Steel ingot feeder head induction heating and electromagnetic stirring device

An induction heating and electromagnetic stirring technology is applied in the field of induction heating and electromagnetic stirring devices for steel ingot risers. Inclusions, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

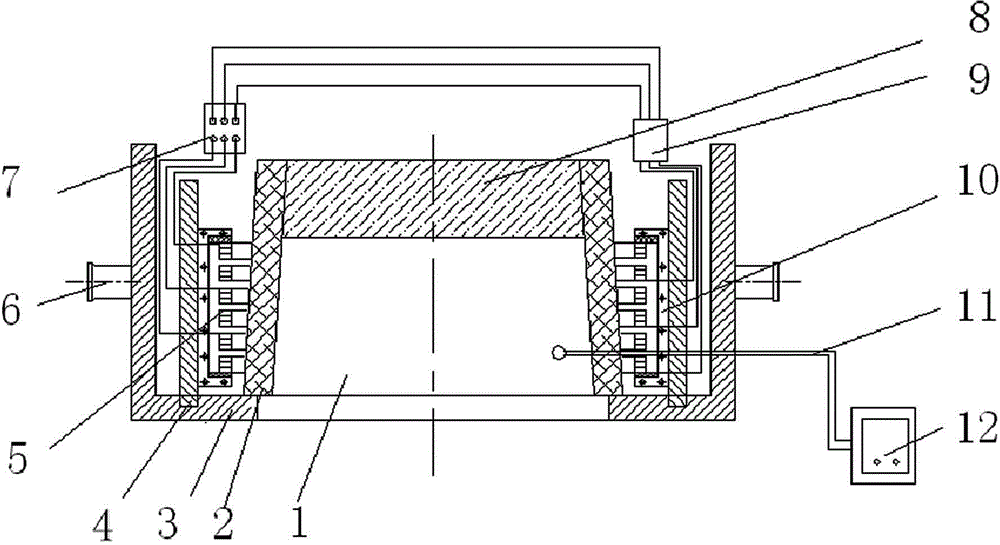

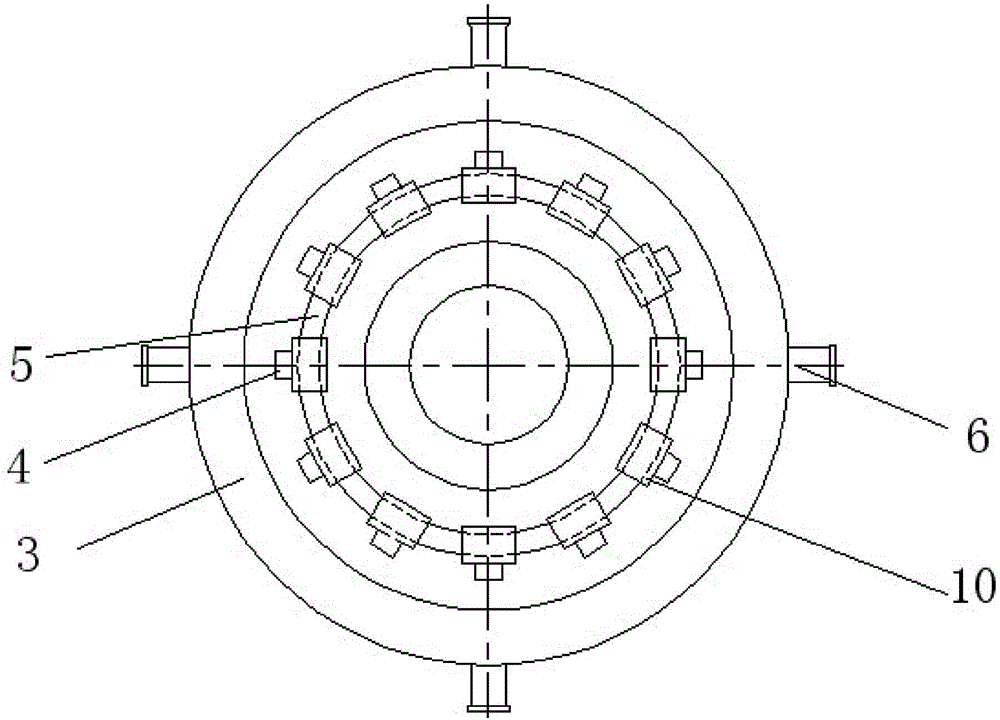

[0029] image 3It is a structural diagram of the steel ingot riser induction heating and electromagnetic stirring device (three-phase six sets of coils) disclosed by the present invention. The steel ingot has a mass of 137 tons, is made of 0Cr13Ni4Mo stainless steel, and has a pouring temperature of 1550°C. The weight of the steel ingot riser is 28 tons, the diameter of the lower surface of the riser is 2550mm, the upper surface of the riser is 2300mm, and the height of the riser is 1200mm. The riser insulation cover 2 has a wall thickness of 120 mm. The riser insulation cover 2 is assembled from refractory bricks and insulation boards. The riser insulation cover is fastened on the support structure, and the outer surface of the side wall of the base 3 is symmetrically provided with lifting lugs 6 . Place the riser insulation cover 2 on the base 3, place six groups of induction coils 5a outside the riser insulation cover 2, there is no ferromagnetic material between the riser ...

