Smoke reflux vaporized alcohol-based fuel burner

An alcohol-based fuel and burner technology, which is applied to burners, combustion types, combustion methods, etc., can solve the problems of low heat utilization efficiency, easy carbon deposition, and insufficient combustion, so as to improve combustion efficiency and reduce tension. , Improve the effect of comprehensive heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

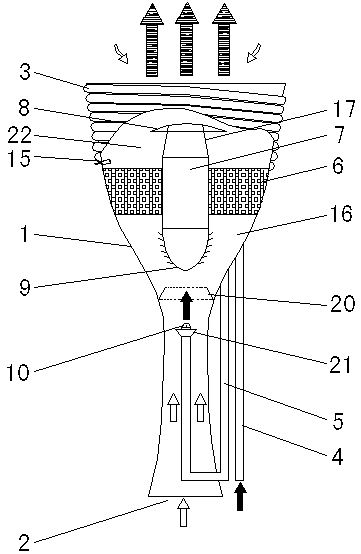

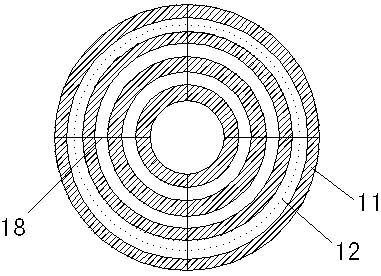

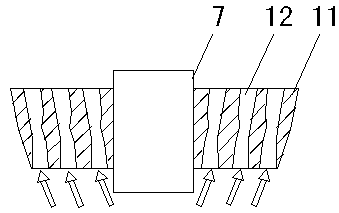

[0025] like Figure 1~4 As shown, the flue gas reflux vaporization alcohol-based fuel burner includes a hollow shell 1 with a wine glass shape. The shell 1 has a large diameter at both ends and a small diameter at the middle. The bottom end of the housing 1 is the air inlet 2, the top of the housing 1 is the smoke outlet, the top of the housing 1 is provided with a fuel pipeline 3 in a spiral structure along the inner wall, the upper port of the fuel pipeline 3 is connected with the fuel input pipe 4, and the fuel input pipe 4 extending vertically downward to the bottom of the casing 1, the lower port of the fuel pipeline 3 is connected with the fuel output pipe 5, the fuel output pipe 5 is in a U-shaped structure, and the outlet section of the fuel output pipe 5 extends vertically upward from the lower part of the casing 1 Towards t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com