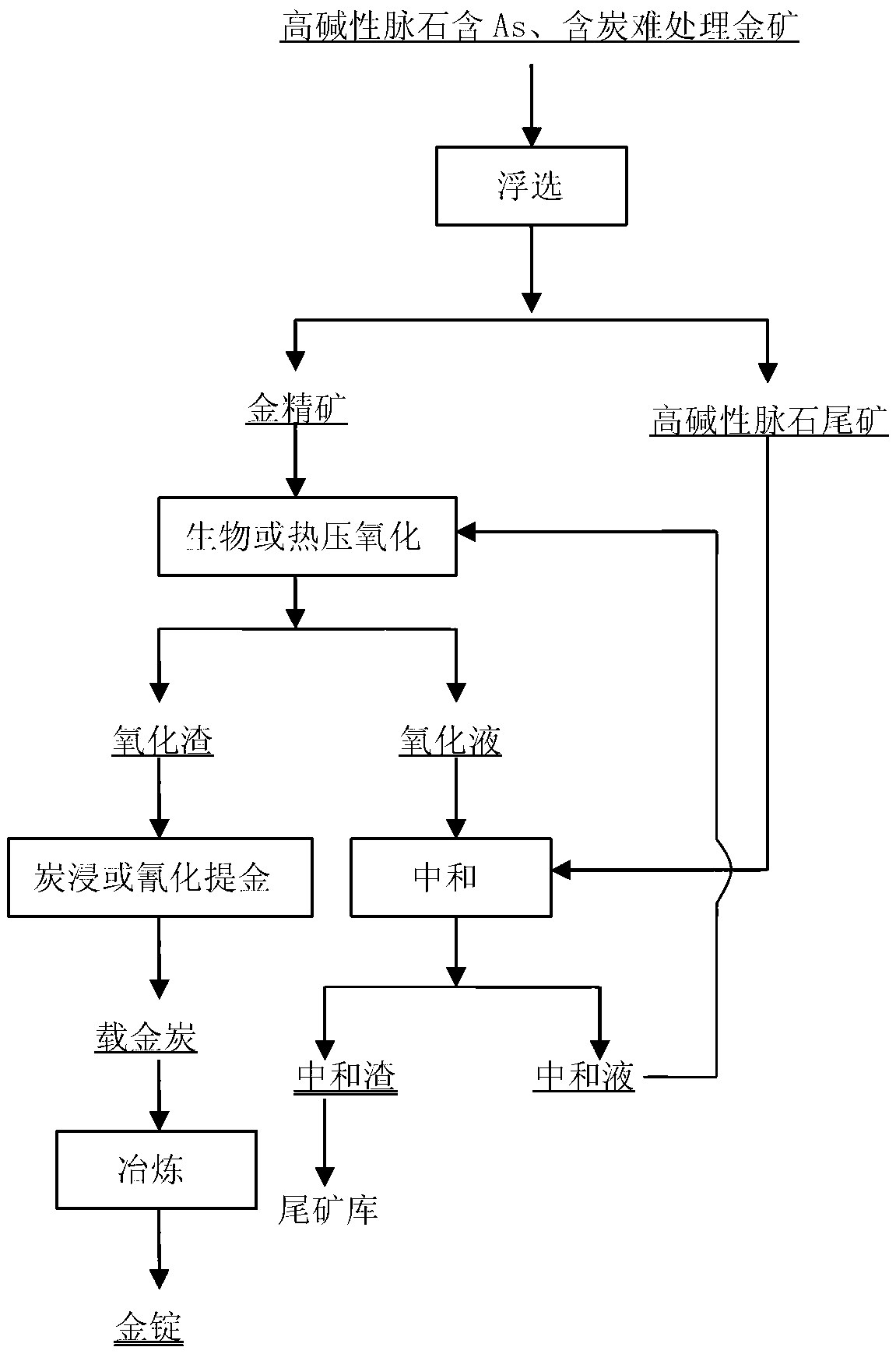

Method for extracting gold from high basic gangue containing arsenic and carbon

A technology of high alkalinity and gangue, applied in the field of gold extraction from arsenic-containing and carbon-containing high-alkaline gangue, can solve the problems of high neutralization cost and high Fe3+, and achieve the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

