Purification method of echinocandins antifungal drug anidulafungin

Anidungin and antifungal technology are applied in the field of purification of echinocandin-type antifungal anidungin, which can solve the problems of long purification and separation time, difficult post-processing, few samples to be processed, etc. The effect of short separation time, low equipment cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

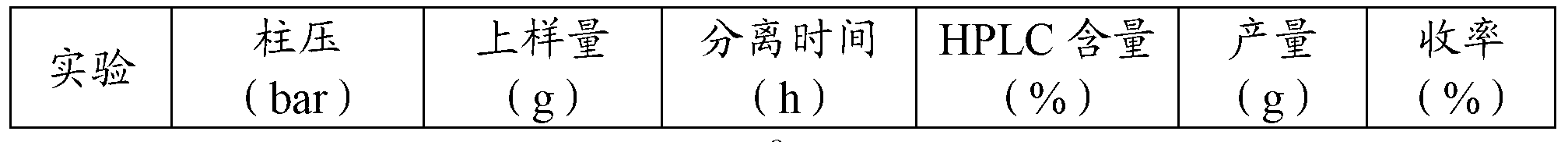

[0034] Take 22.5g of the crude product of Anifungin, add methanol to make it fully dissolve, then add 45g of amorphous silica gel (200-300 mesh) and stir evenly, and obtain a dry sample of Anidulungin silica gel after drying.

[0035] Pack 565g of amorphous silica gel (200-300 mesh) in a chromatographic column with a height-to-diameter ratio of 8:1, fill the dry sample of anifungin silica gel evenly on the top of the chromatographic column, and then use dichloromethane-methanol The mixed solution is used as the elution solvent for gradient pressure elution. The volume ratio of dichloromethane to methanol in the first gradient elution solvent is 90:10, and the volume ratio of dichloromethane to methanol in the second gradient elution solvent is 80. :20, the column pressure in the chromatographic column is 5bar. According to the monitoring result of high-performance liquid chromatography, collect the eluent with anifungin content greater than 98%. The amounts of the first gradi...

Embodiment 2

[0039] Take 20.5 g of crude anifungin, add tetrahydrofuran to dissolve it fully, then add 20.5 g of spherical silica gel (300 mesh to 400 mesh) and stir evenly, and dry it to obtain a dry sample of anidulungin silica gel.

[0040] Fill 410g of spherical silica gel (300 mesh to 400 mesh) in a chromatographic column with a height-to-diameter ratio of 9:1, fill the dry sample of anifungin silica gel evenly on the top of the chromatographic column, and then use a tetrahydrofuran-methanol mixed solution as the The elution solvent is subjected to gradient pressure elution, the volume ratio of tetrahydrofuran and methanol in the first gradient elution solvent is 90:10, and the volume ratio of tetrahydrofuran and methanol in the second gradient elution solvent is 75:25. The column pressure is 6bar. According to the monitoring result of high-performance liquid chromatography, collect the eluent with anifungin content greater than 98%. The amounts of the first gradient elution solvent ...

Embodiment 3

[0044] Take 15.2 g of the crude product of Anifungin, add dichloromethane-methanol to fully dissolve it, then add 45.6 g of amorphous silica gel (100 mesh to 200 mesh) and stir evenly, and dry it to obtain a dry sample of Anidifungin silica gel.

[0045] Fill 456g of amorphous silica gel (100 mesh to 200 mesh) in a chromatographic column with a height-to-diameter ratio of 12:1, fill the dry sample of anifungin silica gel evenly on the top of the chromatographic column, and then use a chloroform-methanol mixed solution Gradient pressure elution is carried out as the elution solvent, the volume ratio of chloroform and methanol in the first gradient elution solvent is 90:10, the volume ratio of chloroform and methanol in the second gradient elution solvent is 70:30, and the chromatography column The column pressure inside is 2 bar. According to the monitoring result of high-performance liquid chromatography, collect the eluent with anifungin content greater than 98%. The amounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com