Method for purifying zinc sulfide solution

A zinc sulfate solution and solution technology, applied in the direction of improving process efficiency, etc., can solve the problems of ineffective recovery of suspended solids, lower raw material utilization efficiency, and large zinc powder consumption, so as to eliminate adverse effects and reduce zinc powder Consumption, the effect of low zinc powder consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

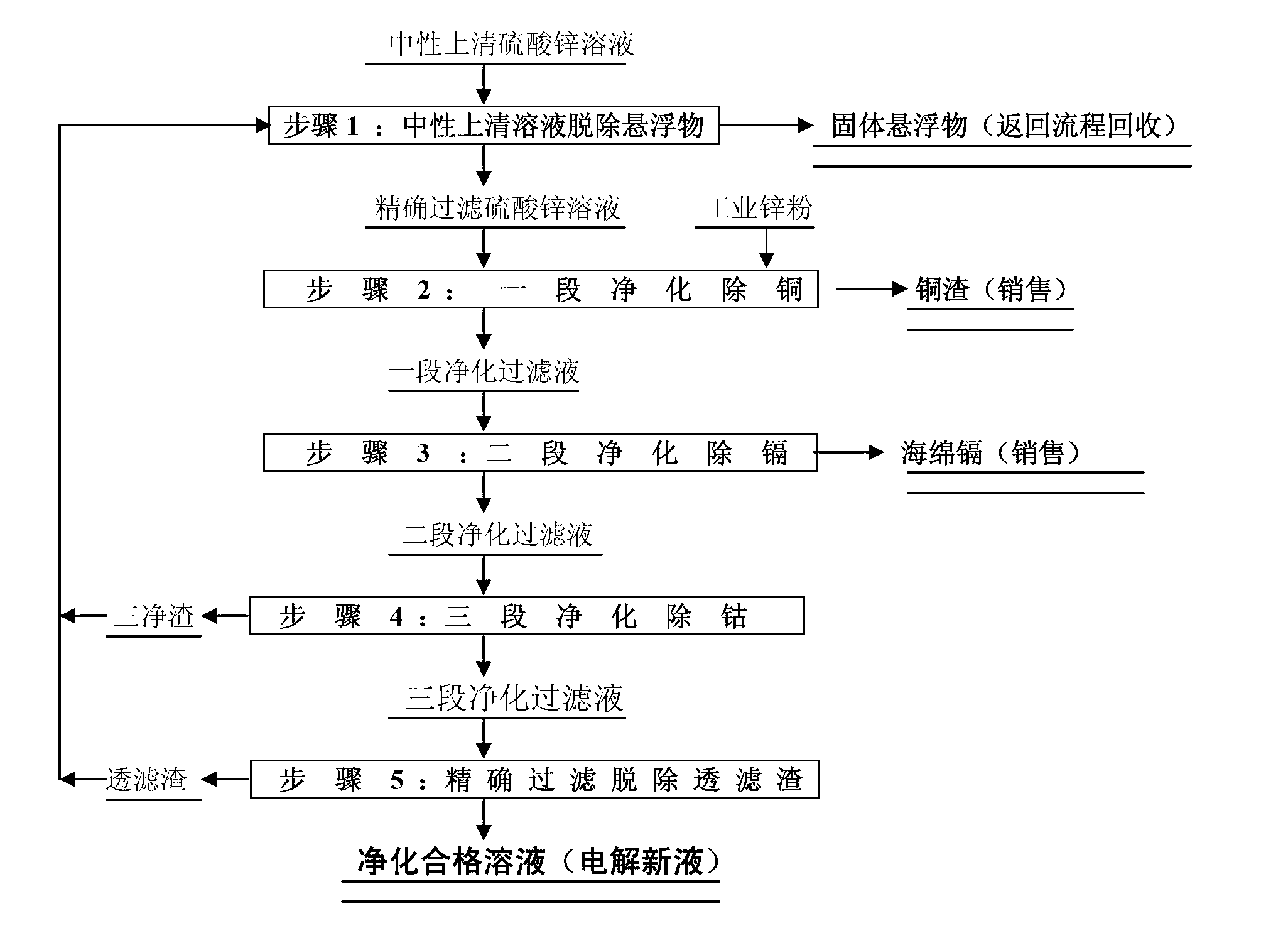

Method used

Image

Examples

no. 1 example

[0029] Present embodiment is the first example of the purification method of zinc sulfate solution of the present invention, comprises the steps:

[0030] (1) Neutral supernatant solution to remove suspended solids: use Φ2600mm Sean filter to 40m 3 Precisely filter the zinc sulfate neutral supernatant solution with 800mg / L of solid floating matter, Cu0.4g / L, Cd0.4g / L, Co1.0mg / L, temperature of 55°C, and pH value of 5.0 at a speed of / h. The suspended matter content of the filtered solution is 12mg / L;

[0031](2) One-stage purification and copper removal: 70m of the solution filtered by Sean filter 3 , pumped into 80m 3 Add 33.6kg of zinc powder to the purification tank of the first section, stir at a temperature of 55°C for 90 minutes, then filter with a filter press for solid-liquid separation, and obtain 46kg of copper slag containing Cu59.3% and a section of copper slag containing Cu10.5mg / L Purification Filtration Solution 70m 3 ;

[0032] (3) Second-stage purificatio...

no. 2 example

[0036] Present embodiment is the second example of the purification method of zinc sulfate solution of the present invention, comprises the steps:

[0037] (1) Neutral supernatant solution to remove suspended solids: use Φ2600mm Sean filter to 40m 3 Precisely filter the zinc sulfate neutral supernatant solution with 1400mg / L of solid floating matter, Cu0.7g / L, Cd0.8g / L, Co3.0mg / L, temperature of 60°C, and pH value of 5.2 at a speed of / h. The suspended matter content of the filtered solution is 16mg / L;

[0038] (2) One-stage purification and copper removal: 70m of the solution filtered by Sean filter 3 , pumped into 80m 3 Add 58.8kg of zinc powder to the first-stage purification tank, stir at 60°C for 90 minutes, then filter with a filter press to separate solids and liquids, and obtain 81kg of copper slag containing Cu60.1%, and a section of copper slag containing Cu12.3mg / L Purification Filtration Solution 70m 3 ;

[0039] (3) Second-stage purification and removal of ca...

no. 3 example

[0043] Present embodiment is the 3rd example of the purification method of zinc sulfate solution of the present invention, comprises the steps:

[0044] (1) Neutral supernatant solution to remove suspended solids: use Φ2600mm Sean filter to 40m 3 Precisely filter the zinc sulfate neutral supernatant solution with 2000mg / L of solid floating matter, Cu1.0g / L, Cd1.2g / L, Co5.0mg / L, temperature 65°C, and pH value 5.4 at a speed of / h. The suspended matter content of the filtered solution is 24mg / L;

[0045] (2) One-stage purification and copper removal: 70m of the solution filtered by Sean filter 3 , pumped into 80m 3 Add 84kg of zinc powder to the first-stage purification tank, stir at 65°C for 90 minutes, then filter with a filter press to separate solid and liquid, and obtain a first-stage purification filter containing 118kg of Cu59.0% copper slag and Cu5.5mg / L Liquid 70m 3 ;

[0046] (3) Second-stage purification and removal of cadmium: 70m of the first-stage purification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com