Nano tio2/montmorillonite composite photocatalytic water treatment material and preparation method thereof

A composite photocatalysis and montmorillonite technology, which is applied in the fields of light water/sewage treatment, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a nano TiO 2 The preparation method of / montmorillonite composite photocatalytic water treatment material comprises the following steps:

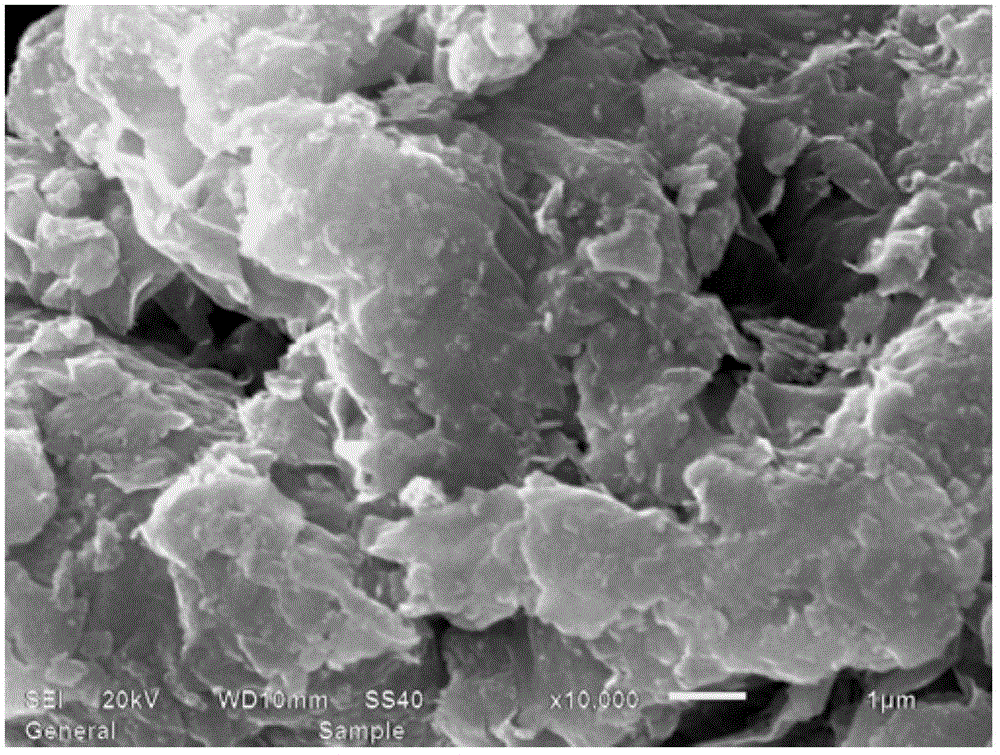

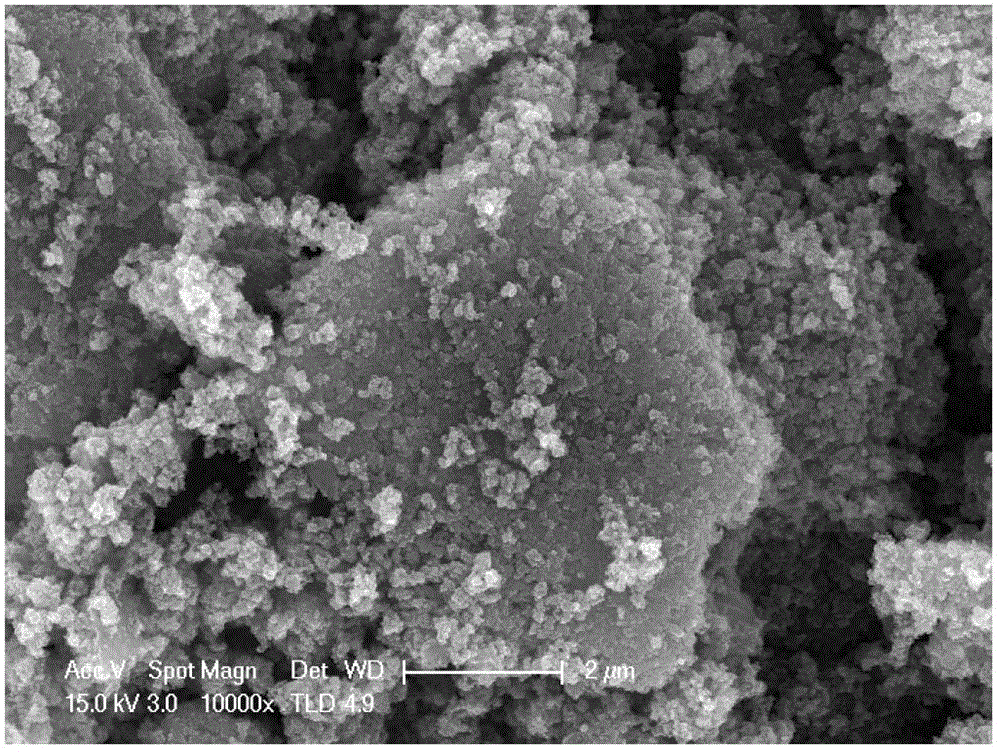

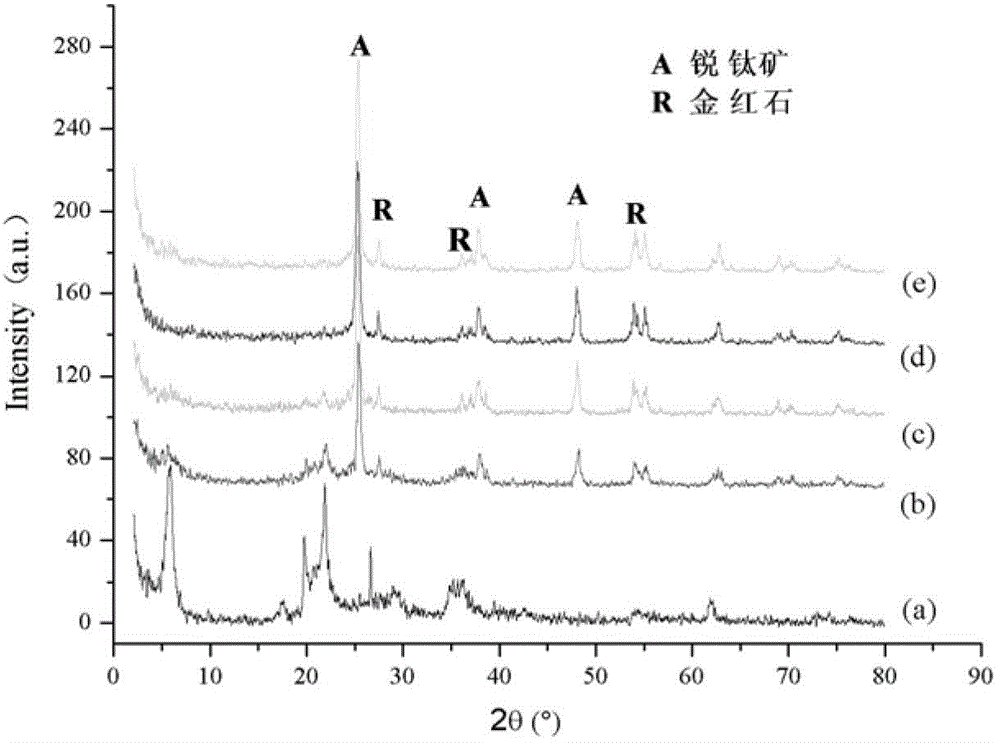

[0047] 1) Weigh 40-98% nano-TiO according to weight percentage 2 and 2~60% montmorillonite, mixed evenly, nano-TiO 2 The particle size is 10~30nm, nano TiO 2 The mass ratio of anatase phase and rutile phase is about 80 / 20; the size of montmorillonite is 12~35μm.

[0048] 2) Mix the nano-TiO homogeneously in step 1) 2 and montmorillonite are placed in absolute ethanol to obtain a slurry;

[0049] 3) The slurry in step 2) is ultrasonically dispersed, and then put into a ball mill for mechanical ball milling to obtain a mixture; the ultrasonic working frequency is 30~50kHz, and the processing time is 10~20min; when the slurry is placed in a ball mill for mechanical ball milling, the ball material Mass ratio=5︰1, ball milling speed is 200~300 rpm, ball milling time is 0.5~3h.

[0050] 4) The mixture is complet...

Embodiment 1

[0053] Weigh 1.6g of industrial finished product German P25 type nano TiO according to weight percentage 2 And 2.4g of montmorillonite, mix well, wherein, nano-TiO 2 The particle size is 20nm, nano TiO 2 The mass ratio of the anatase phase and the rutile phase is about 80 / 