Sleeve of drainage tube

A drainage tube and cannula technology, applied in the field of medical devices, can solve problems such as easy introduction of bacteria, wound infection and suppuration, unresolved blockage, etc., to achieve the effect of preventing blockage, good barrier effect, and maintaining smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

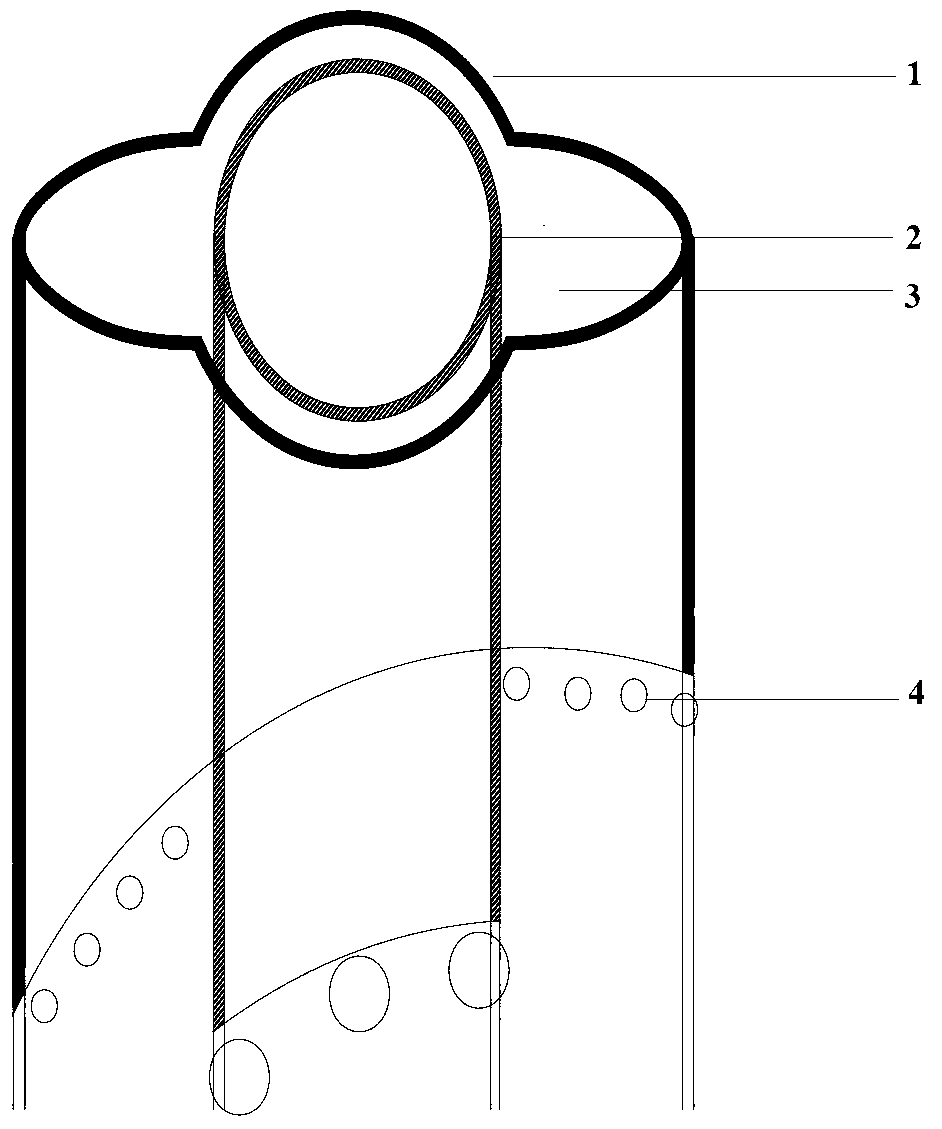

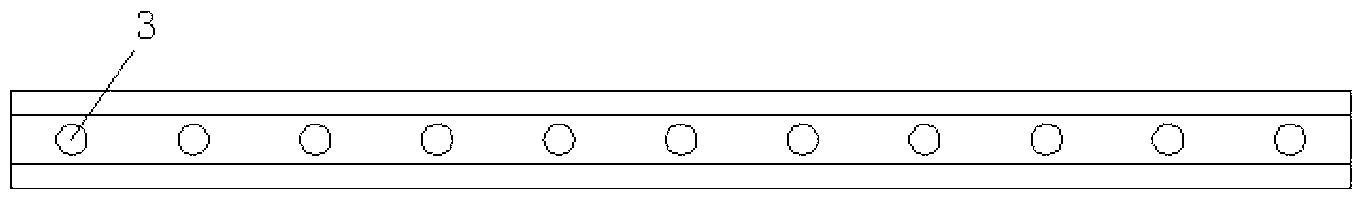

[0035] The polyglycolide copolymer (PLGA, with a molecular weight of 70,000) with a molar ratio of glycolide / lactide of 20 / 30 was injection molded by an injection molding machine, wherein the temperature of the injection molding machine was set at 150°C, and the injection pressure was 80MPa, clamping force 100T, injection speed 2s, cooling time 30s, pressure holding time 10s, one-time injection molding, to obtain a biodegradable outer tube with a thick middle and flat sides, the thickness of the tube wall is 0.8mm, usually The diameter of the hole is 2mm, and the drainage tube is placed in the biodegradable outer tube to obtain the drainage tube casing.

Embodiment 2

[0037] Racemic polylactic acid with a molecular weight of 80,000 is used as the base material for injection molding through an injection molding machine. The temperature of the injection molding machine is set at 160°C, the injection pressure is 80MPa, the clamping force is 100T, the injection speed is 1s, and the cooling time is 30s, the pressure holding time is 10s, one-time injection molding, the biodegradable outer tube with thick middle and flat sides is obtained, the thickness of the tube wall is 0.8mm, the diameter of the through hole is 2mm, and the drainage tube is placed in the biodegradable outer tube , the drainage tube cannula can be obtained.

Embodiment 3

[0039] The glycolide / lactide / polyethylene glycol copolymer with a molar ratio of mPEG / PLGA of 80 / 20 and a molecular weight of 60,000 was used as a base material for injection molding by an injection molding machine, and the temperature of the injection molding machine was set at 100 ° C. The injection pressure is 80MPa, the clamping force is 100T, the injection speed is 1s, the cooling time is 30s, and the holding time is 10s. One-time injection molding, the biodegradable outer tube with thick middle and flat sides is obtained, and the thickness of the tube wall is 0.8mm. , the diameter of the through hole is 2 mm, and the drainage tube is placed in the biodegradable outer tube to obtain the drainage tube casing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com