Seal and corresponding sealing assembly

A technology of seals and seals, which is applied in the direction of engine seals, charging systems, passing components, etc., and can solve problems such as damage and destruction of elastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

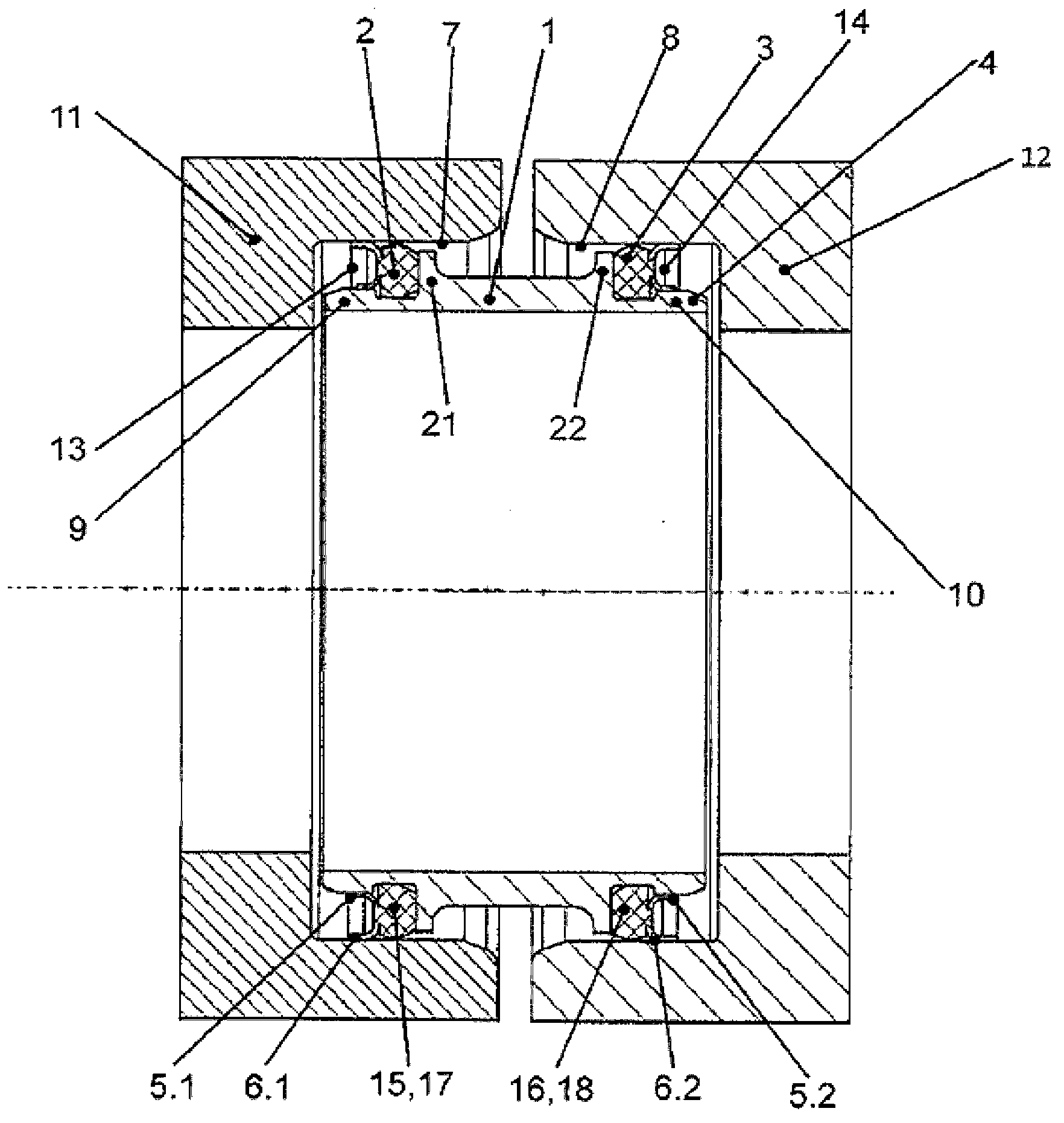

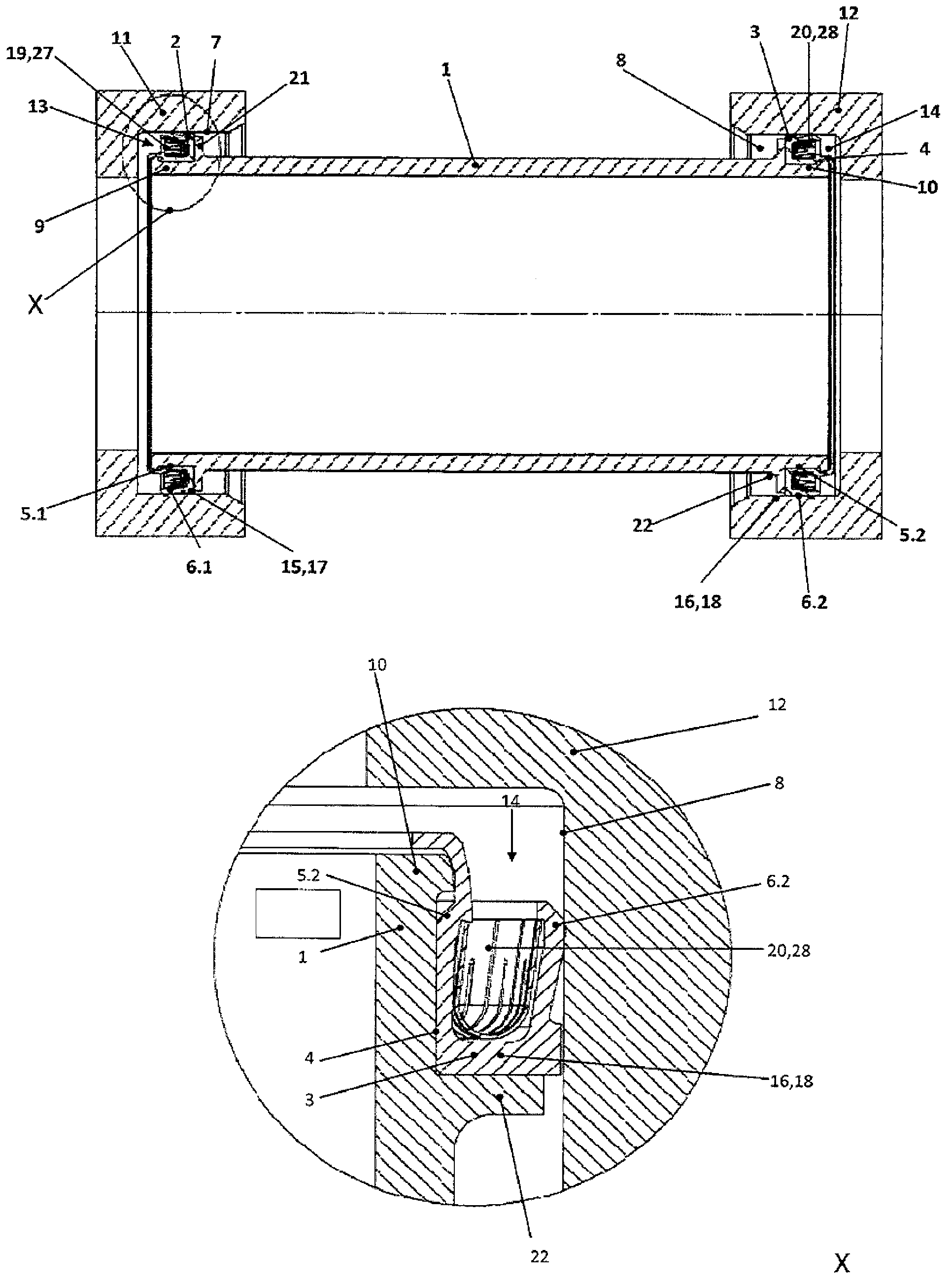

[0032] in Figure 1 to 4 Examples of seals are shown in respectively, where these seals are components of a sealing device.

[0033] In each of the embodiments shown here, the seal includes a tubular carrier 1 made of metal material. The carrier 1 has a groove-shaped groove that opens outward in the radial direction on the outer peripheral side in the region of its two end portions 9, 10, respectively, and an annular sealing body 2 is respectively placed in the groove. 3. The sealing bodies 2 and 3 each hermetically surround the carrier 1.

[0034] The sealing device shown here is used in the charge air system of a truck or car. In order to adapt to this application, the materials used are required to be high temperature resistant. "High temperature resistance" means that the materials used can withstand temperatures up to at least 300°C. For this reason, the use of elastic materials as the annular sealing bodies 2, 3 is excluded.

[0035] In the embodiment shown here, the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com