Polyurethane elastomer phononic crystal noise-reducing film and preparation method thereof

A polyurethane elasticity, sub-crystal technology, applied in chemical instruments and methods, synthetic resin layered products, transportation and packaging, etc. High efficiency, good barrier effect and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

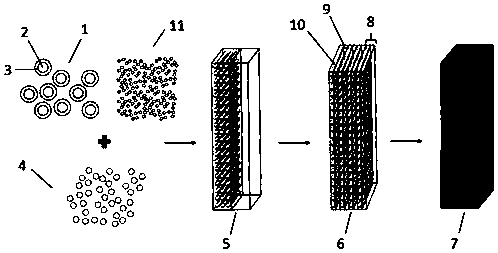

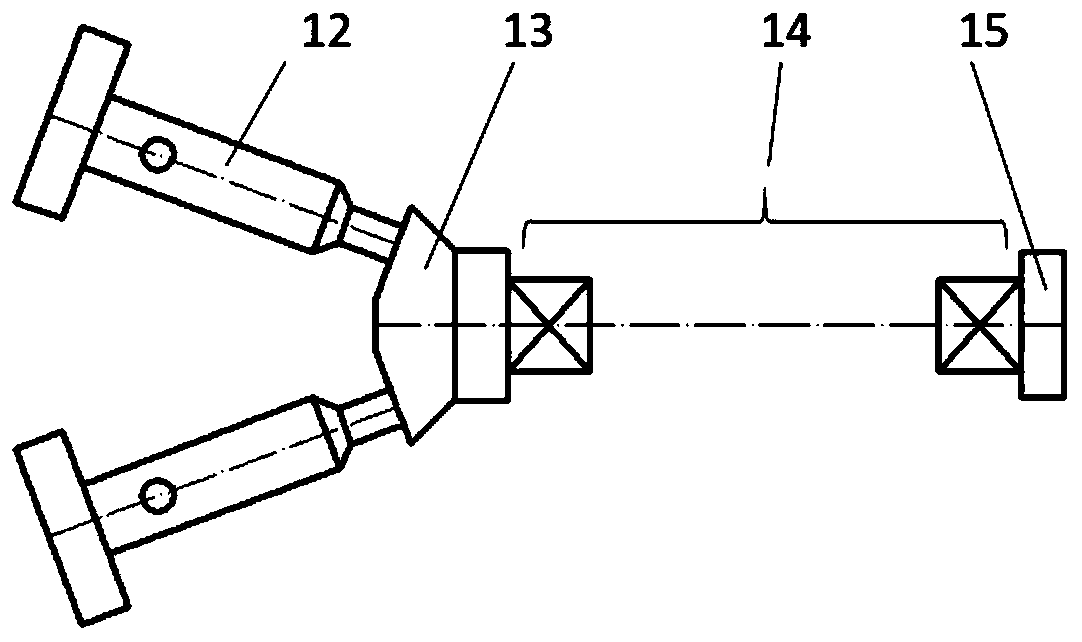

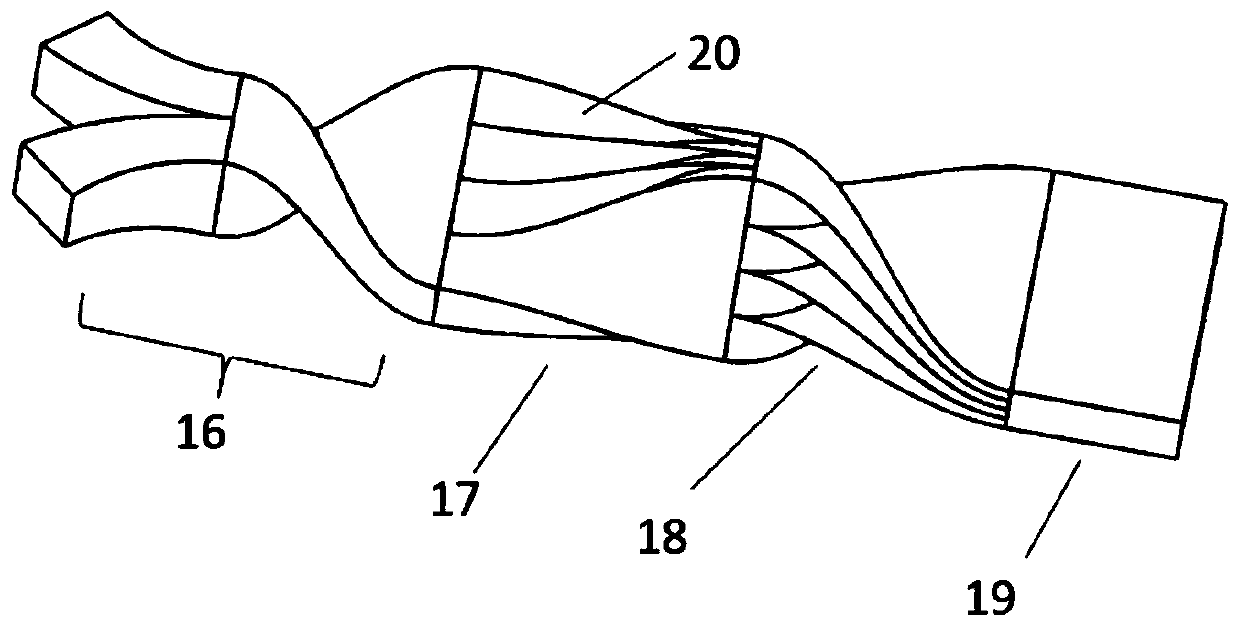

[0019] The polyurethane elastomer phononic crystal sound-absorbing membrane of the present invention includes at least four periodic components 8, and each periodic component 8 is composed of a polyurethane layer 9 and a vibrator layer 10, wherein the vibrator layer 10 is covered by a polymer 11 with a large number of microbead vibrators 1, the microbead vibrator 1 is composed of a metal microbead 2 covered with a layer of soft elastomer 3; the melt lamination equipment required for its manufacturing method consists of an extrusion unit 12, a confluence unit 13, a lamination unit 14, and a head unit Composed of 15, the two extrusion units 12 are respectively connected with the confluence unit 13, the confluence unit 13 is followed by one or more lamination units 14, and the last lamination unit 14 is connected with the head unit 15; the confluence unit 13 has a confluence channel 16 , there are stacked flow channel I 17 and stacked flow channel II 18 in the stacking unit 14, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com