A kind of forging process of planet carrier flange forging

A flange forging and planet carrier technology, which is applied in the field of planet carrier flange forging forging technology, can solve the problems of high forming difficulty, increased equipment work load, tissue fiber fracture, etc., so as to improve the material utilization rate and reduce the process pressure. , the effect of dense internal and external tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

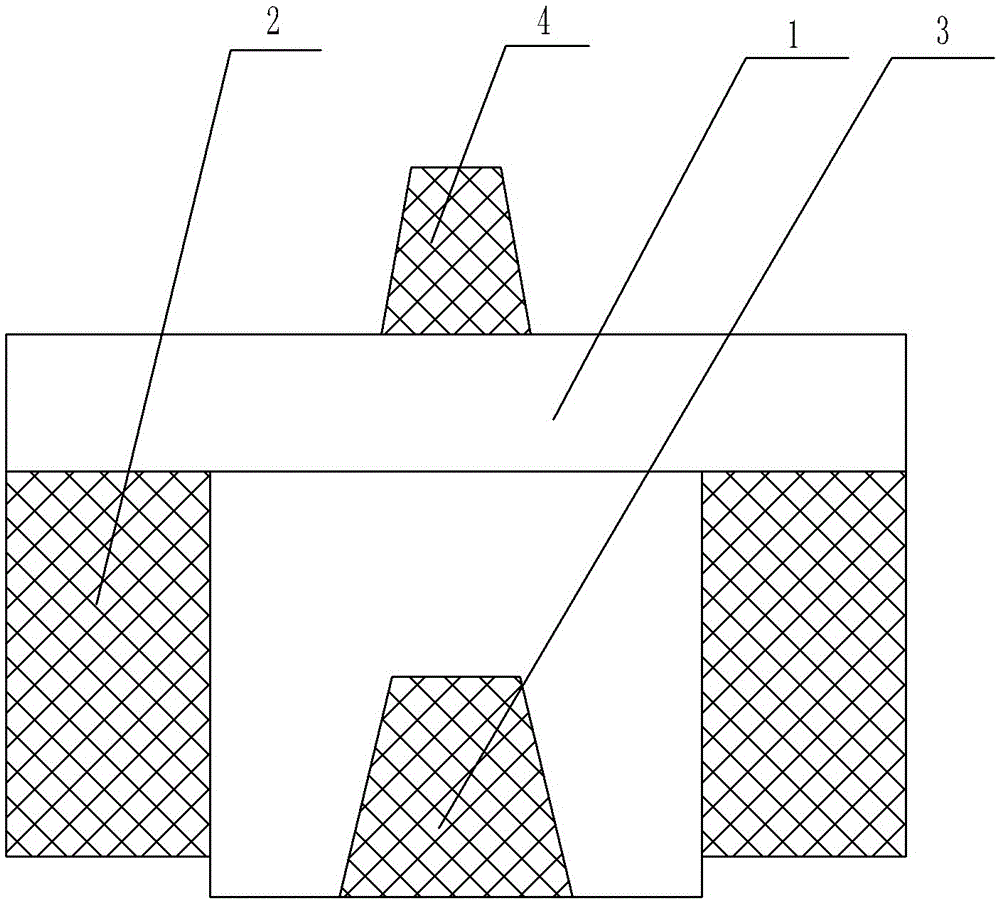

[0018] The following describes the forging process of the planetary carrier flange forging in conjunction with the specific planetary carrier flange:

[0019] See figure 1 As shown, a forging process for a flange forging of a planet carrier comprises the following steps:

[0020] 1. Calculate the size and cutting of forging material:

[0021] (1) Riser pressing and chamfering are carried out on the forgings at 1230-850°C, pressing square 530mm and pouring square 550mm, removing the tail, cutting square 550mm×1110mm;

[0022] (2) Upsetting the forging to Φ800mm at 1230-800°C, using the upper flat plate and the lower turntable, and pulling out 4 times according to the ultra-wide anvil drawing procedure, pressing square and inverted square;

[0023] 2. Upsetting and rounding the outer ring of the forging material: Upsetting and rounding the forgings at 1230-750°C until the diameter is Φ620mm and smooth;

[0024] 3. Punch the blind hole of the forging with the lower punch: put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com