Preparation method of polyester resin

A technology of polyester resin and polymerization degree, which is applied in the field of polyester resin preparation, can solve the problems of high cost of powder coating, influence on popularization and use, and high price of epoxy resin, achieve good gloss, reduce waste pollution, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] step one:

[0019] First crush 1030Kg of polyester waste (PET) to a particle size of 2-3mm, then add it to the alcoholysis reactor, add 170Kg of neopentyl glycol (NPG), and 129Kg of 2-methyl-1,3-propanediol (MPO) , 1.4Kg alcoholysis catalyst monobutyltin oxide (MBTO) and 1Kg zinc acetate for alcoholysis, the alcoholysis temperature is 220°C-250°C, when the temperature at the top of the tower drops to 80±5°C, the alcoholysis ends and is removed by filtration impurities;

[0020] Step two:

[0021] Add the melt obtained by filtering in step 1 into the esterification reactor, add 270Kg of purified terephthalic acid (PTA), and 0.8Kg of stabilizer triphenyl phosphite (TPP); carry out transesterification at 235°C to 250°C And esterification reaction, when the temperature at the top of the tower drops to 80±5°C (the water generated by the reaction does not distill out under normal pressure), take a sample, test the acid value and viscosity at 150°C, when the acid value is 28...

Embodiment 2

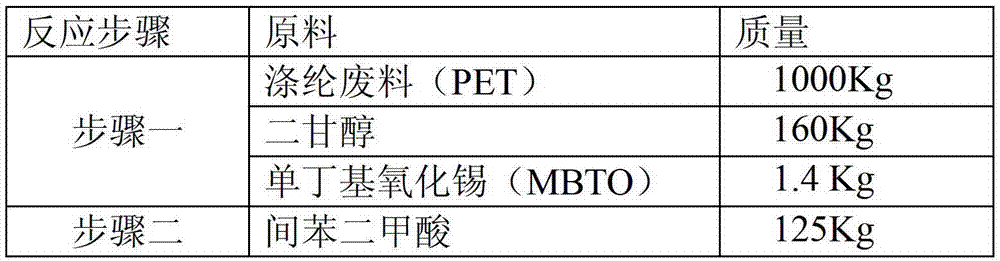

[0026] Reaction step is similar to embodiment 1, and reaction raw material and adding quality are as follows:

[0027]

[0028]

[0029] The performance test of the obtained product: the gloss is 95° tested by the gloss meter, and the paint film impact meter impacts the board surface, and there is no crack in the front impact of 50KG and recoil of 45KG.

Embodiment 3

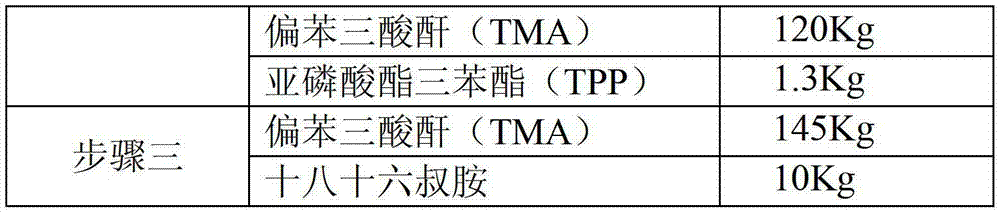

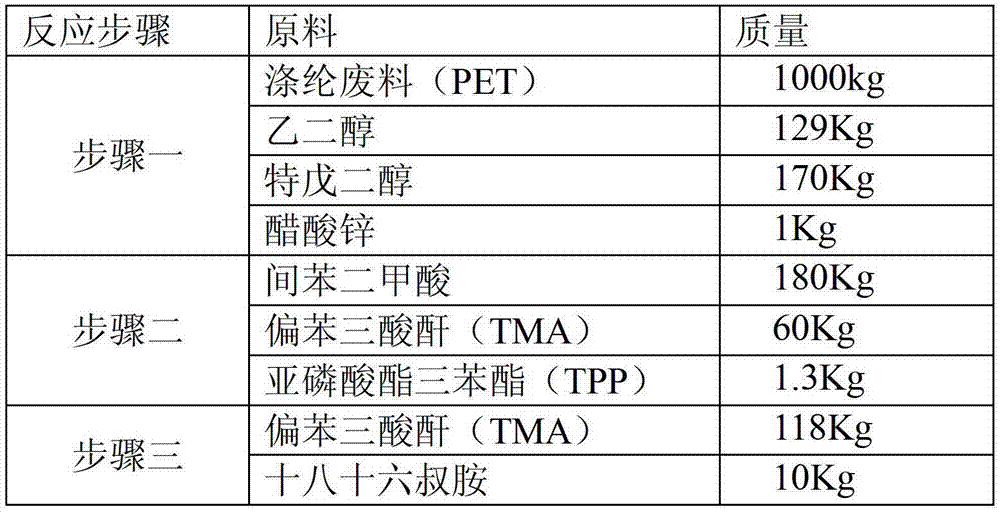

[0031] Reaction step is similar to embodiment 1, and reaction raw material and adding quality are as follows:

[0032]

[0033] The performance test of the obtained product: the gloss is 85° tested by a gloss meter, and the paint film impact meter impacts the board surface, and there is no crack in the front impact of 50KG and recoil of 45KG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com