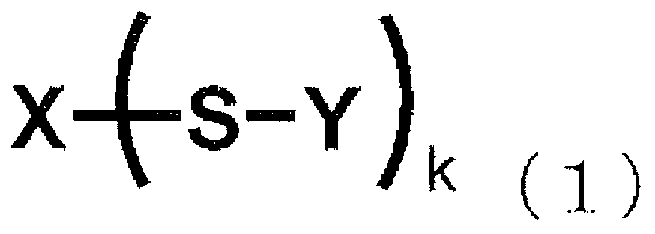

Curable resin composition

A technology of curable resin and composition, applied in the direction of coating, etc., can solve the problems of large curing shrinkage, small radius of curvature, bad condition, etc., and achieve the effect of low curling and high pencil hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

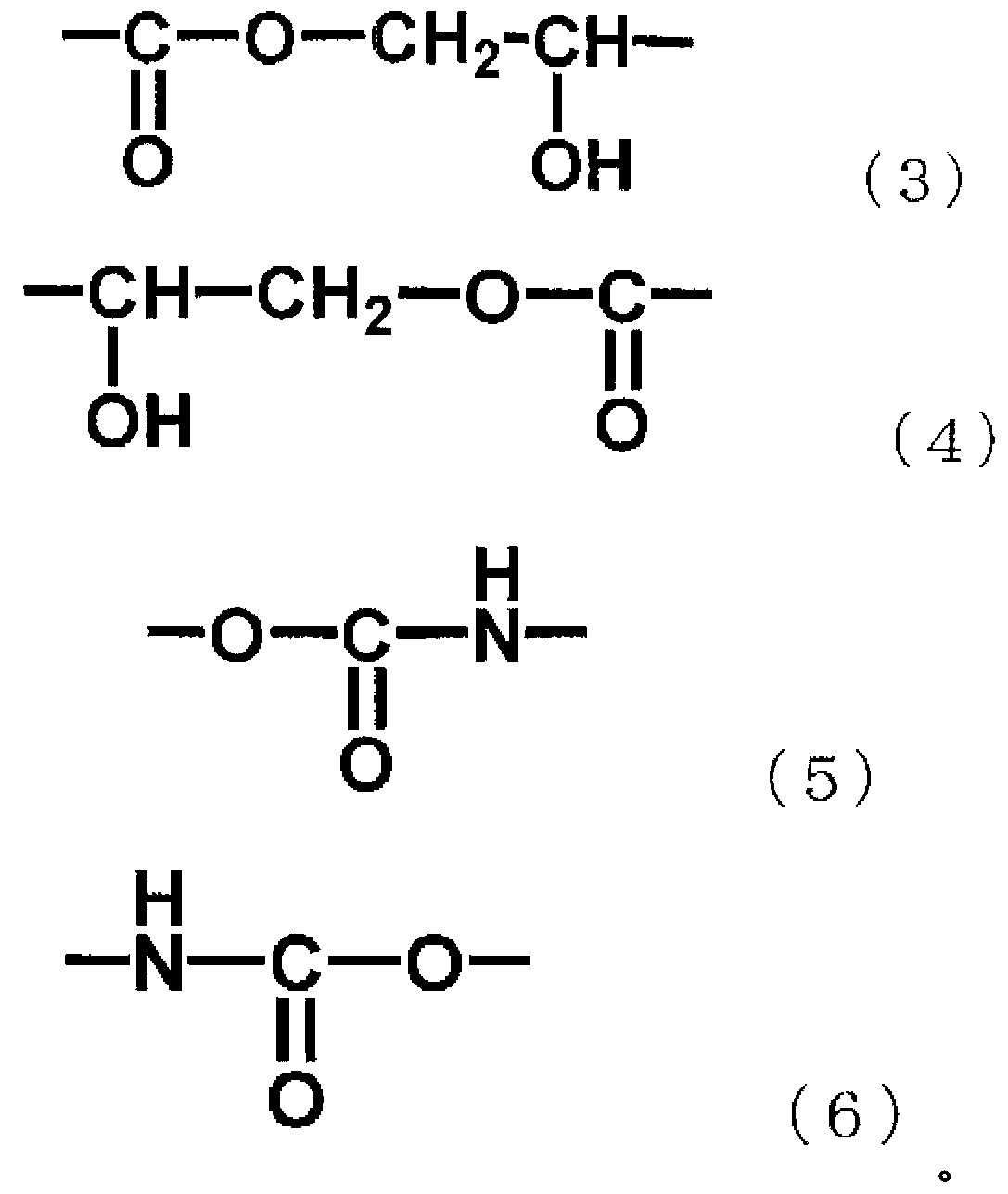

Method used

Image

Examples

Embodiment

[0148] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples.

