Foaming agent for PVC foamed plastic

A foamed plastic and foaming agent technology, applied in the field of foaming agents, can solve the problems affecting the performance of plastic products, low technical quality level, low foaming ratio, etc., and achieves no suddenness in outgassing and easy control of processing conditions. , the effect of large air release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

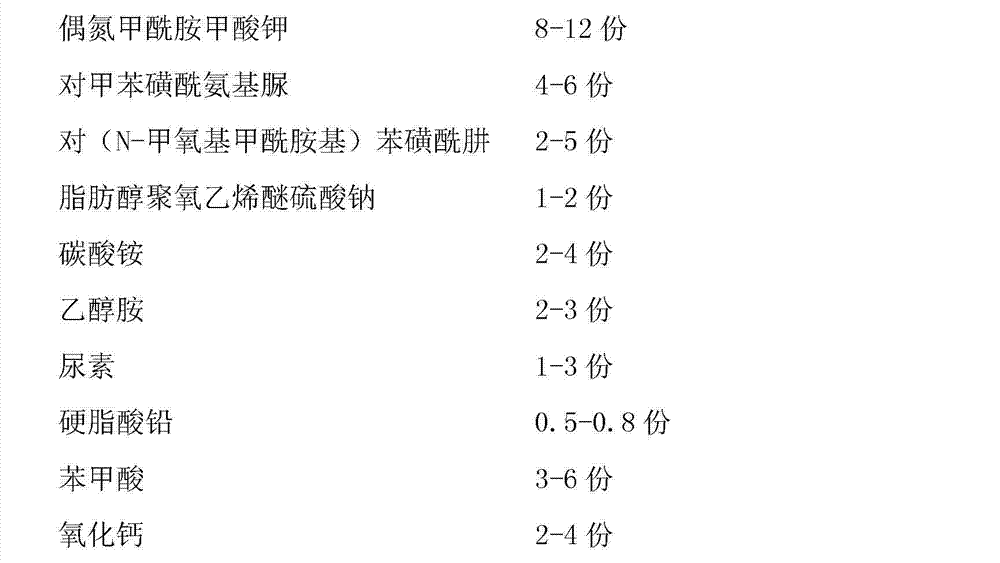

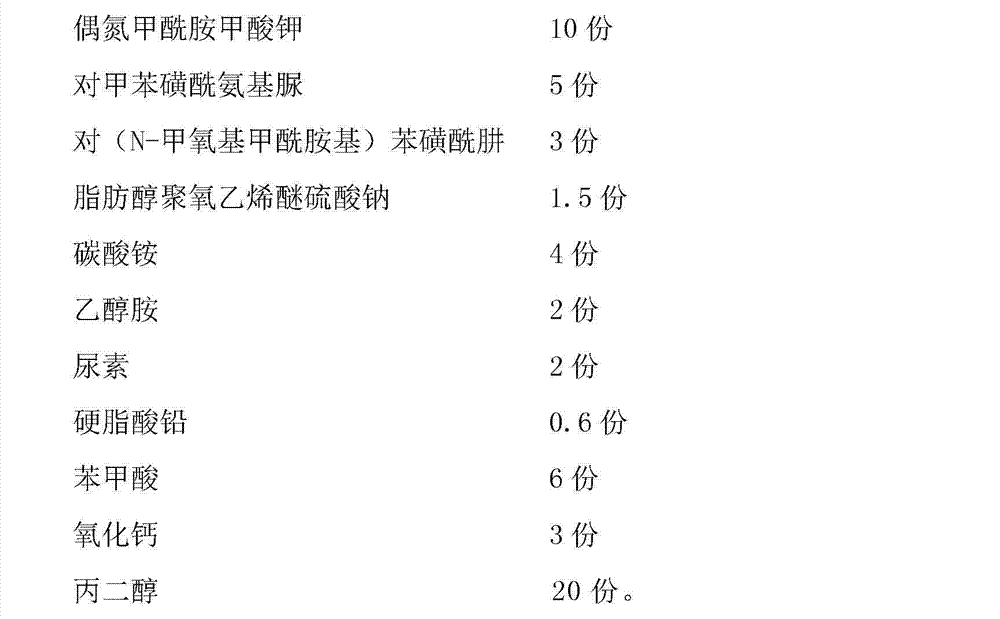

[0014] A blowing agent for PVC foam plastics, consisting of the following raw materials in parts by weight:

[0015]

[0016]

[0017] The composite foaming agent of the present invention is a novel foaming agent with excellent comprehensive performance. In order to verify the above results, a comparative experimental study was carried out, using pure azodicarbonamide and the composite foaming agent of the present invention as foaming agents to study their influence on the performance of PVC foam materials. The test results are shown in Table 1.

[0018] Table 1

[0019]

[0020] It can be seen from Table 1 that for a single foaming agent, the foamed material prepared by using a composite foaming agent has a lower density, a larger foaming rate, no burning phenomenon inside, and the tensile strength, compressive strength, and hardness are all higher than those obtained by using a composite foaming agent. The foamed material produced by a single blowing agent is much ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com