Method for synchronously extracting sage clary essential oil and sclareol from sage clary

A technology of Clarelea essential oil and Sclareol, which is applied in essential oils/fragrances, chemical instruments and methods, and fat production. high extraction rate, low solvent content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

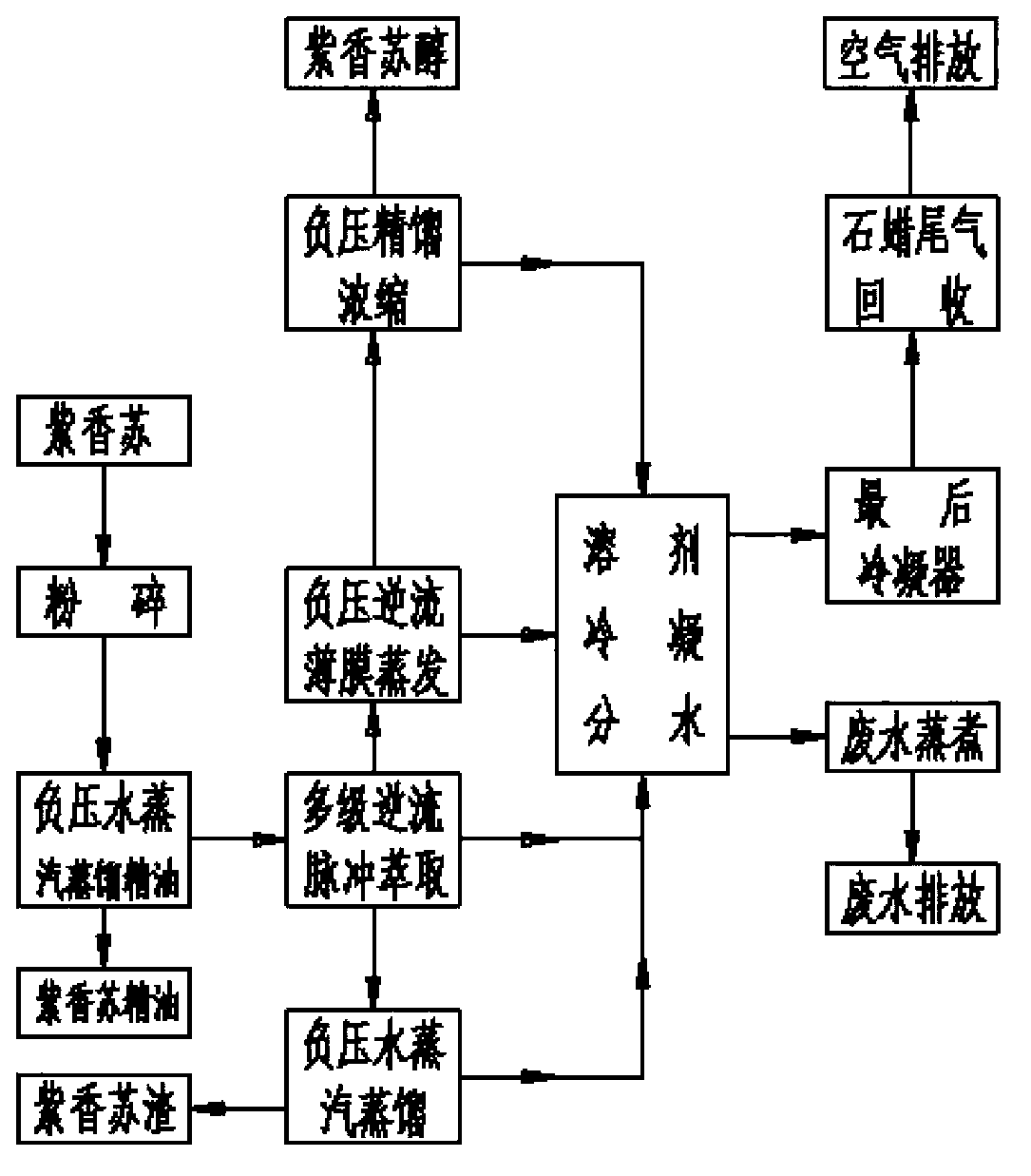

Method used

Image

Examples

Embodiment 1

[0039] (a) The process of crushing Claris perilla is as follows: the raw material of Sclarias perilla is crushed into 20 mm long with a pulverizer;

[0040] (b) Negative pressure steam distillation of Clarisula essential oil: the crushed Claris perilla raw material is transported to the steam distillation tower through a material seal conveyor, and the direct saturated water vapor of 0.05Mpa is passed into the tower, Clarissa essential oil is distilled into a gaseous state by water vapor, then enters the condenser to condense, and after condensation, enters the water distribution tank, and the Clarissa essential oil is separated from water to obtain Clarissa essential oil; the pressure of the rectification tower is -0.04M;

[0041] (c) Multi-stage countercurrent pulse extraction: the sclareus material after extracting the essential oil is transported to the extractor by the sealing conveyor, and sprayed with the extraction solvent containing sclareol at a mass concentration of ...

Embodiment 2

[0050] (a) The crushing process of Claris perilla is as follows: the raw material of Clarysus perilla is crushed into a length of 50 mm with a pulverizer;

[0051] (b) Negative pressure steam distillation of Clarisula essential oil: the crushed Claris perilla raw material is transported to the steam distillation tower through a material seal conveyor, and the direct saturated water vapor of 0.05Mpa is passed into the tower, Clarissa essential oil is distilled into a gaseous state by water vapor, then enters the condenser to condense, and after condensation, enters the water distribution tank, and the Clarix essential oil is separated from water to obtain Clarissa essential oil; the pressure of the rectification tower is -0.03M;

[0052] (c) Multi-stage countercurrent pulse extraction: the sclareus material after extracting the essential oil is transported to the extractor by the sealing conveyor, and sprayed by the extraction solvent containing 1.5% sclareol at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com