Molding and casting method for automobile cylinder cover with high air-tightness

A pouring method, the technology of the automobile cylinder, applied in the direction of casting mold composition, casting molding equipment, casting mold, etc., can solve the problems of little effect and achieve the effect of simple formula, increased air tightness and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

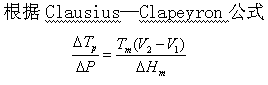

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention: the forming pouring method of the high-airtight automobile cylinder head, prepare the composite covering agent for standby (composition and usage method of the composite covering agent all adopt the technology disclosed in the authorized invention patent with application number 201010172549.0 content), after melting the charge of the cylinder head, add composite covering agent I to the furnace, heat up to the temperature required by the process, remove slag and discharge water, then add composite covering agent II, and then pour; adopt lost foam casting process , while pouring the molten metal formed by melting the furnace charge of the cylinder head into the lost foam, mechanically vibrate the molten metal until the molten metal is completely solidified; Vibration motor, the vibration frequency of the motor is 50HZ, the amplitude is 1mm, and the exciting force is 1.5KN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com