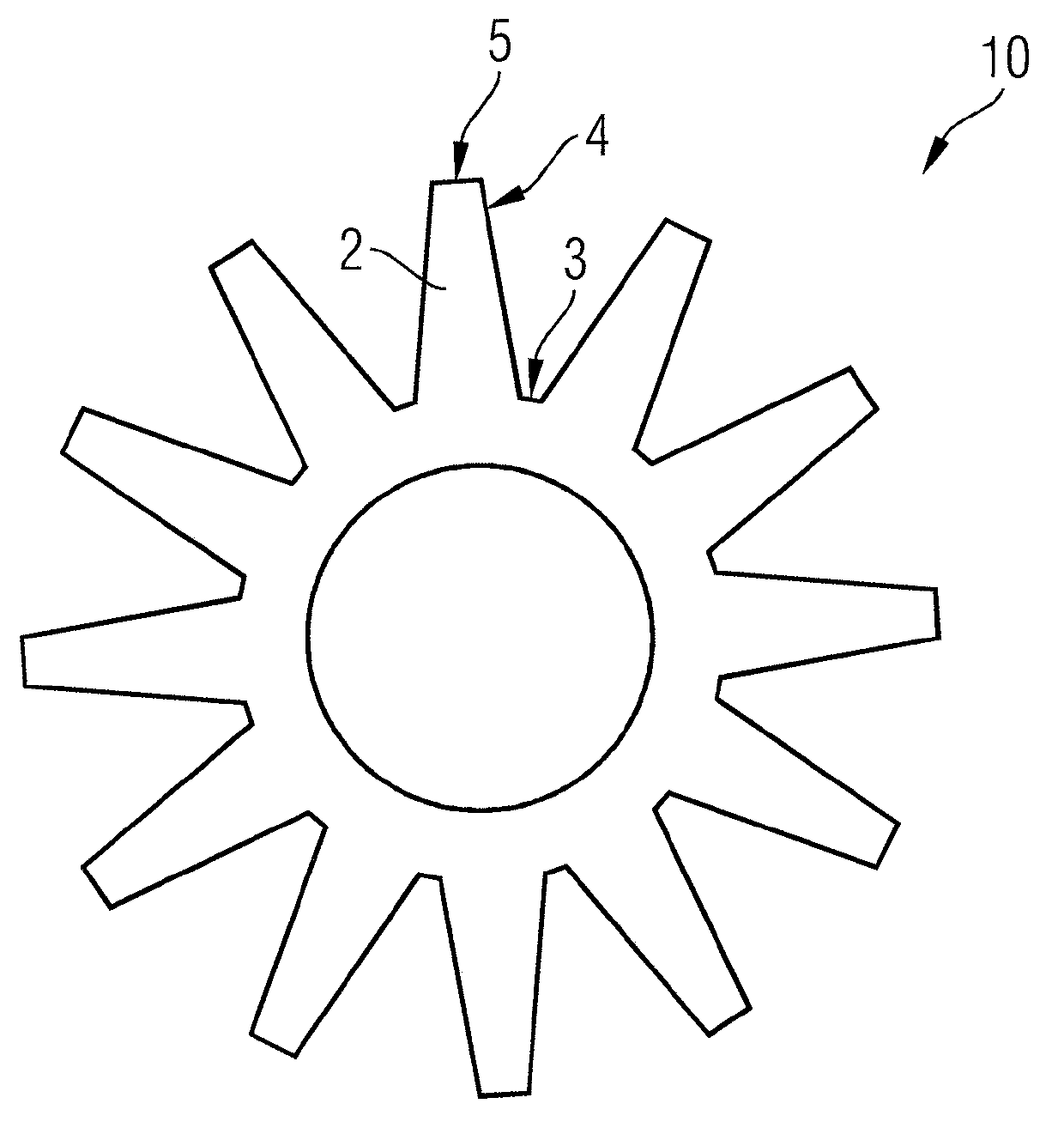

[0028] figure 1 A view is shown of a gear body 10 to be coated, which consists of a base material, for example hardened steel such as 16MnCr5 or 18CrNiMo7-6. Gear teeth 2 are arranged along the outer periphery of the gear body 10 , and the gear teeth respectively have a dedendum 3 , a tooth surface 4 and a tooth top 5 .

