Gold nano-star @ quantum dot composite cell probe with photothermal and fluorescence enhancement dual-functions and preparation method and applications thereof

A gold nano-composite technology, applied in biochemical equipment and methods, medical preparations containing active ingredients, nanotechnology for materials and surface science, etc., can solve the problem of fluorescence intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

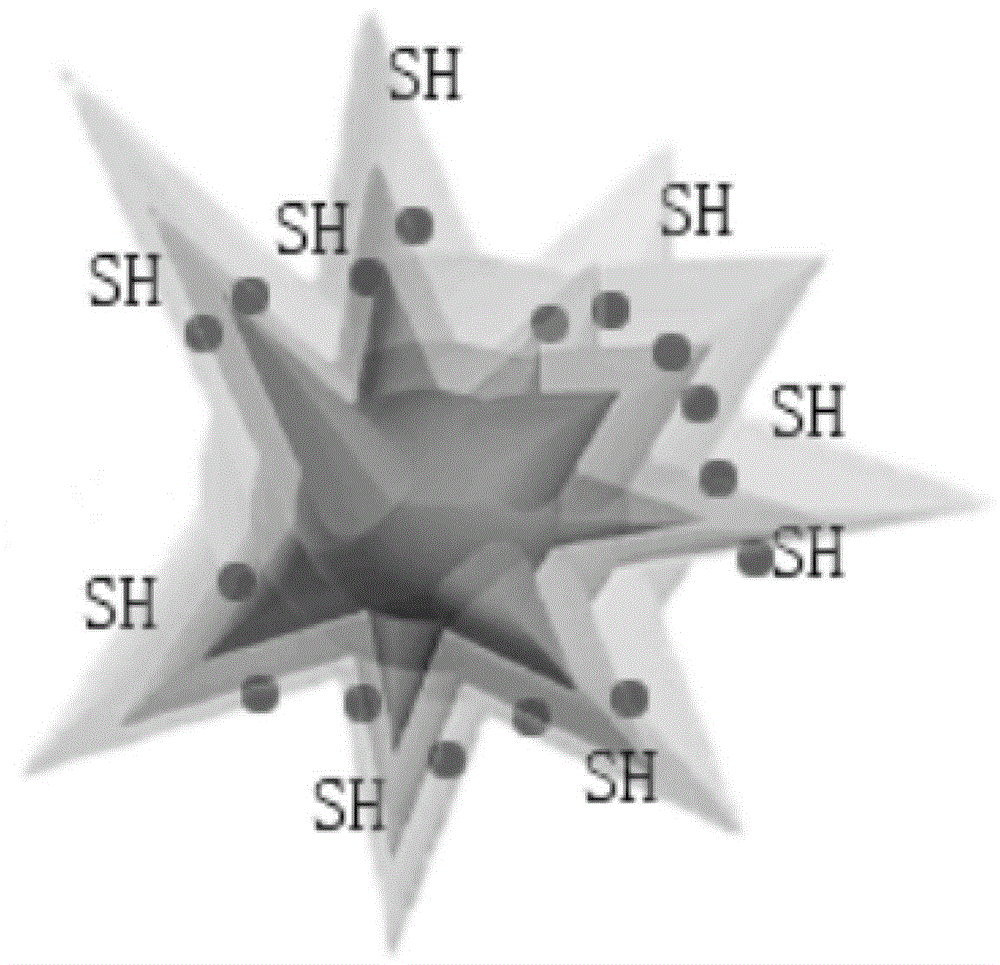

[0041] (1) Preparation of gold nanostars:

[0042] Dissolve 1-10ml of 1mM HAuCl 4 After the solution is boiled, add 0.1-5ml of 1% sodium citrate (or sodium borohydride, ascorbic acid, tetrakishydroxymethyl phosphorus chloride) solution to it, and heat (at a temperature of 25-100 degrees) to react 5- 400 minutes to obtain the size of the 5-200nm gold seed crystal solution; to 5-100mL of 1mM HAuCl 4 Add 10-5000uL of the above gold seed crystal solution (mixed with 50uL HCl solution) and stir for 5 minutes, then add 20-4000uL of 2M AgNO 3 The solution was stirred for 30s, and then centrifuged for later use; the size of the prepared gold nanostars was adjustable from 20-400nm;

[0043] (2) Preparation of gold nanostar quantum dot composites:

[0044] Dissolve 4 mL of prepared gold nanostars in a mixed solution of ethanol and water (preferably, the amount of the mixed solution of ethanol and water is based on the ability to dissolve gold nanostars, wherein the ethanol: the volume ...

