Apparatus for measuring wetting condition of surface of metal in oil/water double phase flow system, and method thereof

A metal surface, two-phase flow technology, applied in measurement devices, surface/boundary effects, instruments, etc., to achieve the effect of easy disassembly, small end surface area, and small distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The size and connection of each part of the present invention:

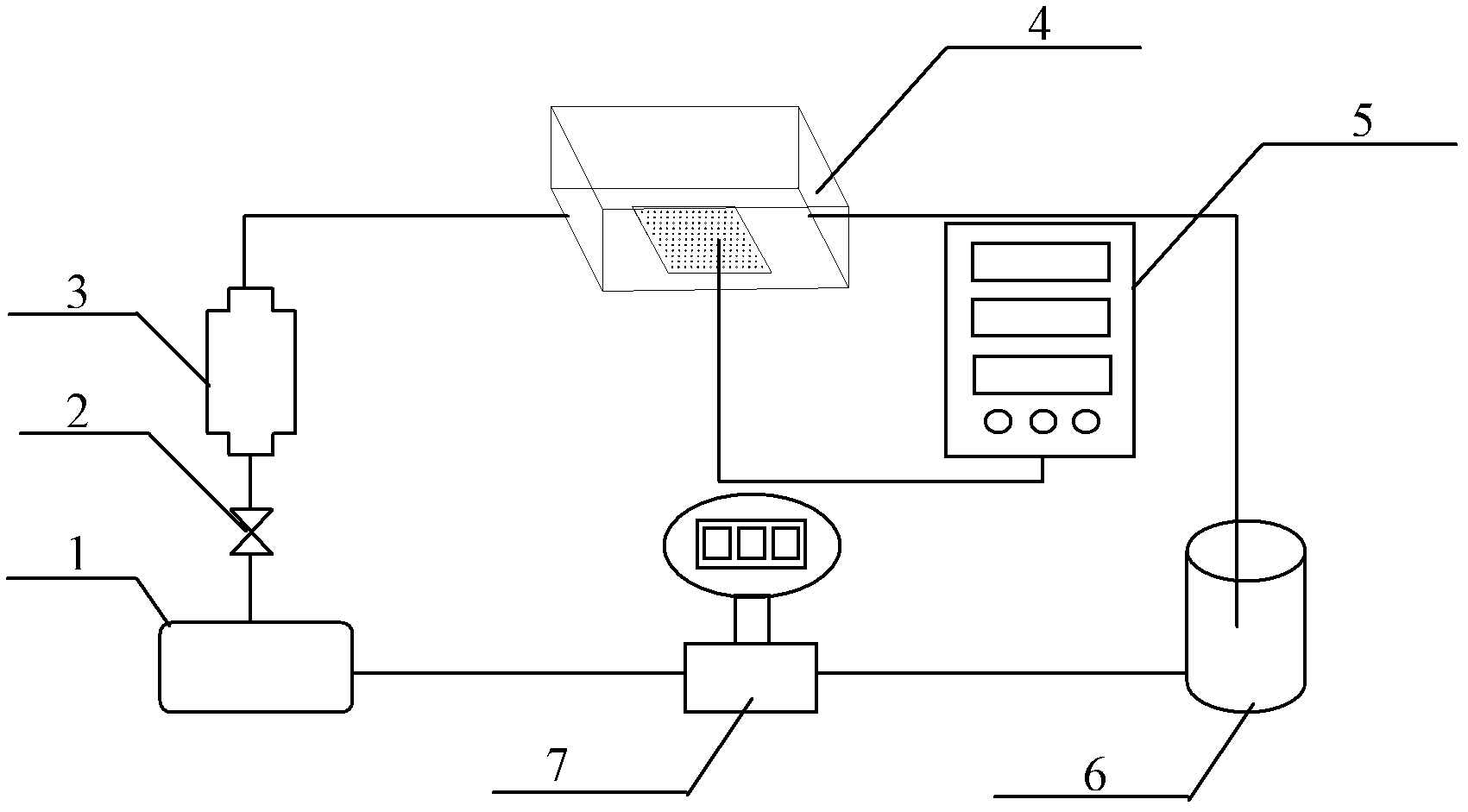

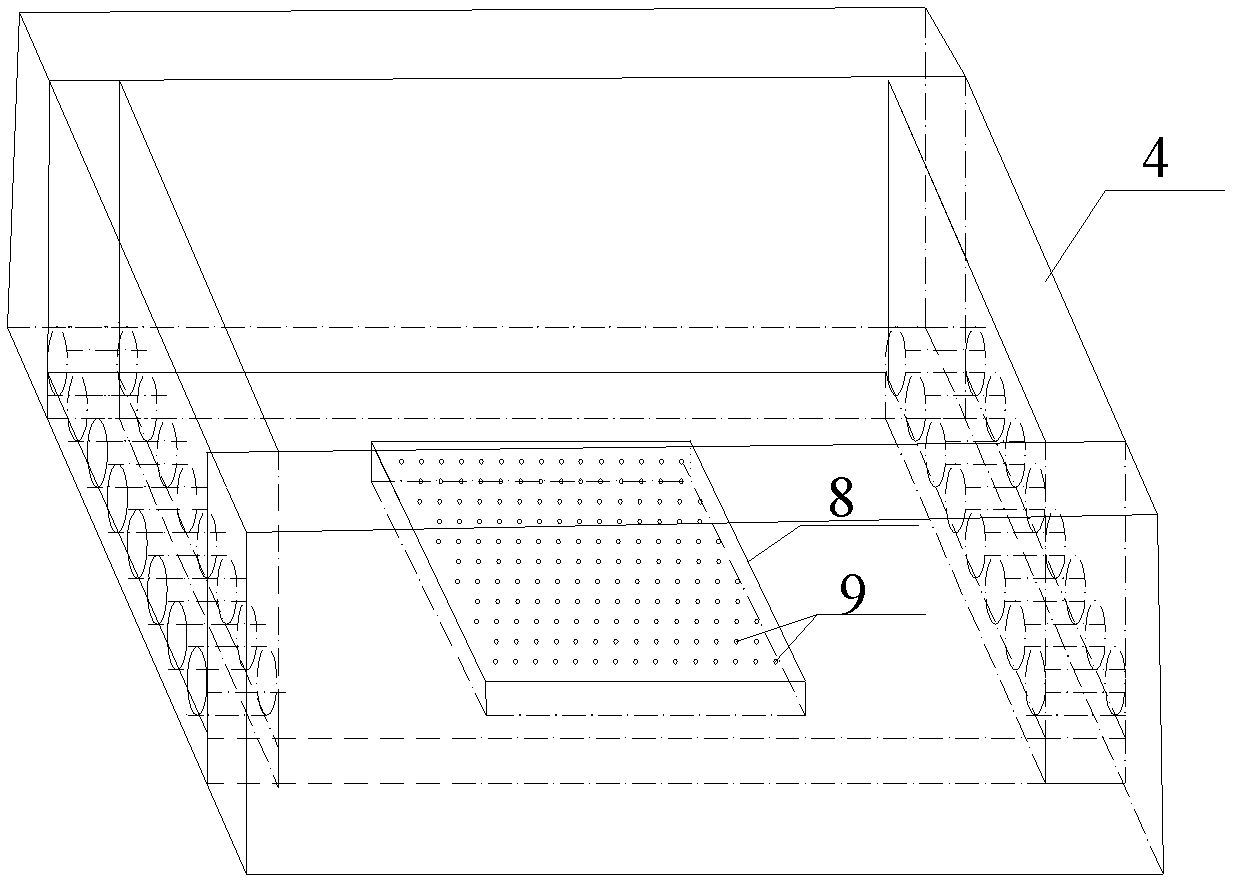

[0054] Such as figure 1 As shown, the device for measuring the wetting state of the metal surface in the oil / water two-phase flow system of the present invention includes a circulating pump 1, a flow rate regulating valve 2, a disc separator 3, a sample tank 4, a signal acquisition and display circuit 5, a storage Liquid tank 6, volume flow meter 7, test sample 8 and miniature conductivity sensor 9.

[0055] The circulation pump 1 is a 750W pipeline centrifugal pump; the liquid storage tank 6 is a cylindrical container of Ф150×300, made of plexiglass, and the lower part of the cylinder wall has a Ф2.54 outlet hole; the disc water separator 3 is made of stainless steel Manufactured, including one water inlet 10 of Ф2.54 and eight water outlets 12 of Ф10, and a cylindrical buffer chamber 11 of Ф85 between the water outlet 12 and the water inlet 10; the water inlet 10 enters from one end surface of the buffe...

Embodiment 2

[0058] The method for measuring the wetting state of the metal surface in the oil / water two-phase flow system of the present invention:

[0059] Take the measurement of the wetting state of the surface of a stainless steel test sample during the flow of a certain oil / water two-phase system as an example:

[0060] 1. Sample preparation

[0061] The test liquid is a mixture of distilled water with a volume percentage of 20% and No. 3 white oil with a volume percentage of 80%; the test sample is made of 304 stainless steel through machining.

[0062] 2. Measurement process

[0063] 1) Pour the test liquid prepared according to the predetermined volume ratio into the liquid storage tank 6, start the circulation pump 1, and wait for the liquid oil / water two-phase to mix and circulate smoothly in the whole device;

[0064] 2) Power up the signal processing and display circuit 5, and the light-emitting diode starts to flash;

[0065] 3) Adjust the flow rate regulating valve 2 so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com