Nickel nanorod-nickel oxide nanosheet hierarchical structure array modified with silver nanoparticles and preparation method and application thereof

A technology of nickel oxide nanosheets and silver nanoparticles, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not being able to obtain SERS active nickel nanostructure substrates, and achieve regular morphology , Improve SERS activity, the effect of high SERS activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

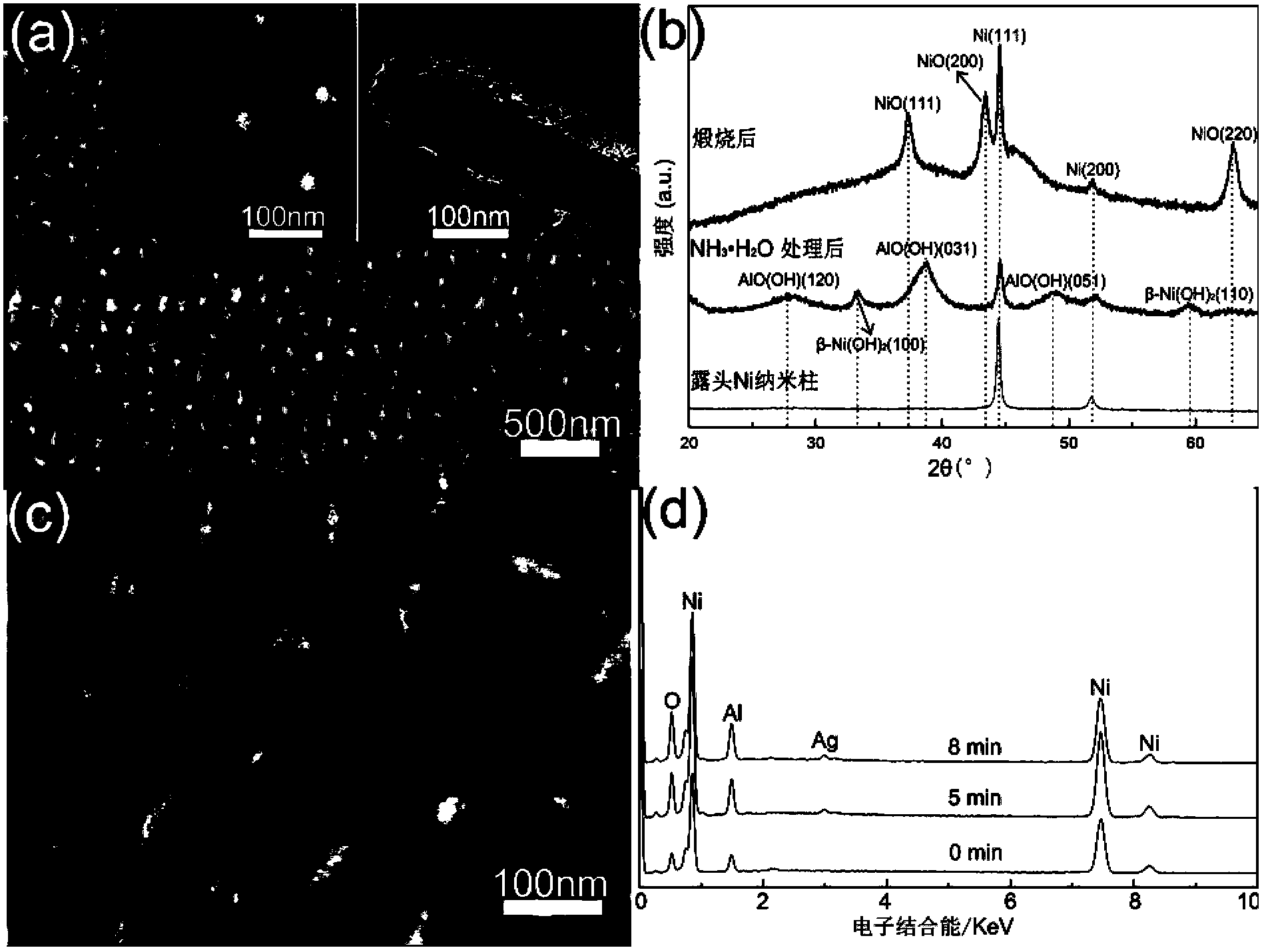

[0032] The concrete steps of preparation are:

[0033] In step 1, the aluminum sheet is firstly treated with a secondary anodic oxidation method and a hole expansion method to obtain a through-hole alumina template with a hole diameter of 90 nm and a hole spacing of 20 nm. Then use a magnetron sputtering apparatus to sputter the silver film on one side of the through-hole alumina template; during sputtering, the distance between the alumina template and the silver target is 2cm, the sputtering current is 40mA, and the sputtering time is 10min. Alumina template coated with silver film on one side.

[0034] In step 2, the aluminum oxide template covered with a silver film on one side is used as the cathode, and the graphite is used as the anode, placed in the nickel electrolyte, and electrodeposited at a DC voltage of 1.5V for 2 hours to obtain a nickel nanopillar array in the hole. Alumina template coated with silver film on one side. Place the aluminum oxide template covered...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] In step 1, the aluminum sheet is firstly treated with a secondary anodic oxidation method and a hole expansion method to obtain a through-hole alumina template with a hole diameter of 93nm and a hole spacing of 23nm. Then use a magnetron sputtering apparatus to sputter the silver film on one side of the through-hole alumina template; during sputtering, the distance between the alumina template and the silver target is 2cm, the sputtering current is 40mA, and the sputtering time is 10min. Alumina template coated with silver film on one side.

[0040] Step 2. First, the aluminum oxide template covered with a silver film is used as the cathode and the graphite as the anode, placed in the nickel electrolyte, and electrodeposited at a DC voltage of 1.75V for 1.8h to obtain an array of nickel nanopillars in the holes. Alumina template coated with silver film on one side. Place the aluminum oxide template covered with silver fi...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] In step 1, the aluminum sheet is firstly treated with a secondary anodic oxidation method and a hole expansion method to obtain a through-hole alumina template with a hole diameter of 95 nm and a hole spacing of 25 nm. Then use a magnetron sputtering apparatus to sputter the silver film on one side of the through-hole alumina template; during sputtering, the distance between the alumina template and the silver target is 2cm, the sputtering current is 40mA, and the sputtering time is 10min. Alumina template coated with silver film on one side.

[0046] In step 2, the aluminum oxide template covered with a silver film is used as the cathode and the graphite as the anode, placed in the nickel electrolyte, and electrodeposited at a DC voltage of 2V for 1.5h to obtain a nickel nanopillar array in the hole. Alumina template coated with silver film on one side. Place the aluminum oxide template covered with the silver film on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com