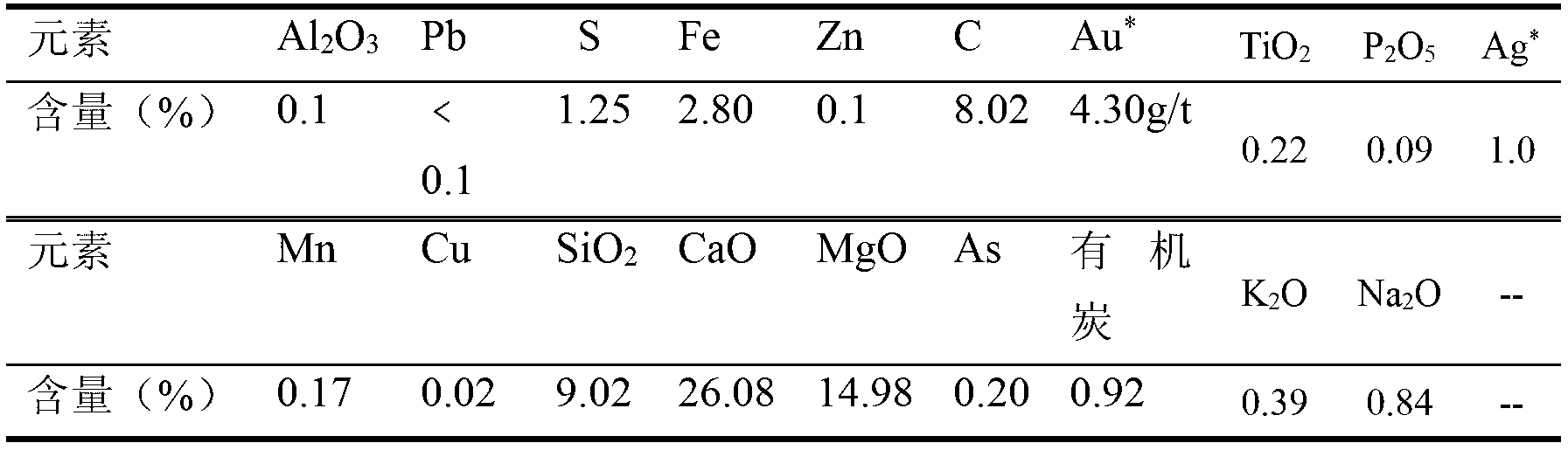

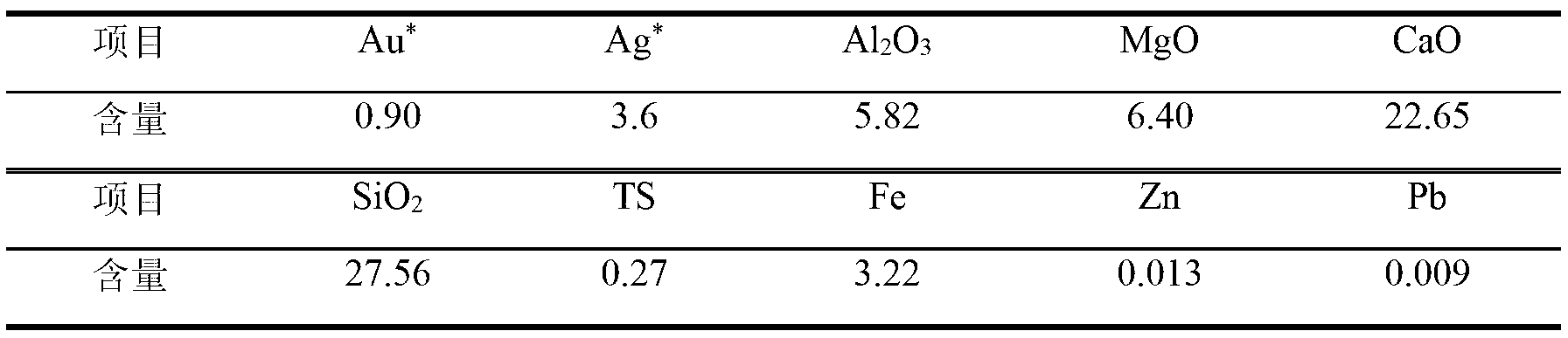

example 1

[0035] Example 1: Au, S, CaO, MgO, Al2O3 contents are respectively 3g / t, 1.20%, 20.00%, 12.00%, 1.92% highly alkaline gangue containing As, carbon containing microfine refractory gold ore for flotation , the gold content of gold concentrate is 25g / t, the contents of pyrite and arsenopyrite are 45.32% and 2.02% respectively, and the sulfide wrapped gold such as pyrite is 70.50%; the contents of CaO, MgO and Al2O3 in flotation tailings are 20.05% respectively. %, 5.42%, 4.13%. The gold concentrate adopts biological oxidation-carbon leaching gold, the gold leaching rate is 96.08%, the pH of the oxidation solution is 1.20, the Fe and As contents are 30.02g / L and 1.11g / L respectively, the Fe / As ratio is 27.04, Fe2+=50mg / L, As3+=0.15mg / L. Tailings are used to neutralize the oxidation solution. When the amount of tailings is 305kg / m3 oxidation waste liquid, the pH of the neutralization solution is 6.58. The content of each harmful metal ion in the neutralization solution reaches th...

example 2

[0036] Example 2: Floating refractory gold ores with highly alkaline gangue containing As and carbon containing microfine particles with Au, S, CaO, MgO, and Al2O3 contents of 4g / t, 2.00%, 25.23%, 14.24%, and 1.92% respectively The gold content in the flotation gold concentrate is 28.08g / t, the contents of pyrite and arsenopyrite are 50.36% and 4.00% respectively, and the gold contained in pyrite and other sulfides is 72.08%; the flotation tailings CaO, MgO, Al2O3 The