A kind of down conversion glass substrate and its preparation method and the application in cdte solar cell

A technology for solar cells and glass substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing the conversion efficiency of solar cells, achieve the effects of reducing parasitic absorption, improving conversion efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh germanium oxide, magnesium oxide, aluminum oxide, bismuth oxide, thulium oxide, and 73.5GeO 2 -14MgO-11Al 2 o 3 -0.5Bi 2 O-1Tm 2 o 3 , the weighed raw materials are mixed by ball milling and compacted in a crucible, melted at a temperature of 1550°C for 1.5 hours, stirring evenly during the period, pouring the melted glass onto a copper plate mold, cooling, and annealing Residual stress is removed to obtain a down conversion glass substrate.

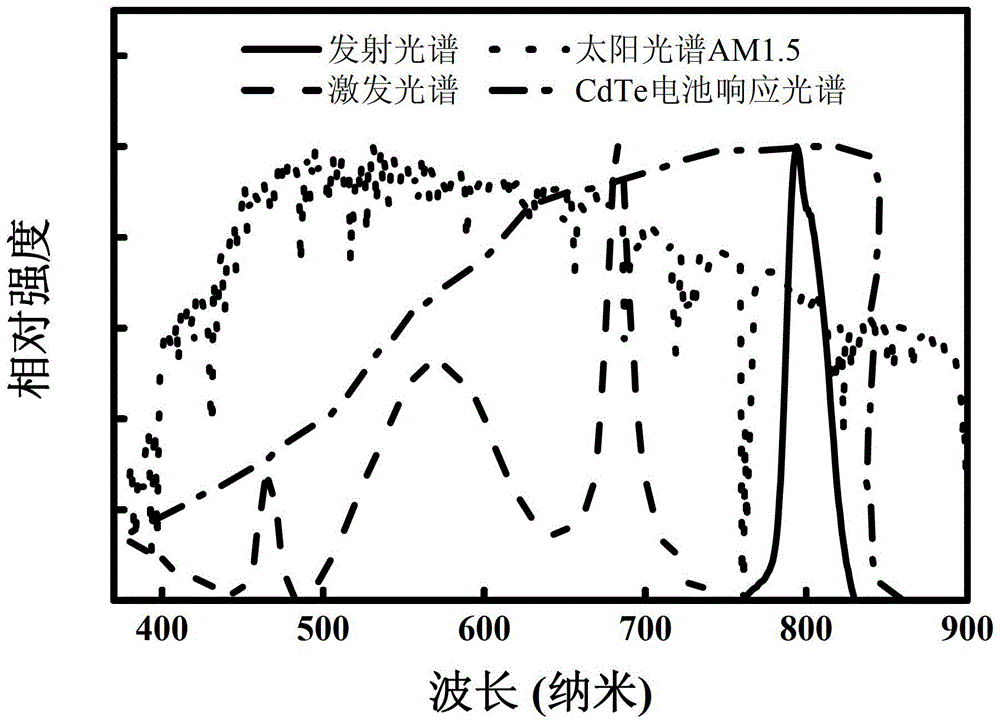

[0028] figure 2 Bi prepared for Example 1 2+ and Tm 3+ Emission spectrum and excitation spectrum of co-doped down-conversion glass substrate, AM1.5 solar spectrum and response curve of CdTe solar cell. It can be seen from the figure that the glass substrate prepared in this embodiment can convert the light of 450nm-750nm into the light of 800nm.

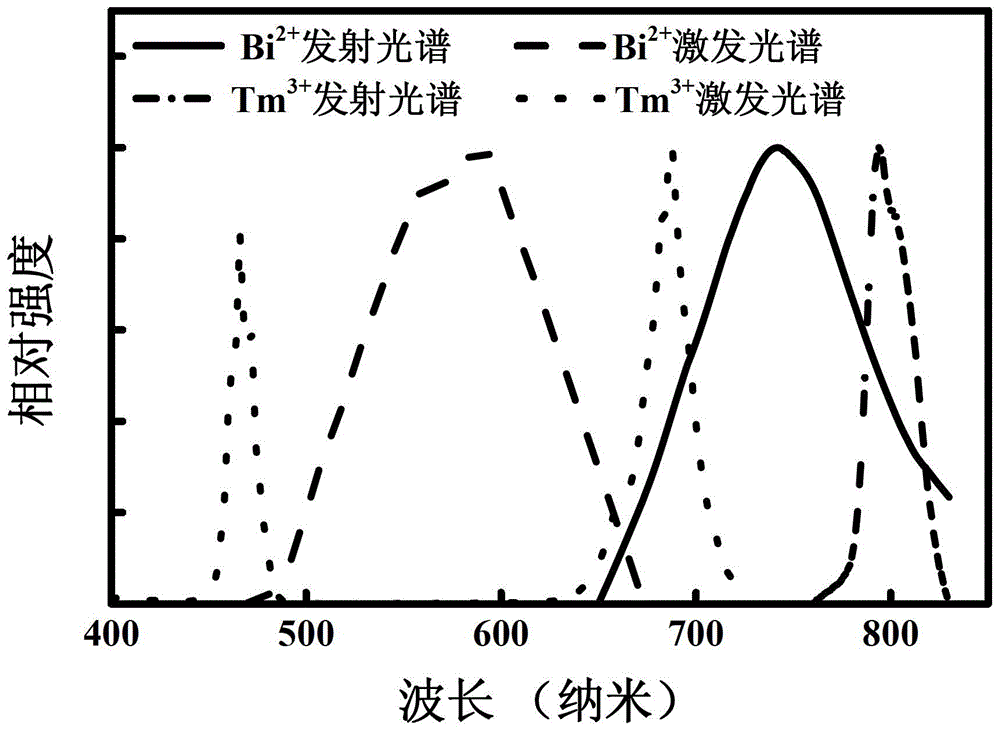

[0029] image 3 Bi prepared for Example 1 2+ Single Blend Tm 3+ In monodoped glass, Bi 2+ Excitation and emission spectra, Tm 3+ emission and excitation spectra. Bi...

Embodiment 2

[0032] Weigh germanium oxide, magnesium oxide, aluminum oxide, bismuth oxide, and thulium oxide respectively, according to the proportion of 65GeO 2 -15MgO-15Al 2 o 3- 2 Bi 2 O-3Tm 2 o 3 , the weighed raw materials are mixed by ball milling and compacted in a crucible, melted at a temperature of 1450°C for 5 hours, stirring evenly during the period, pouring the melted glass liquid onto a copper plate mold, cooling, and annealing Residual stress is removed to obtain a down conversion glass substrate.

Embodiment 3

[0034] Weigh germanium oxide, magnesium oxide, aluminum oxide, bismuth oxide, thulium oxide respectively, according to the proportion of 75GeO 2 -15MgO-7Al 2 o 3 -3Tm 2 o 3 , the weighed raw materials are mixed by ball milling and compacted in a crucible, melted at a temperature of 1650°C for 1 hour, stirring evenly during this period, pouring the melted glass liquid onto a copper plate mold, cooling, and annealing Residual stress is removed to obtain a down conversion glass substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com