Embodiment 1

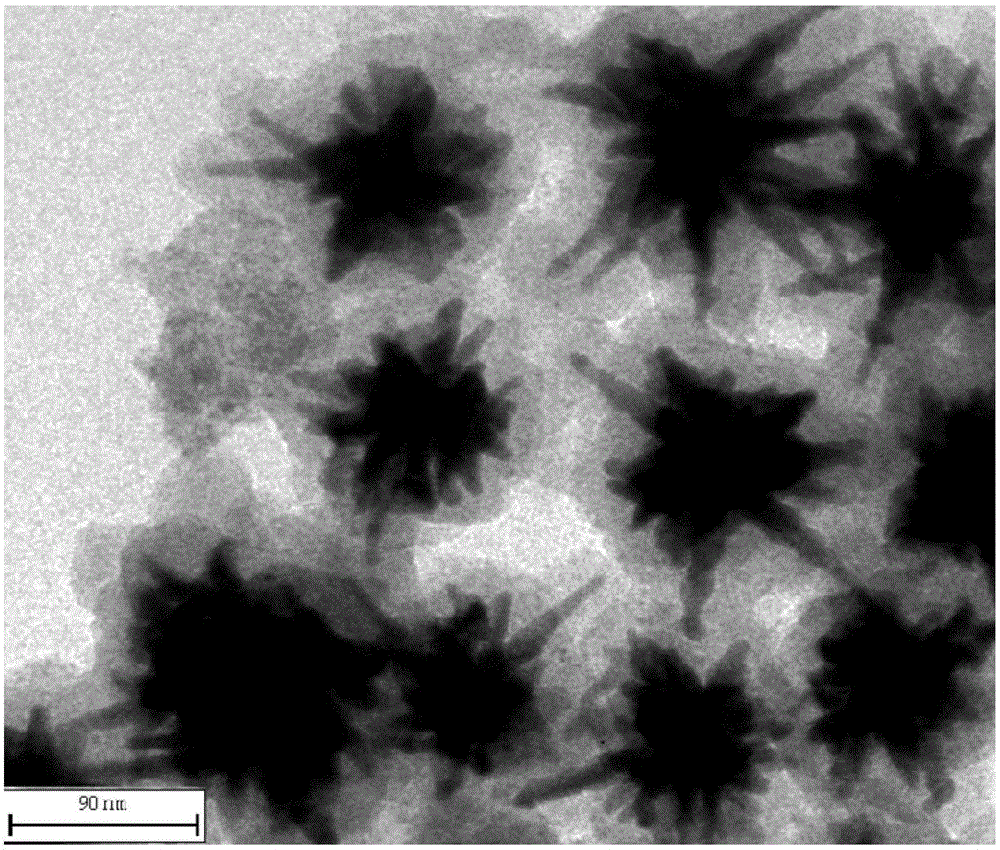

[0049] (1) Boil 4mL of 1mM HAuCl4 solution, add 0.7mL of 1% sodium citrate solution to it, heat at 80°C, and react for 15min to obtain a gold seed crystal solution. To 10 mL of 1 mM HAuCl 4 (mixed with 50uL HCl solution), add 100uL gold seed crystal solution and stir for 5 minutes, then add 100uL 2M AgNO 3 The solution was stirred for 30 s, and then centrifuged for later use.

