Method for Reducing Olefin Content in Crude Gasoline

A technology of olefin content and gasoline, which is applied in the field of reducing olefin content in crude gasoline, can solve the problems of reducing olefin content, large differences in solvent systems, and no teaching, etc., and achieve the effect of reducing olefin content and realizing effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

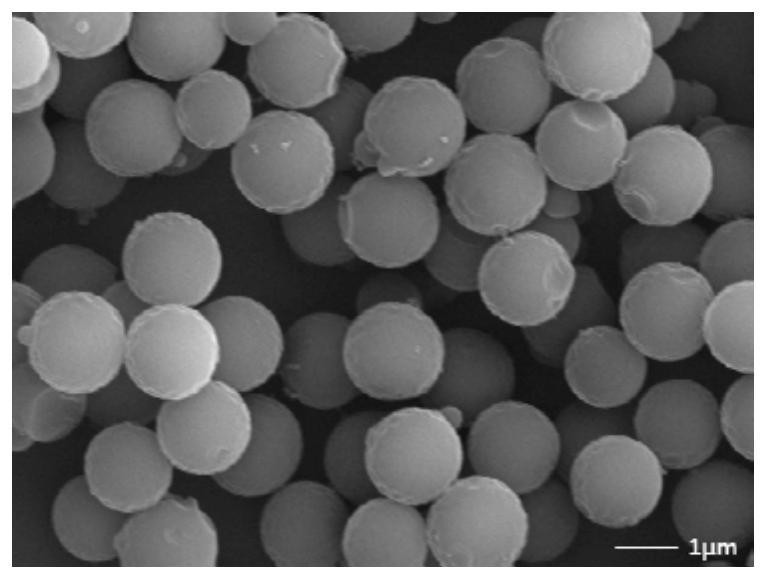

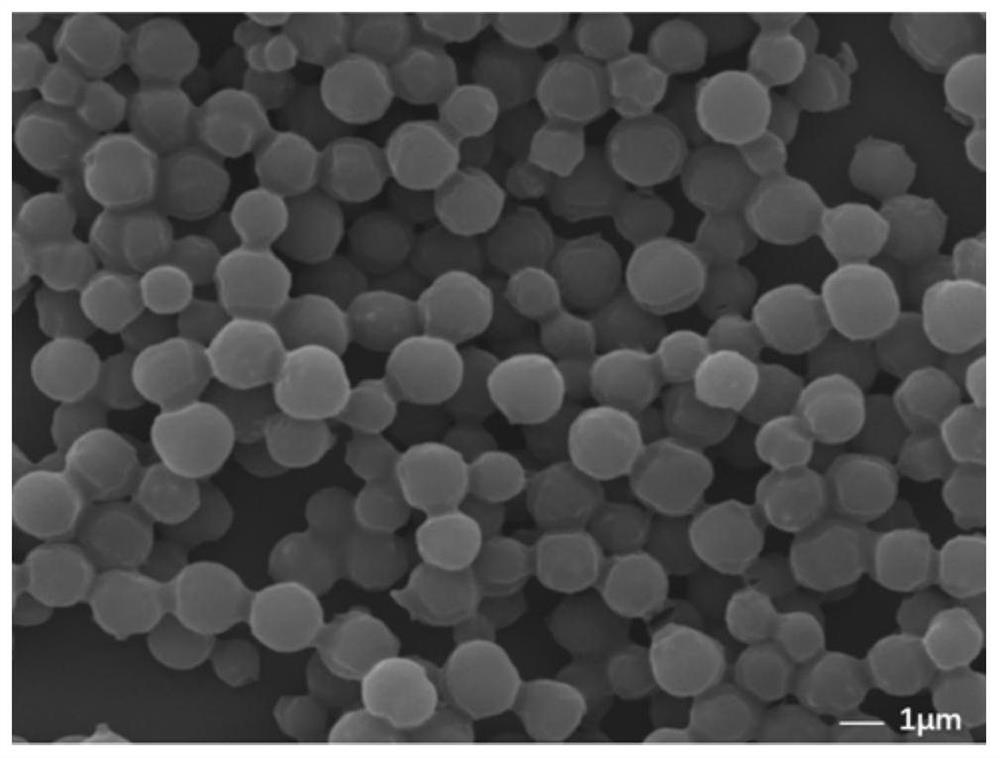

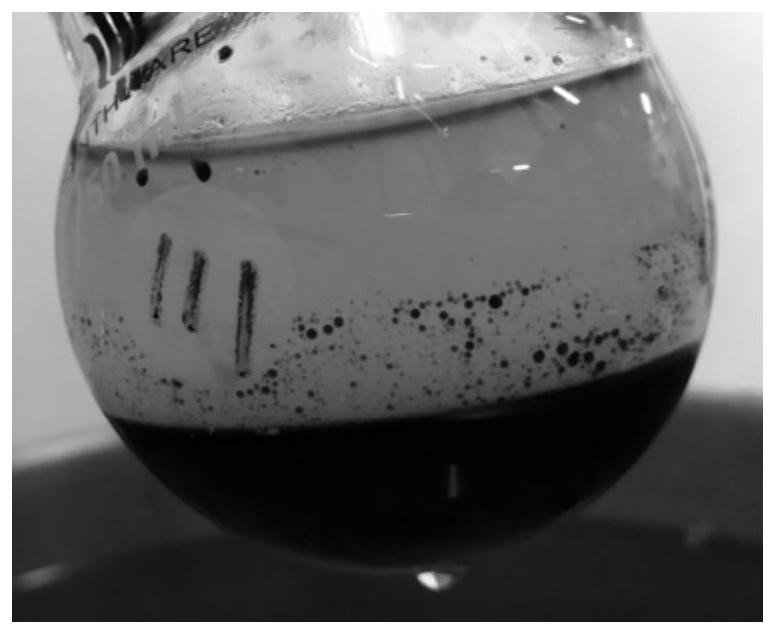

Image

Examples

Embodiment 1

[0084] Add 1.0g of maleic anhydride and 0.09g of AIBN as shown in the formula in Table 1 to the pre-ether gasoline; make the above-mentioned monomer maleic anhydride and the olefin in the pre-ether gasoline carry out copolymerization at 70°C for 10 hours, with the reaction progressing , a precipitate of a polymer product is produced in the system; the precipitate is separated by filtration, and the crude gasoline after the olefin reduction treatment can be obtained.

[0085] In order to evaluate the reduction degree of olefin content, the precipitate was alternately washed with toluene and petroleum ether to remove unreacted maleic anhydride and impurities, and the obtained polymer product was vacuum-dried to constant weight.

Embodiment 2

