A kind of negative electrode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting the use surface of lithium-ion batteries and hindering the better development of lithium-ion batteries, and achieves suppression of irreversible side reactions and good structure. Effects of stability and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

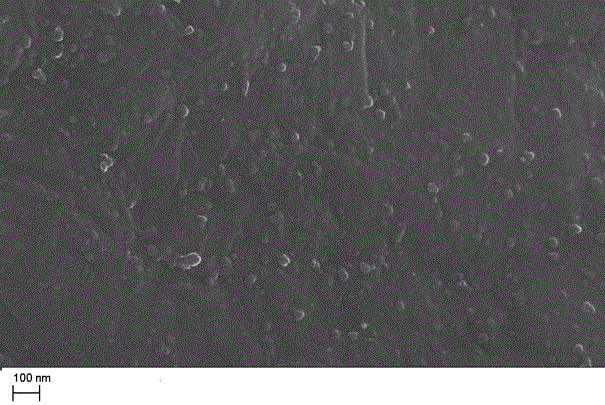

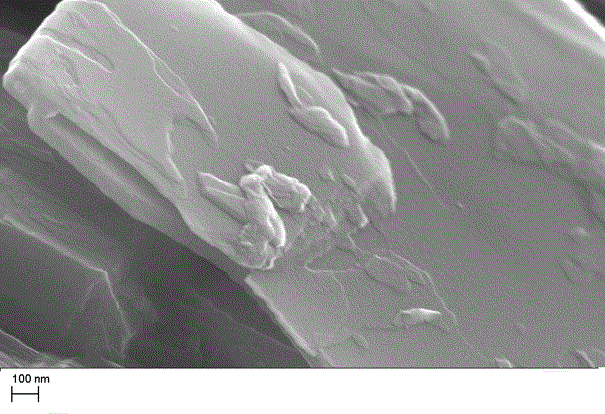

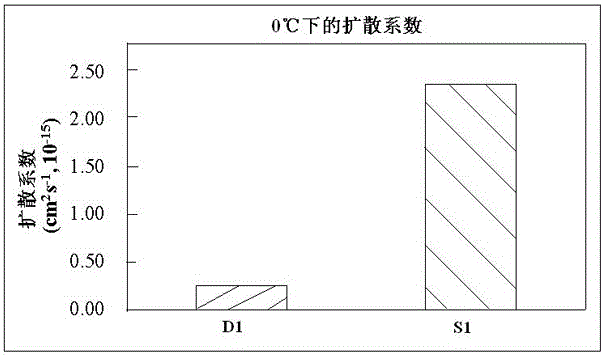

[0030] A negative electrode material for a lithium ion battery provided in this embodiment, the negative electrode material is a core-shell structure, including a shell layer and a core layer, the shell layer material is pyrolysis carbon, the core layer material is natural graphite, and the inside of the core layer material is filled There is coke; the internal pore diameter of the negative electrode material is 5-50nm, the average pore diameter is 17nm, and the pore volume is 0.066cm 3 / g, the powder compaction density of negative electrode material under 1000 kg pressure is 1.50g / cm 3 , The specific surface area is 2. 3m 2 / g; tap density is 1.1g / cm 3 and the intensity ratio (C004 / C110) of the X-ray diffraction peak intensity of the 004 crystal plane of the negative electrode material to the X-ray diffraction peak of the 110 crystal plane is 6.0 (the test method is: the negative electrode material provided by the present embodiment and superconducting carbon After mixing w...

Embodiment 2

[0032]A negative electrode material for a lithium ion battery provided in this embodiment, the negative electrode material is a core-shell structure, including a shell layer and a core layer, the shell layer material is pyrolysis carbon, the core layer material is natural graphite, and the inside of the core layer material is filled With coke; the internal pore diameter of the negative electrode material is 0.1-200nm, the average pore diameter is 5nm, and the pore volume is 0.06cm 3 / g, the powder compaction density of negative electrode material under 1000 kg pressure is 1.40g / cm 3 , the specific surface area is 2.0m 2 / g; tap density is 1.5g / cm 3 and the intensity ratio (C004 / C110) of the X-ray diffraction peak intensity of the 004 crystal plane of the negative electrode material to the X-ray diffraction peak of the 110 crystal plane is 3.0 (the test method is: the negative electrode material provided by the present embodiment and superconducting carbon After mixing with s...

Embodiment 3

[0034] A negative electrode material for a lithium ion battery provided in this embodiment, the negative electrode material is a core-shell structure, including a shell layer and a core layer, the shell layer material is pyrolysis carbon, the core layer material is natural graphite, and the inside of the core layer material is filled With coke; the internal pore diameter of the negative electrode material is 5-100nm, the average pore diameter is 20nm, and the pore volume is 0.08cm 3 / g, the powder compaction density of negative electrode material under 1000 kg pressure is 1.60g / cm 3 , with a specific surface area of 3m 2 / g; tap density is 0.9g / cm 3 and the intensity ratio (C004 / C110) of the X-ray diffraction peak intensity of the 004 crystal plane of the negative electrode material to the X-ray diffraction peak of the 110 crystal plane is 10.0 (the test method is: the negative electrode material provided by the present embodiment and superconducting carbon After mixing wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com