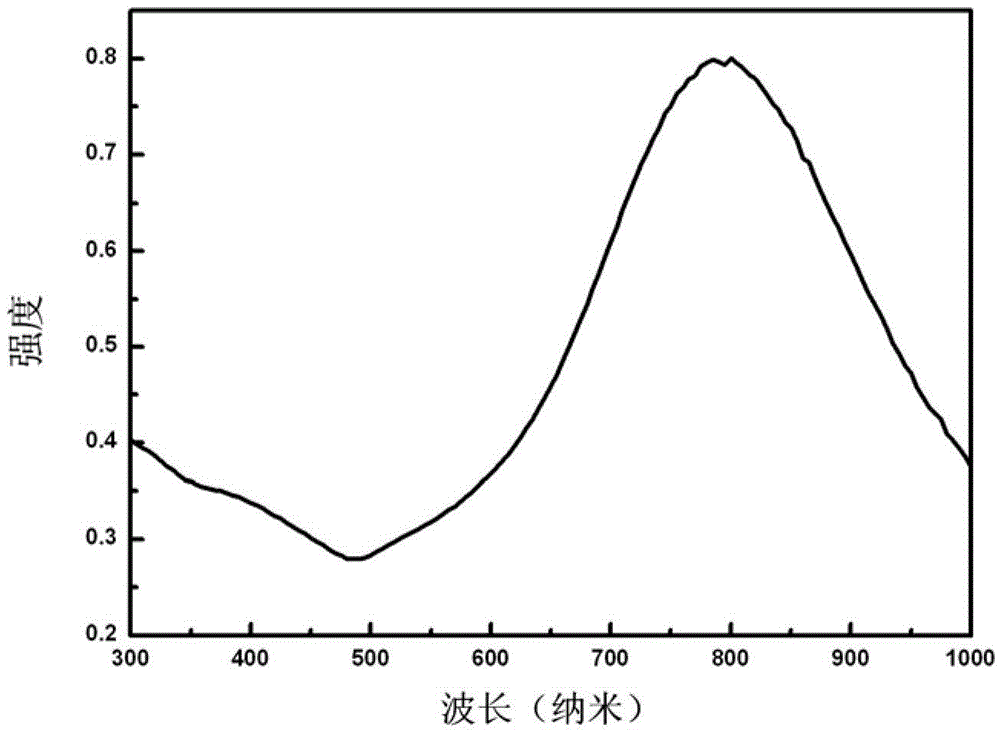

[0050] (2) Dissolve 4 mL of the prepared gold nanostars in a mixture of ethanol and water (preferably, the amount of the mixture of ethanol and water is subject to the ability to dissolve gold nanostars, wherein the ethanol: water The volume ratio is preferably 4:1), add 2mL of ammonia water, and then drop 300uL of tetraethyl orthosilicate (TEOS) into the reaction solution to coat the gold nanostars with silica spherical shells. After 24 hours of reaction Perform centrifugal washing; then 300uL of 3-aminopropyltrimethoxysiloxane (APTMS) was used to modify the surface of the silicon sphere, and then 3m...

Embodiment 2

[0053] (1) Add 4mL of 1mM HAuCl 4 After the solution was boiled, 1.0mL of 1% sodium citrate solution was added to it, and the gold seed crystal solution was obtained after reacting at 60°C for 15 minutes. To 10 mL of 1 mM HAuCl 4 (mixed with 50uL HCl solution), add 200uL gold seed crystal solution and stir for 5 minutes, then add 100uL 2M AgNO 3 The solution was stirred for 30 s, and then centrifuged for later use.

[0054] (2) Dissolve 4 mL of the prepared gold nanostars in a mixture of ethanol and water (preferably, the amount of the mixture of ethanol and water is subject to the ability to dissolve gold nanostars, wherein the ethanol: water The volume ratio is preferably 4:1), add 2mL of ammonia water, and then add 600uL of tetraethyl orthosilicate (TEOS) dropwise into the reaction solution to coat the gold nanostars with silica spherical shells. After 24 hours of reaction Perform centrifugal washing; then 600uL of 3-aminopropyltrimethoxysiloxane (APTMS) was used to modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com