Embodiment 2

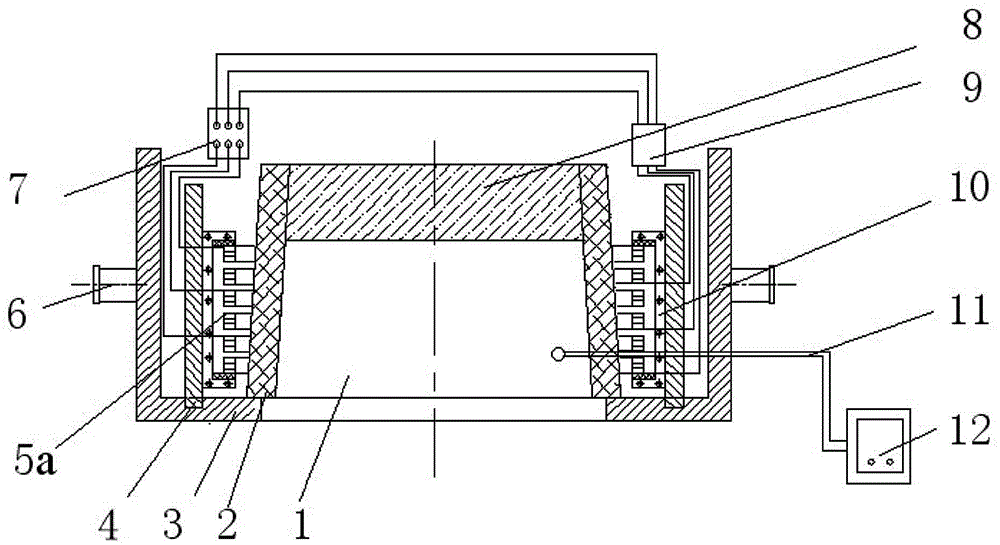

[0032] Figure 4 It is a structural schematic diagram of the steel ingot riser induction heating and electromagnetic stirring device (two-phase four sets of coils) disclosed by the present invention. The steel ingot has a mass of 3 tons, the material is 0Cr13Ni4Mo stainless steel, and the pouring temperature is 1550°C. The weight of the steel ingot riser is 0.5 tons, the diameter of the lower end of the riser is 550mm, the upper end of the riser is 500mm, and the height of the riser is 320mm. The riser insulation cover 2 has a wall thickness of 80 mm. The riser insulation cover 2 is made of refractory bricks and is fastened on the support structure. The outer surface of the side wall of the base 3 is symmetrically provided with lifting lugs 6 . Place the riser insulation cover 2 on the base 3, place four groups of induction coils 5b outside the riser insulation cover 2, there is no ferromagnetic material between the riser insulation cover 2 and the four groups of induction coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com