Modified alkyd resin as well as preparation method of alkyd resin and double-component matte white finish

A technology of alkyd resin and white topcoat, applied in coatings, polyester coatings, etc., can solve the problems of low photocatalytic efficiency, inability to meet the functional requirements of removing formaldehyde, powdering, etc., and achieve simple operation and stable products , the effect of excellent use characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] Correspondingly, the invention provides a kind of preparation method of modified alkyd resin, comprising:

[0094] reacting an alkyd mixture comprising:

[0095] 210-220 parts by weight of soy oil;

[0096] 250~270 parts by weight of phthalic anhydride;

[0097] 5-7 parts by weight of maleic anhydride;

[0098] The neopentyl glycol of 15~20 parts by weight;

[0099] 135~150 parts by weight of pentaerythritol;

[0100] 0.5~1 parts by weight of color-reducing antioxidant;

[0101] 15-20 parts by weight of water-carrying agent;

[0102] 255-280 parts by weight of diluted solvent;

[0103] 0.5-1.5 parts by weight of anti-aging agent;

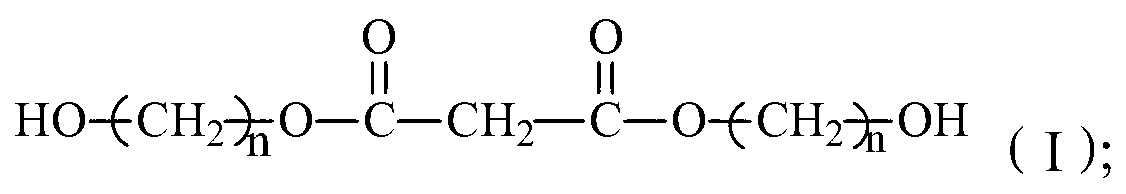

[0104] 60-76 parts by weight of the compound represented by formula (I):

[0105]

[0106] In formula (I), 1≤n≤4.

[0107] The present invention reacts an alkyd mixture containing polyols, organic acids, additives and compounds represented by formula (I) as a raw material to generate a modified alkyd resin, and uses the modified a...

Embodiment 1

[0178] Nitrogen was passed through the empty reactor for 8 minutes in advance, and the nitrogen flow rate was 2m 3 / h;

[0179] Add 50 parts by weight of diethyl malonate, 40 parts by weight of ethylene glycol and 0.05 parts by weight of n-butyl titanate to the above reaction kettle for transesterification reaction. During the whole process of the reaction, nitrogen protection is carried out. , the temperature of the reactor is kept at 150°C by means of heating, and the distillation temperature is controlled to be ≤78.4°C. After 5 hours of reaction, the temperature is raised to 165°C and the reaction is continued for at least 10 minutes. When no distillate is distilled out, the end point is obtained. Compounds represented by formula (I);

[0180] Turn off the heating, put 210 parts by weight of soybean oil, 15 parts by weight of xylene and 0.5 parts by weight of hypophosphorous acid (trade name M070) into the above reaction kettle in sequence, and put 250 parts by weight into...

Embodiment 2

[0188] Nitrogen was passed through the empty reactor for 3 minutes in advance, and the nitrogen flow rate was 5m 3 / h;

[0189] Add 60 parts by weight of diethyl malonate, 50 parts by weight of ethylene glycol and 1.5 parts by weight of n-butyl titanate to the above reaction kettle to carry out the transesterification reaction. During the whole process of the reaction, nitrogen protection is carried out. , the temperature of the reactor is kept at 165°C by heating, and the distillation temperature is controlled to be ≤78.4°C. After 3 hours of reaction, the temperature is raised to 170°C and the reaction is continued for at least 10 minutes. When no distillate distills out, it is the end point, and Compounds represented by formula (I);

[0190] Turn off the heating, put 220 parts by weight of soybean oil, 20 parts by weight of xylene and 1 part by weight of hypophosphorous acid (commercial name M070) into the above reaction kettle in sequence, and put 270 parts by weight into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com