Silk degumming/scouring agent and applications thereof

A silk degumming and scouring agent technology, applied in the field of cocoon degumming agent or silk scouring agent, can solve the problems of poor elasticity of silk floss, environmental pollution of machine-made silk floss sheets, unrecoverable sericin, etc., so as to avoid waste, avoid environmental pollution, The effect of high-efficiency recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of strong alkaline electrolyzed water: add ordinary tap water to the electrolytic cell, or add a small amount of electrolysis accelerator such as sodium chloride to the ordinary tap water, turn on the power to make the electrolytic cell work, collect the alkaline electrolyzed water at the cathode outlet, adjust the size of the current or The flow rate of tap water was used to obtain electrolyzed water with a pH of about 11.50. After filtering or standing overnight, the filtrate or supernatant was used for all experiments in the present invention, and it was generally sealed and stored in a refrigerator at 4°C for future use.

[0037] Put the shaved cocoon, silk fiber or waste silk directly into the strong alkaline electrolyzed water prepared by the Sheng, boil and degumming for 10-60 minutes to obtain sericin solution and silk fibroin from which sericin has been removed.

Embodiment 2

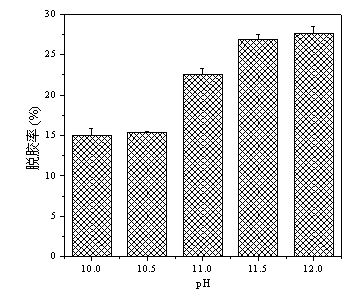

[0039] Put tap water in the electrolytic cell, prepare a series of strong alkaline electrolyzed water with pH of 10.0, 10.5, 11.0, 11.5, 12.0, and conduct boiling degumming test with common silkworm cocoon shell (bath ratio 1:40, W / V ). Divided into the above 5 groups according to the difference of pH value, each group was repeated three times, each group weighed about 2.0 g of clean ordinary cocoon shells, and recorded the weight of the cocoon shells. Put the weighed cocoon shells into the triangular flask respectively, add electrolyzed water with different pH values according to the bath ratio of 1:40, and boil. Stir constantly during the boiling process to make the heating even. After boiling for 20 min, the silk was taken out and rinsed with double distilled water, wrung out and dried in an oven at 80°C. After 2 h, it was taken out and weighed to calculate the degumming rate. The formula for calculating the degumming rate was:

[0040] Degumming rate = (weight of cocoon...

Embodiment 3

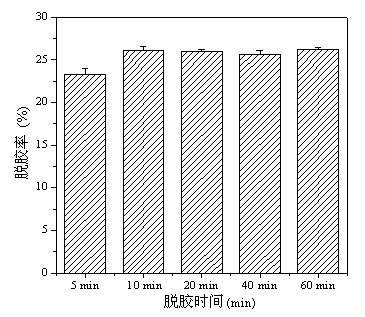

[0043] Electrolyzed water with a pH of about 11.50 was prepared according to Example 1. Weigh clean common cocoon shells, divide them into 5 groups, do three repetitions for each group, weigh about 2.0 g of clean common cocoon shells for each group, and record the weight of the cocoon shells. Put the weighed cocoon shells into the triangular flask, and add electrolyzed water with a pH of 11.50 according to the bath ratio of 1:40 (W / V). Boiling degumming, stirring constantly during the boiling process, so that the heating is even. After 5, 10, 20, 40, and 60 min, take out the silk and rinse it with double-distilled water, wring it out, and put it in an oven at 80°C for drying treatment. After 2 hours, take out the silk and weigh it to calculate the degumming rate, as shown in Figure 2 It is the experimental result graph of the effect of strong alkaline electrolytic water degumming time on silk degumming. Boiling degumming in strong alkaline electrolytic water with a pH of 11.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com