Surface-modified lithium titanate and preparation method thereof

A technology of surface modification and lithium titanate, which is applied in the field of lithium-ion batteries, can solve problems such as incomplete coating, and achieve the effects of reducing catalytic activity, good repeatability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

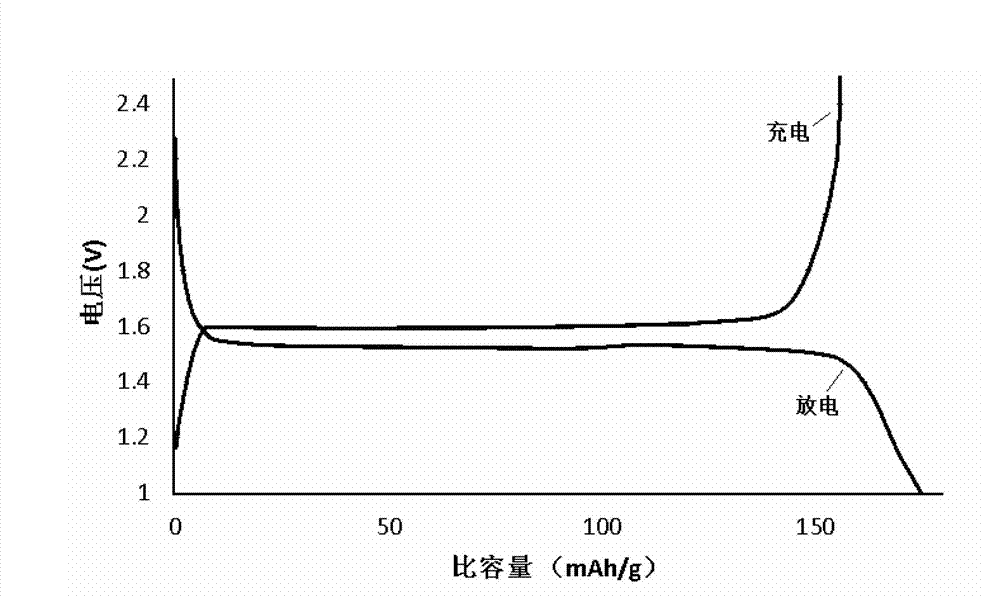

Image

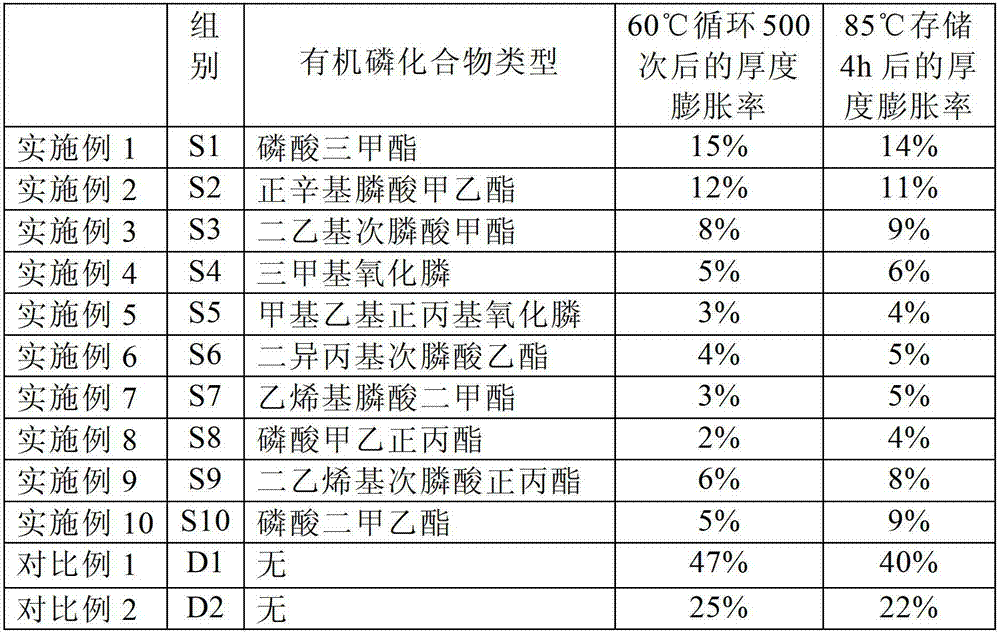

Examples

preparation example Construction

[0021] The method for preparing surface-modified lithium titanate according to the second aspect of the present invention is used to prepare the surface-modified lithium titanate according to the first aspect of the present invention, comprising the step of: dissolving lithium titanate particles in the first inorganic water organic solvent to obtain a suspension; the organophosphorus compound is added to the suspension; after the reaction is completed, the suspension is subjected to suction filtration; the solid obtained after the suction filtration is treated with a second anhydrous organic solvent After washing and drying, the surface-modified lithium titanate is obtained; wherein, the organophosphorus compound is a phosphine oxide compound represented by the general formula (1) O=P-RR'R'', and is represented by the general formula (2) A phosphinate compound represented by O=P-(OR)R'R'', a phosphonate compound represented by the general formula (3) O=P-(OR)(OR')R'', or Phosp...

Embodiment 1

[0029] Add 50 g of lithium titanate particles with a particle size of 10 nm into 250 mL of absolute ethanol in a dry atmosphere, and then stir at a speed of 500 rpm for 30 min to obtain a uniformly dispersed suspension;

[0030] Add trimethyl phosphate (the mass ratio of trimethyl phosphate to lithium titanate is 0.01:100) under stirring conditions, and keep stirring for 3 hours after the addition is complete;

[0031] After the reaction is over, perform suction filtration on the suspension after the reaction, put the solid obtained after suction filtration into a beaker, add 100mL of absolute ethanol to wash, stir and disperse the solid, and then suction filter, repeat this three times, and dry Obtain the lithium titanate of surface passivation afterwards;

[0032]Among them, the lithium titanate surface is distributed with a structure formula of -O-P-(OCH 3 ) 3 The passivation group, between the passivation group and lithium titanate particles with Ti-O-P-(OCH 3 ) 3 bond...

Embodiment 2

[0034] Add 50 g of lithium titanate particles with a particle size of 50 nm into 250 mL of anhydrous methanol in a dry atmosphere, and then stir at a speed of 500 rpm for 30 min to obtain a uniformly dispersed suspension;

[0035] Add methyl ethyl n-octyl phosphonate (wherein the mass ratio of methyl ethyl n-octyl phosphonate to lithium titanate is 0.1:100) under stirring conditions, keep the rotation speed constant after the addition and continue stirring for 1 h;

[0036] After the reaction, the suspension after the reaction was subjected to suction filtration, the solid obtained after the suction filtration was placed in a beaker, 100 mL of anhydrous isopropanol was added for washing, the solid was stirred and dispersed, and then suction filtered, and so repeated three times, Obtain the lithium titanate of surface passivation after drying;

[0037] Among them, the lithium titanate surface is distributed with a structure formula of -O-P-(C 7 h 14 CH 3 )(OCH 2 CH 3 )(OCH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com