Organic/inorganic compound fertilizer for improving phosphorus use efficiency and preparation method thereof

A technology of compound fertilizer and utilization rate, applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problems such as no specific technical solutions are given, and achieve the effect of enhancing mobility, improving soil aggregate structure, and improving water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

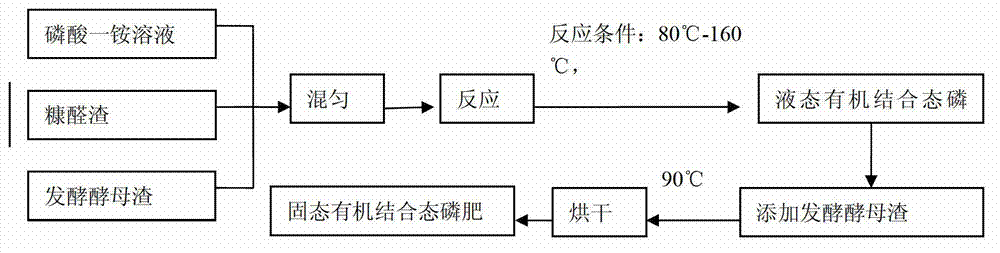

[0024] Embodiment 1: the preparation of organic binding state phosphate fertilizer

[0025] according to figure 1 process. Take 40kg of monoammonium phosphate and dissolve it in 100kg of water until it is completely dissolved. Take 3.0kg of furfural residue and 3.0kg of fermented yeast residue, combine and mix, add 18kg of monoammonium phosphate solution, place in a reaction kettle, and react at a constant temperature for 40min at 150°C until the yellow solid powder is completely melted. Add fermented yeast slag (purchased by Hubei Yichang Huifeng Fertilizer Co., Ltd., product index: organic matter ≥ 50%, moisture ≤ 30%) to the obtained liquid organic combined phosphate fertilizer at a ratio of 1:1 by weight, and fully Stir evenly, dry at 80°C until the water content is 18%, and obtain a solid organic-bound phosphate fertilizer. After testing, the content of available phosphorus is 22.7%.

Embodiment 2

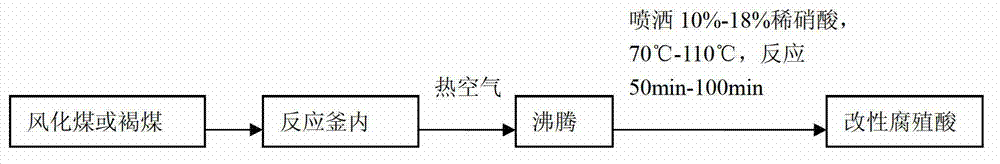

[0026] Embodiment 2: the preparation of modified humic acid

[0027] according to figure 2 According to the process, the weathered coal with an organic matter content (on a dry basis) of 75% is placed in a fluidized bed reactor, the weathered coal or lignite is boiled with hot air, and 15wt% dilute nitric acid is sprayed at a ratio of weathered coal: dilute Nitric acid=1:0.6, react at a temperature of 90°C for 80 minutes.

Embodiment 3

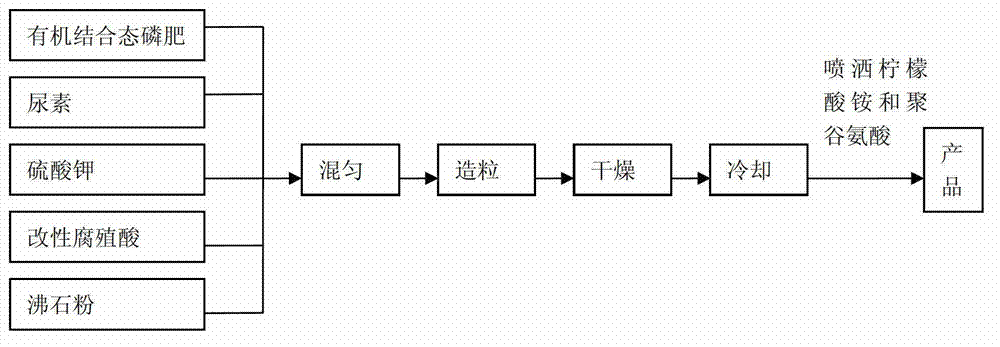

[0028] Embodiment 3: the preparation of the organic-inorganic compound fertilizer that improves phosphorus utilization rate

[0029] For the preparation process, see image 3 .

[0030] (1) Dissolve 40kg of monoammonium phosphate in 100kg of water until completely dissolved. Take 3.0kg of furfural residue and 3.0kg of fermented yeast residue, combine and mix, add 18kg of monoammonium phosphate solution, place in a reaction kettle, and react at a constant temperature for 60min at 140°C until the yellow solid powder is completely melted. Available phosphorus (P 2 o 5 ) content is the highest, reaching 12.2%. Add fermented yeast slag to the obtained liquid at a ratio of 1:1 by weight, stir well and evenly, dry at 90°C until the water content is 17%, and obtain a solid organic bound phosphate fertilizer. After testing, the content of available phosphorus was 25.7%.

[0031] (2) Put lignite with an organic matter content (calculated on a dry basis) of 79% in a fluidized bed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com