Automobile door glass guide groove seal bar adhesive material and applications thereof

A technology for glass run channels and car doors, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the size of the sealing strip material cannot meet the assembly of the whole vehicle, affecting the size and length of the finished sealing strip, etc. problems, to achieve the effect of reducing the secondary baking process, eliminating dimensional defects and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A rubber compound for sealing strips of glass run grooves of automobile doors, the raw materials of which are composed of the following components in parts by weight:

[0050] EPDM K8550 80 parts, EPDM K4869 40 parts,

[0051] 10 parts of active zinc oxide, 2 parts of stearic acid, 3 parts of dispersant L-24, 3 parts of polyethylene glycol,

[0052] FEF grade carbon black N550 110 parts, SRF grade carbon black N774 70 parts, light calcium carbonate 50 parts,

[0053] Active reinforcing agent Great-E1 50 parts, paraffin oil R-2291 70 parts, moisture absorbent 8 parts,

[0054] 0.3 parts of anti-scorch agent, 1.45 parts of sulfur, 1.5 parts of accelerator BZ, 0.8 parts of accelerator DM,

[0055] Accelerator TMTD 0.4 parts, accelerator TRA 0.4 parts, accelerator DTDM-80 1.2 parts.

[0056] In the above raw material composition of this rubber compound, the combination of EPDM K8550 and EPDM K4869 with low ethylene content is used as the main body, and high-structure, lo...

Embodiment 2-7

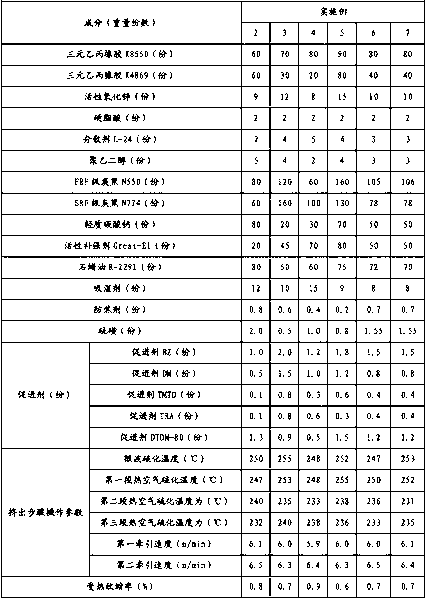

[0077] Embodiments 2-7 are respectively a kind of rubber compound for the glass run channel of an automobile door. The types of raw materials for each implementation are the same as those in Embodiment 1, the only difference being the difference in parts by weight used, as shown in the following table Show:

[0078]

[0079] The above-mentioned automotive door glass run channel sealing strip rubber materials provided in Examples 2-7 all have applications for processing the automotive door glass run channel sealing strip, and the processing methods are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com