New production technology of bovine pancreatin

A production process, the technology of bovine pancreatin, which can be applied to pancreatin and other directions, can solve the problems of increasing subsequent processing, environmental pollution, waste, etc., and achieve the effects of good application and promotion prospects, short production cycle and high enzyme activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

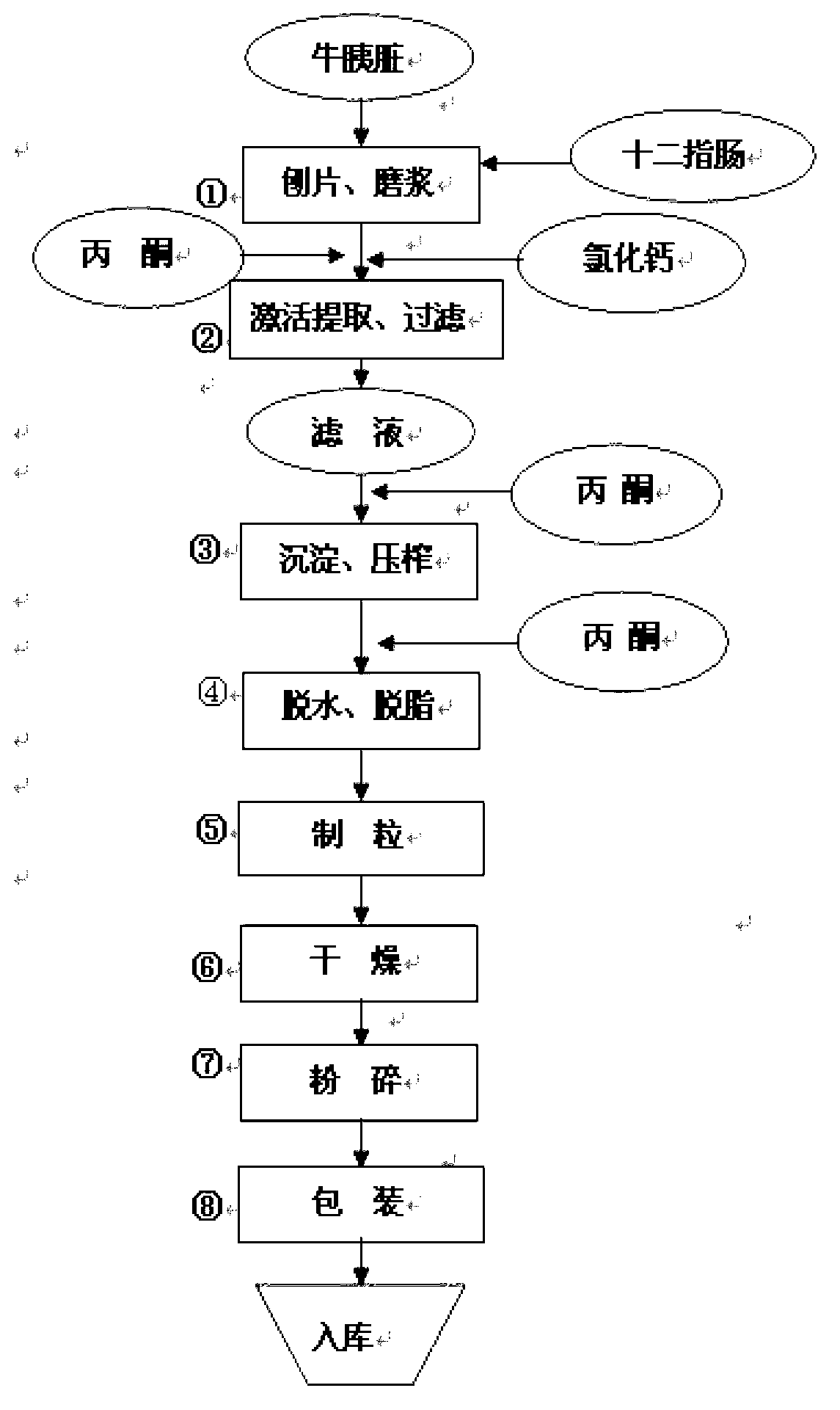

[0027] 1. Production process of bovine pancreatin

[0028] (1) Thawing raw materials, shavings, and refining: accurately weigh the quarantined frozen bovine pancreas and the pig duodenum with 1% weight of the bovine pancreas and shred them with a pancreaser, and then refine them with a refiner.

[0029] (2) Activation, extraction and filtration: Put the pancreatic plasma in the reaction axe, add 0.6% edible calcium chloride and 0.5% pancreatin powder as the activator by weight of the pancreas, and then add 1.5 times the weight of the pancreas with a concentration of 15% The aqueous acetone solution was stirred for 30 minutes, put into the extraction tank, temperature 15 ℃, extraction for 6 hours, filtered with a separator, the filter residue was extracted again in the same way, the two extracts were combined, and the filter residue was discarded to obtain pancreatic milk filtrate.

[0030] (3) Precipitation and pressing: Add acetone (0.85 lighter than the concentration) solution pre-...

Embodiment 2

[0074] Example 2. Production process of bovine pancreatin

[0075] (1) Thawing raw materials, shavings, and refining: accurately weigh the quarantined frozen bovine pancreas and 5% of the weight of the pig duodenum of the bovine pancreas with a pancreas planer, and then use a refiner to refine.

[0076] (2) Activation, extraction and filtration: Put the pancreatic plasma in the reaction axe, add 0.8% pancreatic weight edible calcium chloride and 0.5% pancreatin powder as the activator, and then add 0.5 times the pancreatic weight with a concentration of 10% The acetone solution was stirred for 50 minutes, put into the extraction tank, temperature 20 ℃, extraction for 5 hours, filtered with a separator, the filter residue was extracted again in the same way, the two extracts were combined, and the filter residue was discarded to obtain pancreatic milk filtrate.

[0077] (3) Precipitation and squeezing: Add acetone (0.85 lighter than the concentration) solution pre-cooled to -5°C into ...

Embodiment 3

[0089] Example 3. Production process of bovine pancreatin

[0090] (1) Thawing raw materials, shavings, and refining: accurately weigh the quarantined frozen bovine pancreas and pig duodenum with 3% of the weight of the bovine pancreas and shred them with a pancreaser, and then refine them with a refiner.

[0091] (2) Activation, extraction and filtration: Put the pancreatic plasma in the reaction axe, add 1% edible calcium chloride and 1% pancreatin powder as an activator by weight of the pancreas, and then add 2 times the weight of the pancreas with a concentration of 10% The acetone solution was stirred for 60 minutes, put into the extraction tank, the temperature was 10 ℃, the extraction was 8 hours, filtered with a separator, the filter residue was extracted again in the same way, the two extracts were combined, and the filter residue was discarded to obtain pancreatic milk filtrate.

[0092] (3) Precipitation and squeezing: Add acetone (0.85 lighter than the concentration) solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com