[0087] Add 1.5g of maleic anhydride, 0.105g of BPO, and 12g of xylene as shown in the formula in Table 1 to gasoline before ether; make the above-mentioned monomer maleic anhydride and olefins in gasoline before ether self-stabilize at 70°C Precipitation polymerization, reaction for 10 hours, as the reaction progresses, a precipitate of the polymer product is produced in the system; the precipitate is separated by filtration, and the filtrate is further fractionated, and the fraction before 80°C is collected to obtain the olefin-reduced crude gasoline.

[0088] In order to evaluate the reduction degree of olefin content, the precipitate was alternately washed with toluene and petroleum ether to remove unreacted maleic anhydride and impurities, and the obtained polymer product was vacuum-dried to constant weight.

Embodiment 3

[0090] Add 2g of maleic anhydride, 0.2g of ABVN and 20g of toluene as shown in the formula in Table 1 to gasoline before ether; make the above-mentioned monomer maleic anhydride and olefins in gasoline before ether undergo self-stable precipitation polymerization at 50°C, After 20 hours of reaction, as the reaction proceeds, a precipitate of a polymer product is produced in the system; the precipitate is separated by filtration, the filtrate is further fractionated, and the fraction before 80°C is collected to obtain crude gasoline after olefin reduction treatment .

[0091] In order to evaluate the reduction degree of olefin content, the precipitate was alternately washed with toluene and petroleum ether to remove unreacted maleic anhydride and impurities, and the obtained polymer product was vacuum-dried to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com