Exhaust gas recirculation (EGR) control method and control system of diesel engine and based on excess air coefficient

A technology of excess air coefficient and control system, applied in the direction of engine control, mechanical equipment, machine/engine, etc., can solve the problems of deterioration of harmful pollutant emissions, inability to apply, and inability to truly reflect the state of cylinder mixture, and achieve closed-loop control. , The effect of realizing exhaust emission control and improving the effect of emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

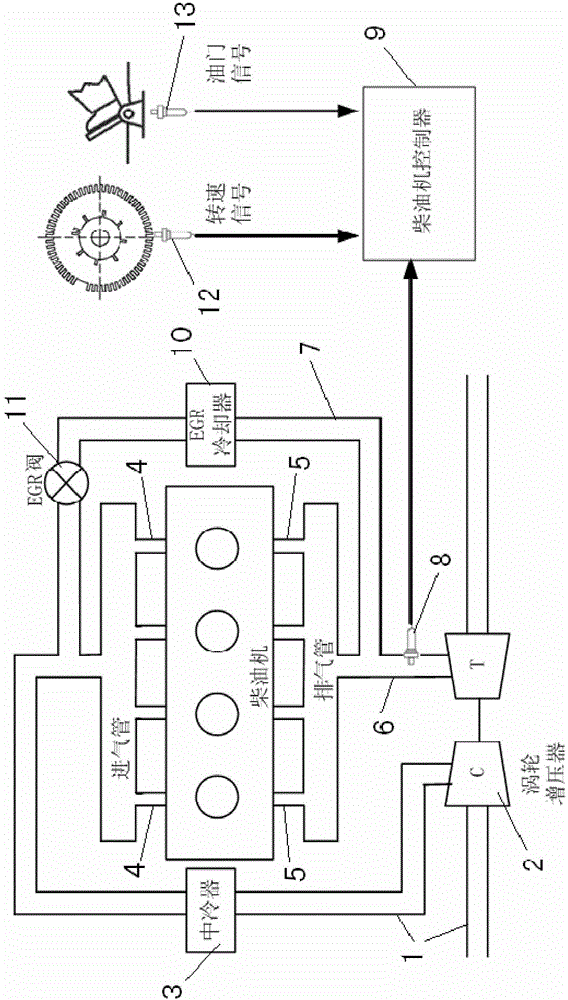

[0016] Such as figure 1 As shown, the diesel engine EGR control system of the present invention adopts a closed-loop control system, which includes an intake manifold 1, a turbocharger 2, an intercooler 3, an intake manifold 4 communicated with each cylinder inlet end of a diesel engine, and each cylinder Exhaust manifold 5, exhaust manifold 6, EGR circuit 7, wide area oxygen sensor (UEGO) 8, diesel engine controller 9, EGR cooler 10, EGR valve 11, speed sensor 12 and accelerator pedal position sensor connected to the outlet port 13.

[0017] The inlet end of the intake manifold 1 is provided with a turbocharger 2, the air outlet of the turbocharger 2 is connected to the intercooler 3 through the intake manifold 1, fresh air enters the intercooler 3 after being cooled by the turbocharger 2, It enters each cylinder of the diesel engine through each i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com