20; the size of the montmorillonite is 20 μm. The mixed nano-TiO 2 and montmorillonite in 100ml of absolute ethanol to obtain a slurry; the slurry was ultrasonically dispersed at a frequency of 40kHz for 15min, then put into a ball mill, and mechanically milled for 2h at a milling speed of 250 rpm to obtain a mixture. Ratio=5:1. The anhydrous ethanol contained in the mixture was volatilized at a constant temperature of 105°C until it was completely dry; after heat treatment at 400°C in a muffle furnace for 5 hours, it was cooled to room temperature and taken out, and finally ground to a uniform size of 1000 mesh to obtain a water-treated material.

Embodiment 2

[0055] Weigh 2.4g of industrial finished product German P25 type nano TiO according to weight percentage 2 and 0.6g of montmorillonite, mix evenly, wherein, nano-TiO 2 The particle size is 10nm, nano TiO 2 The mass ratio of the anatase phase and the rutile phase is about 80 / 20; the size of the montmorillonite is 35 μm. The mixed nano-TiO 2 and montmorillonite in 100ml of absolute ethanol to obtain a slurry; the slurry was ultrasonically dispersed at a frequency of 40kHz for 10min, then put into a ball mill, and mechanically milled for 1h at a milling speed of 200 rpm to obtain a mixture. Ratio=5:1. The absolute ethanol contained in the mixture was volatilized at a constant temperature of 105°C until it was completely dry; after heat treatment at 300°C in a muffle furnace for 5 hours, it was cooled to room temperature and taken out, and finally ground to a uniform size of 1000 mesh to obtain a water-treated material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com