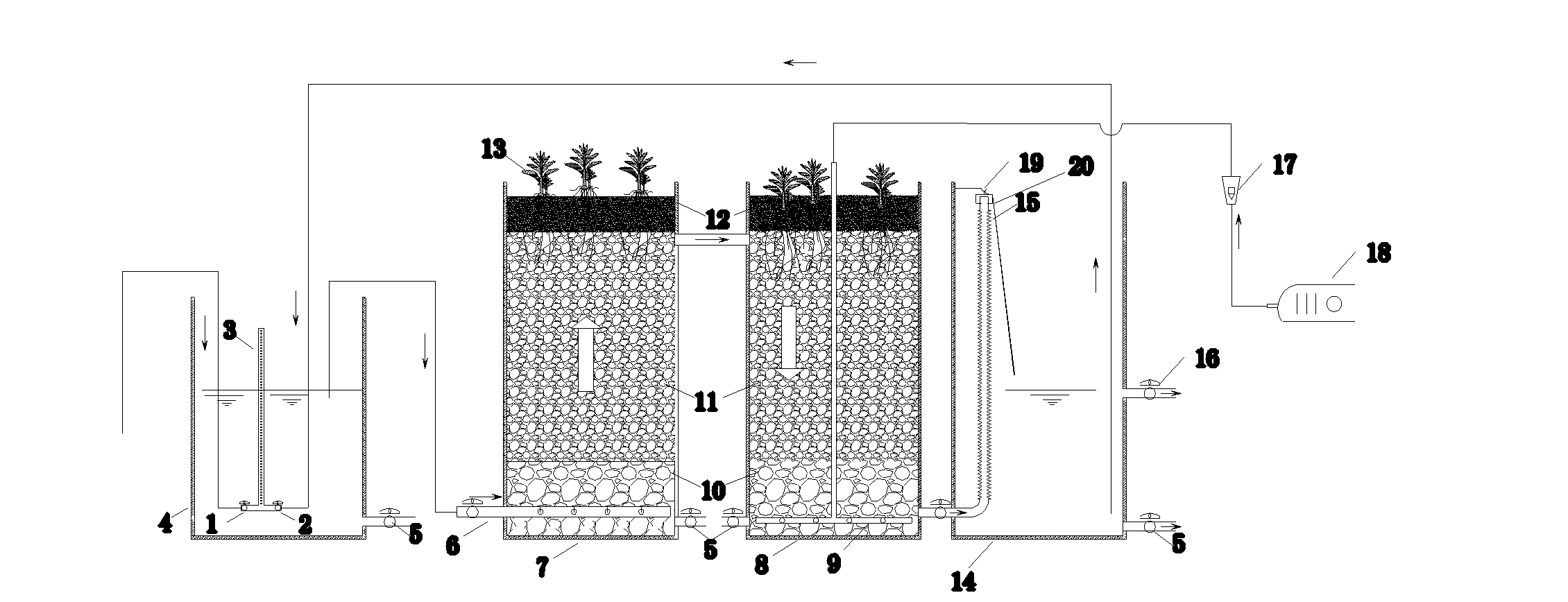

Vertical undercurrent artificial wetland system capable of reinforcing removal of total nitrogen without obstruction

A constructed wetland system and vertical subsurface flow technology, applied in the field of vertical flow constructed wetland sewage treatment technology, can solve the problems of complex process pipelines, difficult management, large floor area, etc., to improve the application range, reduce investment costs and operating costs , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0041]In the vertical subsurface constructed wetland system with no clogging and enhanced total nitrogen removal proposed by the present invention, the sewage is pretreated by a grille to remove most of the sundries and some suspended solids, and enters the constructed wetland system through the water inlet 1 . The sewage passes through the filter column 3 to remove most of the suspended solids and part of the organic matter, enters the bottom layer of the upstream wetland 7 through the water distribution system 6, and passes through the second gravel area 10, the first gravel area 11, and the peat soil 12 in turn. After that, it enters the downstream wetland 8, passes through the peat soil 12, the first crushed stone area 11, and the second crushed stone area 10, and the water from the bottom of the downstream wetland 8 enters the water collecting tank th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com