Arrangement for extracting extraction products in underground extraction operations in caving

A caving mining and product technology, applied in mining equipment, earth drilling, underground transportation, etc., can solve problems such as heavy work, danger, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

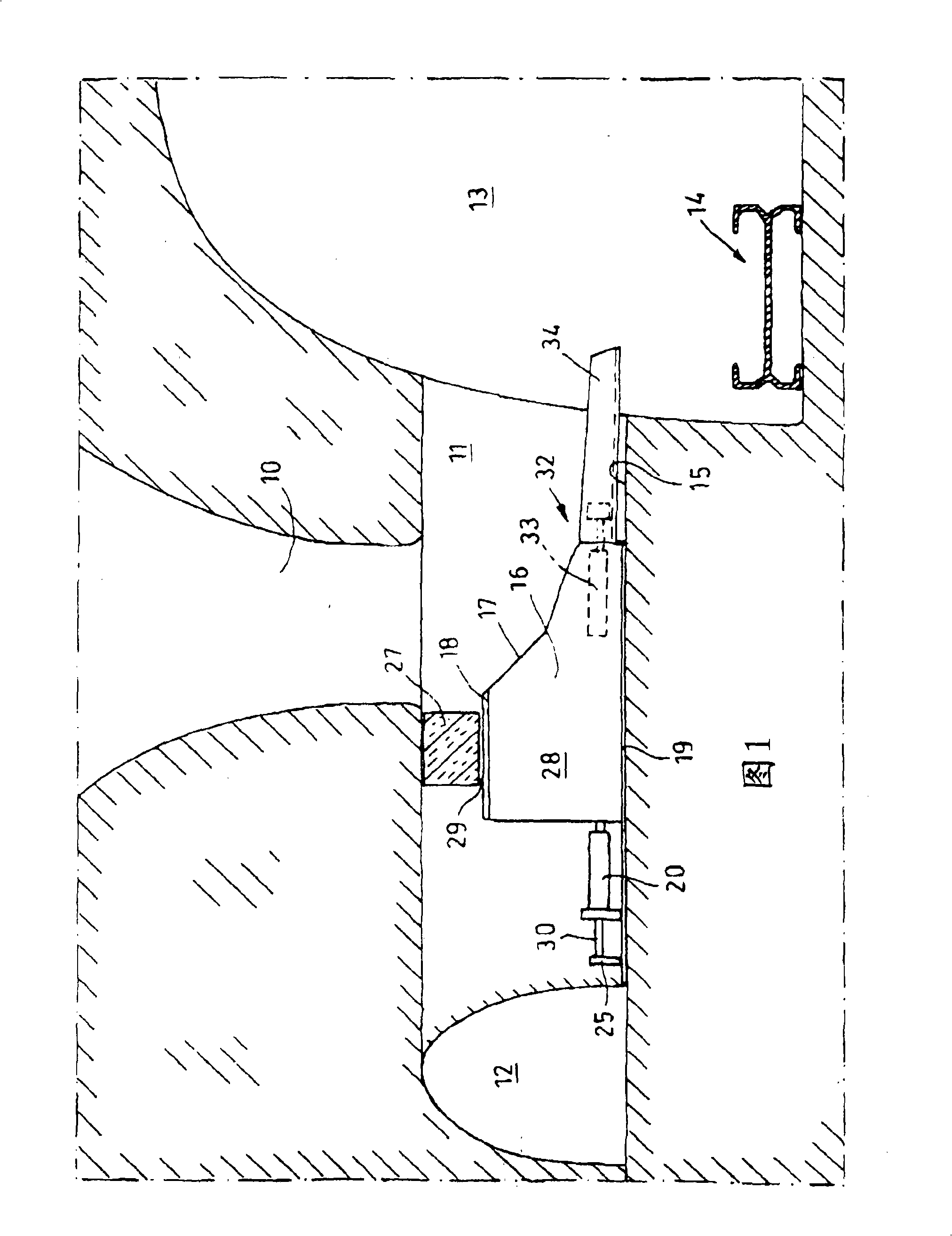

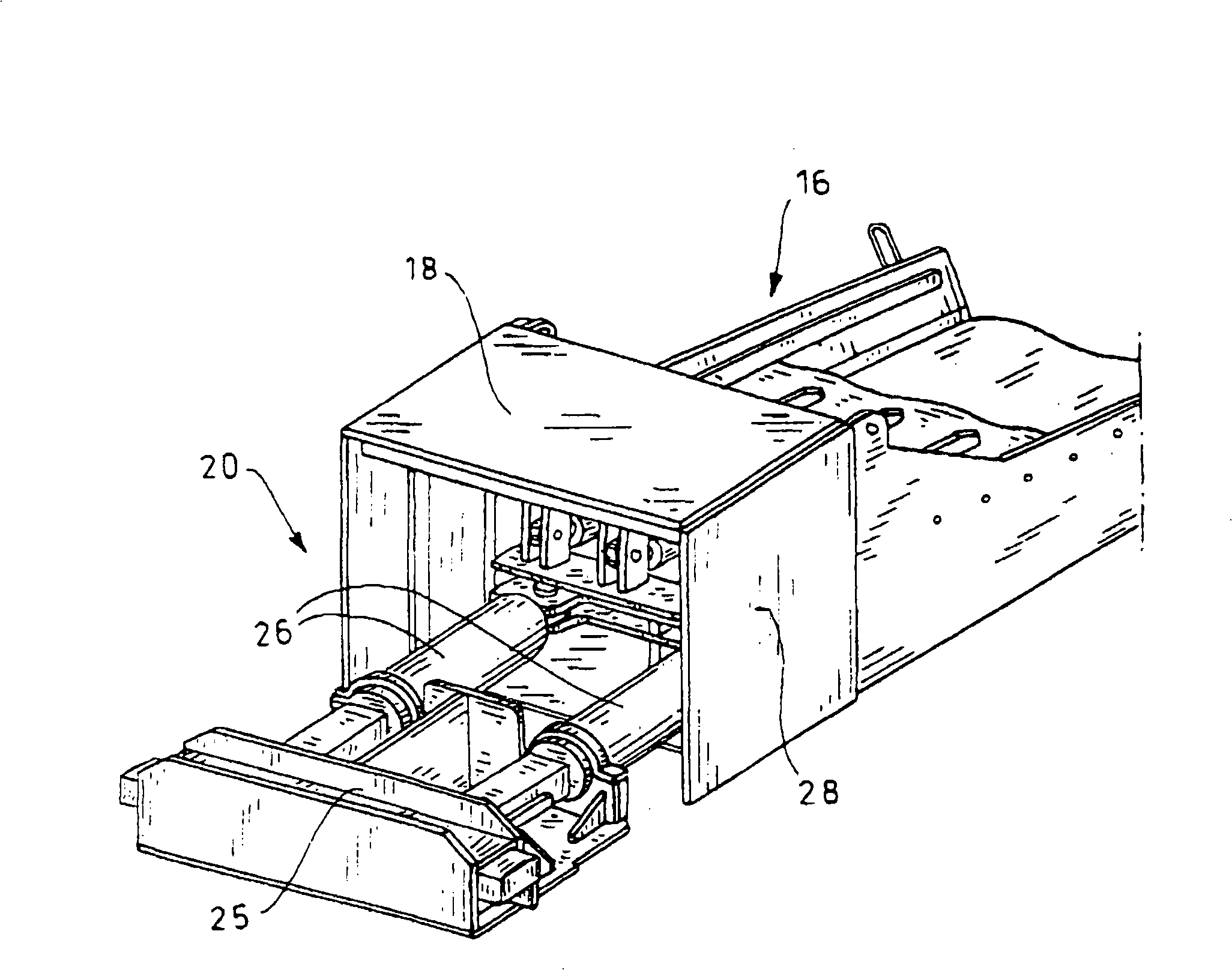

[0018] Copper ore is mined in the caving mining method with the device according to the invention, which caving in a (not shown) mining face arranged above the discharge hopper 10 and then discharges through the discharge hopper 10 into a below Unloading roadway 11. The discharge tunnel 11 extends transversely both to an auxiliary tunnel 12 and to a delivery tunnel 13 in which a chain-type scraper conveyor 14 is arranged for the removal of recovered products. The transversely extending discharge tunnel 11 is accessible to this from the side of the auxiliary tunnel 12 . The floor of the conveyor tunnel 13 and the chain scraper conveyor arranged thereon are at a lower level than the floor 15 of the discharge tunnel, so that the discharge tunnel 11 leads to the conveyor tunnel above the conveyor and the recovered product can be extracted from The top falls onto the conveyor.

[0019] In order to feed the recovered product discharged from the discharge hopper and sent to the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com