Method for measuring critical temperature of high temperature creep crack growth of material

A technology of crack propagation and critical temperature, which is used in measurement devices, analytical materials, thermal analysis of materials, etc., can solve the problem of high requirements for test equipment, and achieve the effect of reducing test costs, high costs, and shortening test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

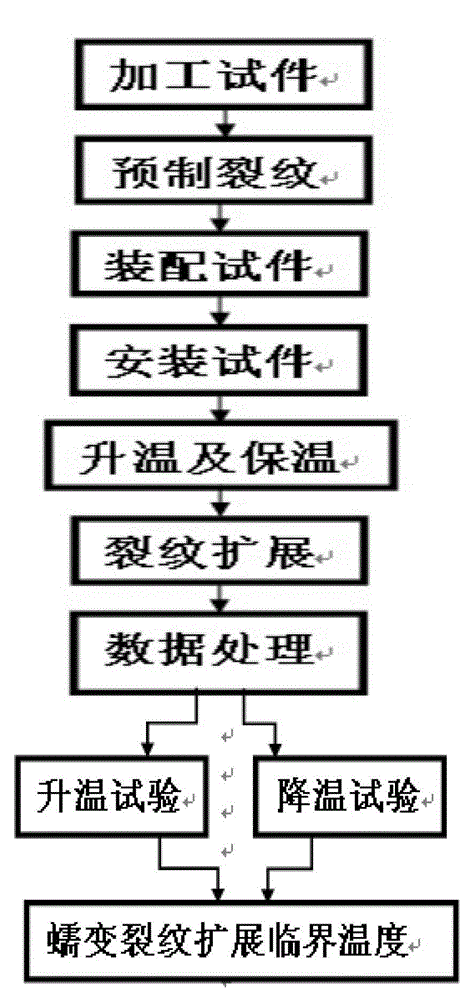

[0030] Such as figure 1 Shown, the specific implementation steps of the present invention are as follows:

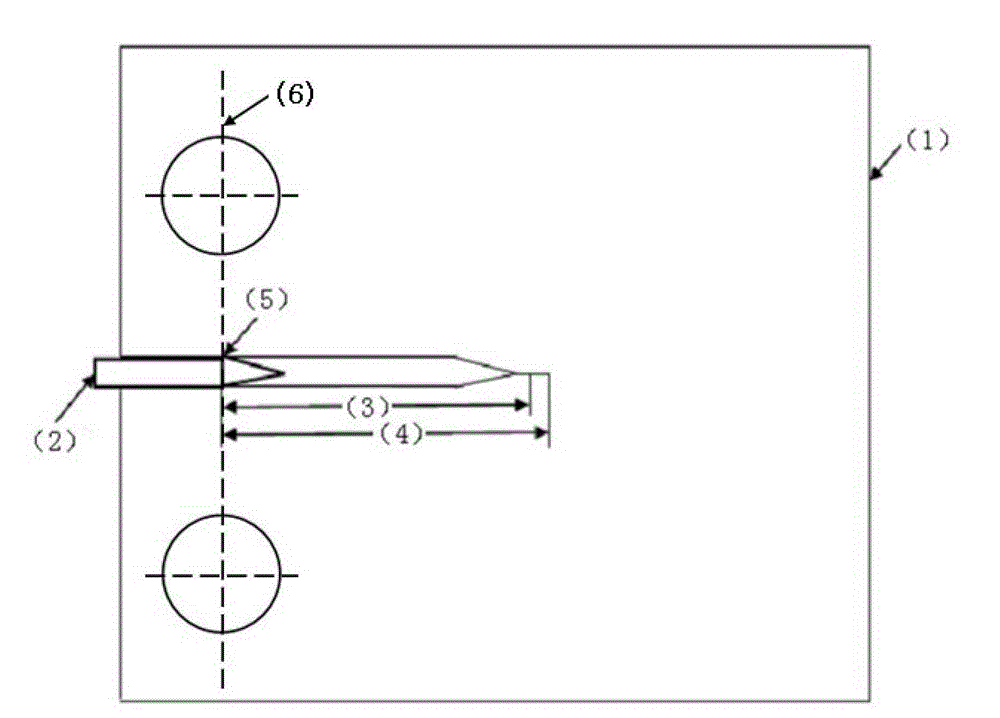

[0031] 1. Processing specimens: For the specific materials studied, process a batch (at least 6 pieces) of standard compact tension (CT) specimens according to the requirements of the creep crack growth test. The initial incision height is 2 mm; the initial incision length is 0.45 times the width of the test piece; the surface of the test piece is first polished with 300-grit sandpaper and then with 2000-grit fine sandpaper to make the surface roughness and finish as high as possible so that the crack propagation path can be observed. Process a batch (at least 6 pieces) of wedges with different thicknesses. The thickness of the wedges starts from 2.1mm. The thickness difference between the wedges is 0.05mm. The width of the wedges is consistent with the width of the test piece. The distance to the left side of the specimen is 2mm larger.

[0032] 2. Prefabricated crack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com