contents are 28.15%, 16.05%, and 5.13%, respectively. The obtained gold concentrate was extracted by hot-pressed oxidation-carbon leaching, the gold leaching rate was 97.15%, the pH of the oxidation solution was 0.53, the Fe and As contents were 32g / L and 0.5g / L respectively, the Fe / As ratio was 64.00, and the Fe2+ =30mg / L, As3+=0.12mg / L. Tailings are used to neutralize the oxidation solution. When the amount of tailings is 400kg / m3 oxidation waste liquid, the pH of the neutralization solution is 7.59, and the c...

example 3

[0037]Example 3: Floating highly alkaline gangue containing As and carbon-containing fine-grained refractory gold ores with Au, S, CaO, MgO, and Al2O3 contents of 6g / t, 1.85%, 30.0%, 16.0%, and 3.0% respectively The gold content in the flotation gold concentrate is 35.06g / t, the contents of pyrite and arsenopyrite are 70% and 4.0% respectively, and the sulfide wrapping gold such as pyrite is 74%; the flotation tailings CaO, MgO, Al2O3 The contents are 33%, 18.02%, and 6.00%, respectively. The obtained gold concentrate adopts biological oxidation-carbon leaching gold, the gold leaching rate is 97.15%, the pH of the oxidation solution is 0.90, the Fe and As contents are 40.00g / L and 3.0g / L respectively, the Fe / As ratio is 13.3, and the Fe2+ =100mg / L, As3+=0.40mg / L. Tailings are used to neutralize the oxidation solution. When the amount of tailings is 338kg / m3 oxidation waste liquid, the pH of the neutralization solution is 7.05, and the content of each harmful metal ion in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com