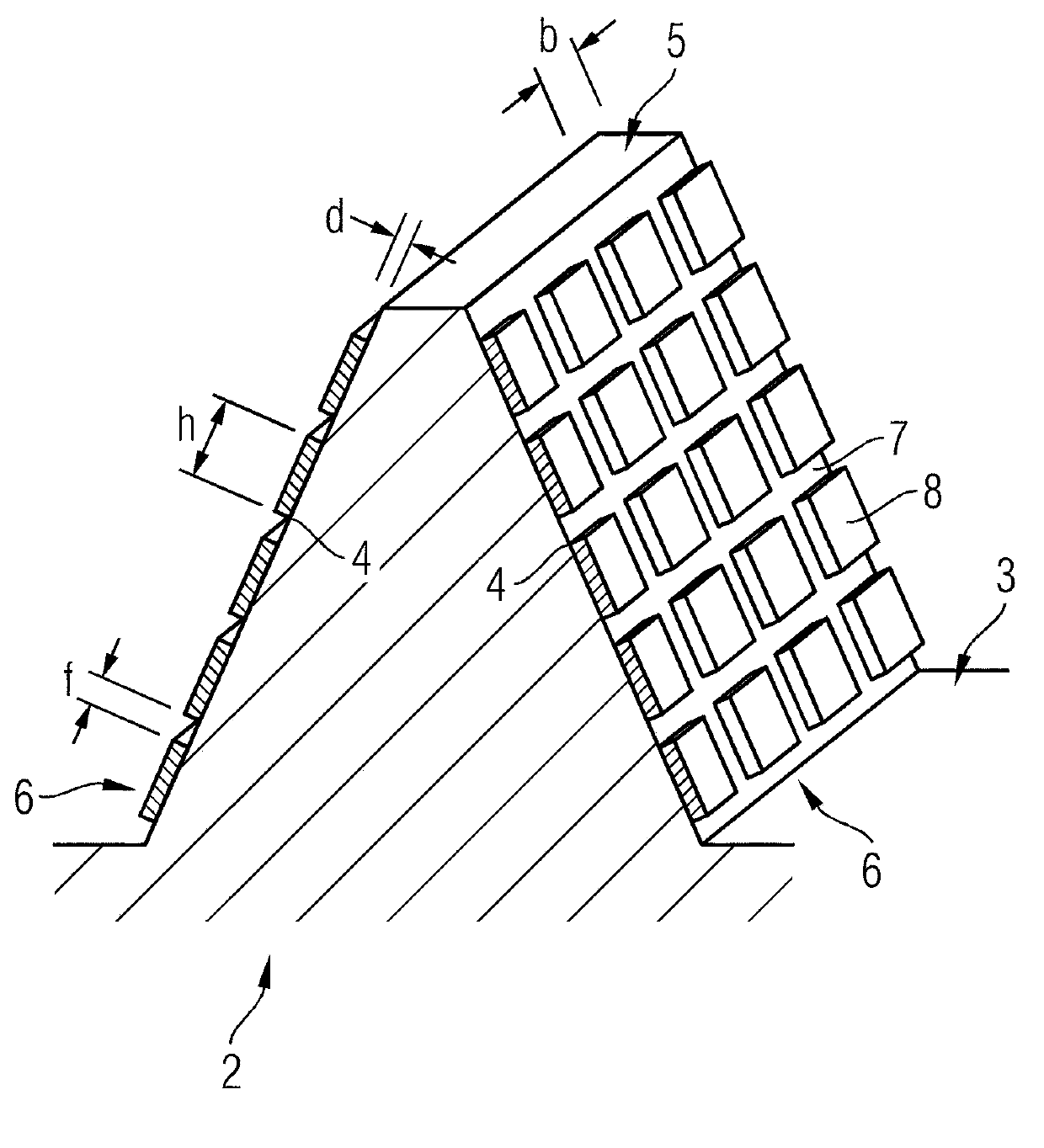

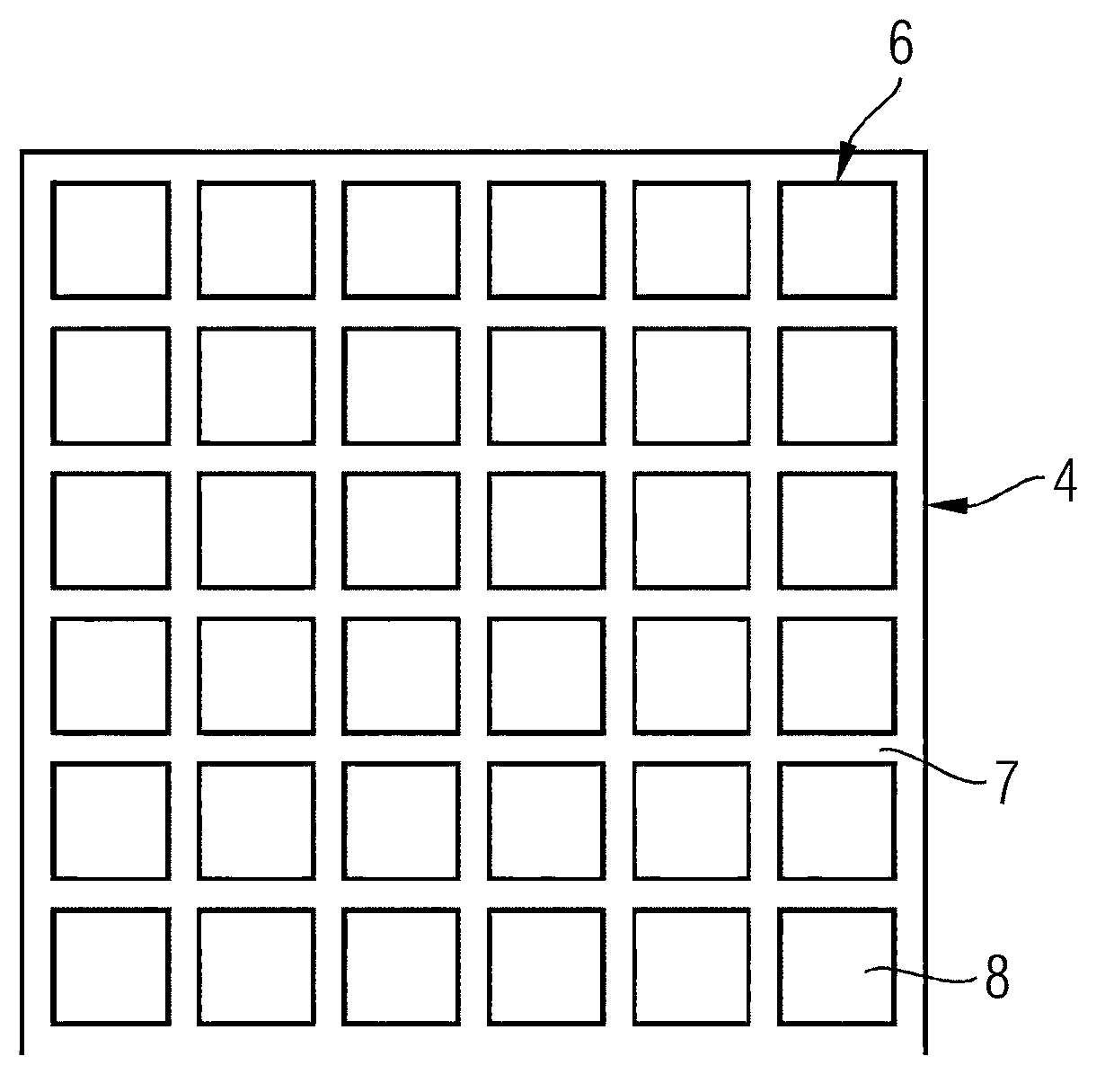

[0029] figure 2 shown in figure 1 A perspective view of the gear tooth 2 of the gear body 10 shown in . A coating 6 is arranged on both tooth flanks 4 of the gear tooth 2 , which coating is harder than the base material of the gear body 10 and thus reduces the wear of the tooth flanks 4 . The coating 6 of thickness d is not formed closed on the tooth flank 4 , but is divided into a plurality of sections 8 . Two adjacent sections 8 are separated from each other by a seam 7 with a seam width f. The segments 8 each have a width b and a height h. The dedendum 3 and the tooth tip 5 are free of coating 6 in order not to limit the elasticity in these regions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com