[0149] (1) Synthesis of Copolymer (A)

manufacture example 1

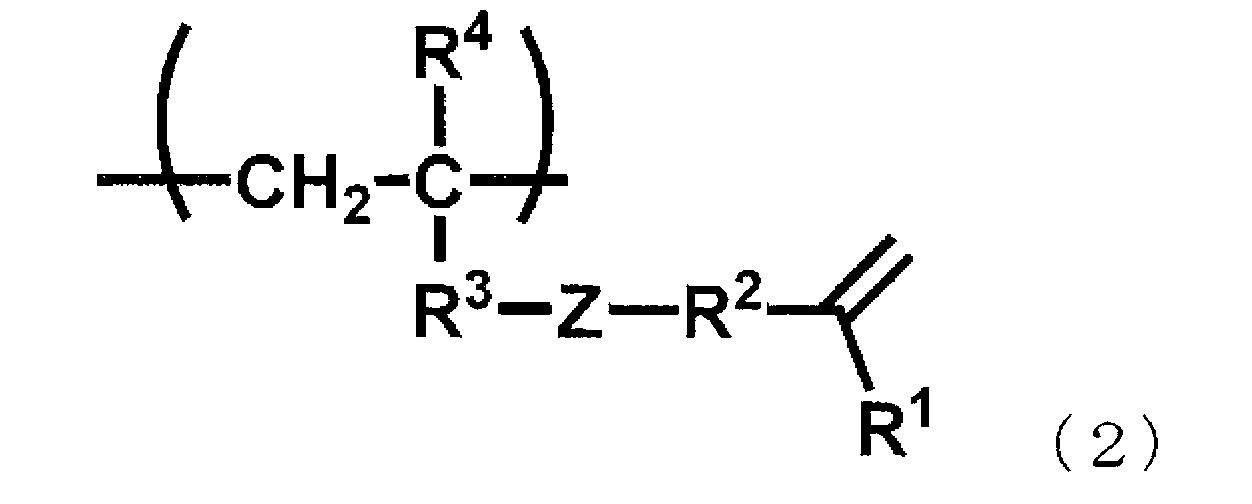

[0150] [Production Example 1]: Synthesis of Copolymer (P-1) with Unsaturated Groups in Side Chains

[0151] In a reaction vessel equipped with a thermometer, a stirring bar, a reflux cooler and a dropping funnel, add a 50% / 50% mixed solution of propylene glycol monomethyl ether and methyl ethyl ketone (hereinafter, abbreviated as PGME, MEK mixed solution) After 115.0 parts by mass and 3.0 parts by mass of pentaerythritol tetrakis(3-mercaptopropionate) (manufactured by SC Organic Chemicals Co., Ltd., PEMP), it was heated to about 80°C. Therein, 97.6 parts by mass of methyl methacrylate (hereinafter, abbreviated as MMA), 72.6 parts by mass of acrylic acid (hereinafter, abbreviated as Aa), cyclohexane methacrylate (hereinafter, abbreviated as CHMA) were added dropwise over 2 hours. ) 43.1 parts by mass, 2-ethylhexyl methacrylate (hereinafter, abbreviated as 2EHMA) 13.6 parts by mass, azobisisobutyronitrile (hereinafter, abbreviated as AIBN) 0.9 parts by mass, 2-ethylhexylthioglyc...

manufacture example 2~6

[0153] Except that the components used and their usage ratios are shown in Table 1, the same method as in Production Example 1 was used to obtain copolymers (P-2) to (P-6) having unsaturated groups in their side chains. . MAa in Table 1 represents methacrylic acid, and 4-HBAGE represents 4-hydroxybutyl acrylate glycidyl ether. MAa was added instead of Aa, and 4-HBAGE was added instead of GMA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com