A kind of top cover for power battery with aluminum shell

A power battery and top cover technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as fire, secondary safety hazards, and ignition, and achieve safety hazards, good safety performance, and guaranteed safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

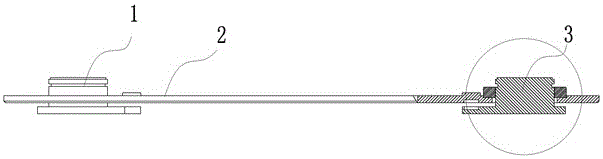

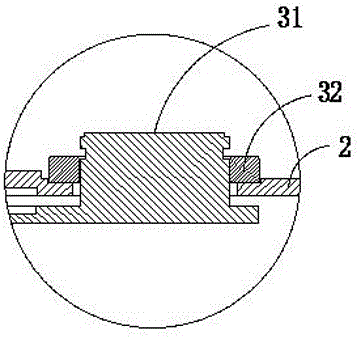

[0027] Example 1, such as figure 1 As shown, a top cover for an aluminum case power battery provided in this embodiment includes a top cover sheet 2 made of aluminum, and the top cover sheet 2 is provided with two electrode introduction holes, and the two electrode introduction holes are respectively connected with Negative pole structure 1 and positive pole structure 3, wherein, such as figure 2 As shown, the positive pole structure 3 includes a positive pole 31 and a high temperature resistant resistor 32. The positive pole 31 passes through the electrode introduction hole and is insulated and connected with the top cover sheet 2. The positive pole 31 and the top cover sheet 2 are also connected through a high temperature resistant The resistor 32 is electrically connected, and the material of the high temperature resistance resistor 32 is silicon carbide, its resistance value is 10 ohms, and its maximum temperature is greater than 600°C. The high temperature resistant res...

Embodiment 2

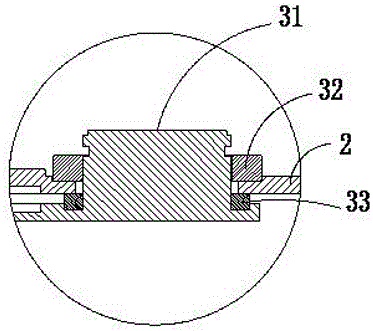

[0028] Embodiment 2 is different from Embodiment 1 in that the resistance value of the high temperature resistant resistor 32 is 50 ohms, and, as image 3 As shown, a high temperature resistant insulating sealing ring 33 is also provided between the bottom of the positive pole 31 and the lower surface of the top cover sheet 2 .

[0029] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0030] Embodiment 3 is different from Embodiment 1 in that the resistance value of the high temperature resistant resistor 32 is 100 ohms, and, as Figure 4 As shown, a high-temperature resistant insulating sealing ring 33 is also provided between the bottom of the positive pole 31 and the lower surface of the top cover sheet 2, and a retaining spring 34 is provided between the positive pole 31 and the high-temperature resistance 32. The key connection of the spring 34 realizes the firm connection of the two.

[0031] Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com