Hollow sandwiched plate with cellular core plate and preparation method thereof

A honeycomb structure and hollow technology, applied in the field of materials, can solve the problems of easy corrosion, poor water resistance, and poor practicability, and achieve the effect of high porosity and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

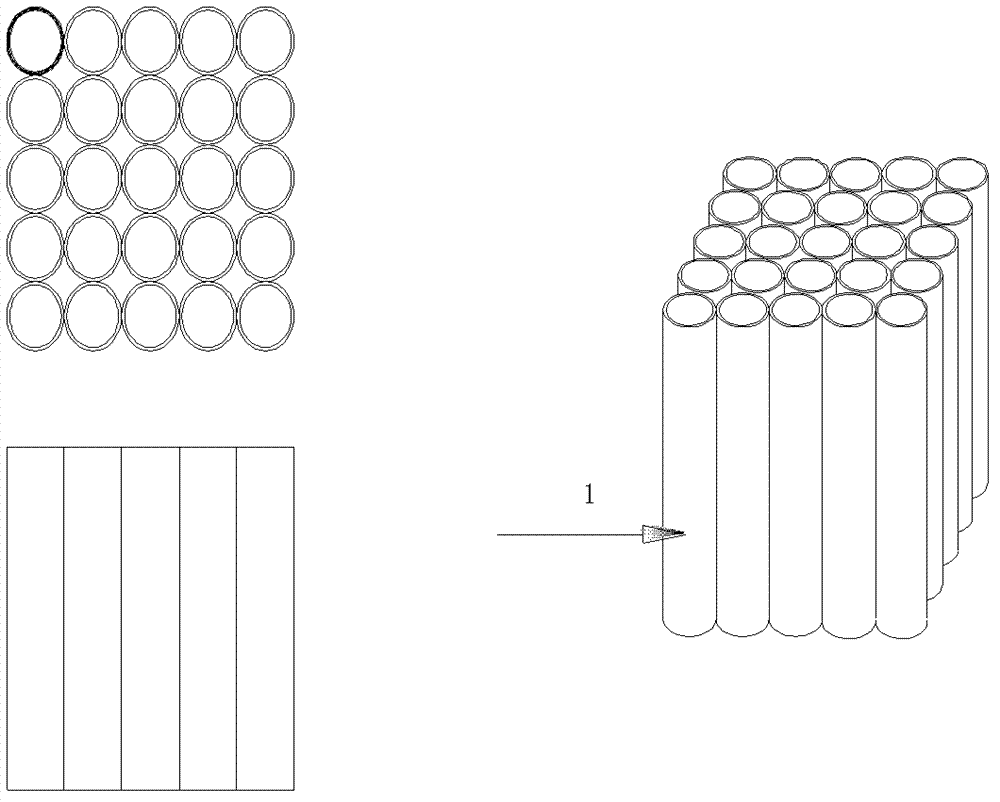

[0038] (1) The PP resin is spun into PP hollow fibers with a diameter of 0.1 mm by means of melt-spinning spinning with an annular hollow spinneret with a diameter of 0.1 mm;

[0039] (2) Dip the polyurethane glue at 500g / m 2 Fix and glue the PP hollow fiber into a hollow fiber bundle with a circular cross-section and a porosity of 70%, surround the hollow fiber bundle with a baffle, and apply 200N / mm evenly to the surface of the baffle 2 The force lasts for 24 hours;

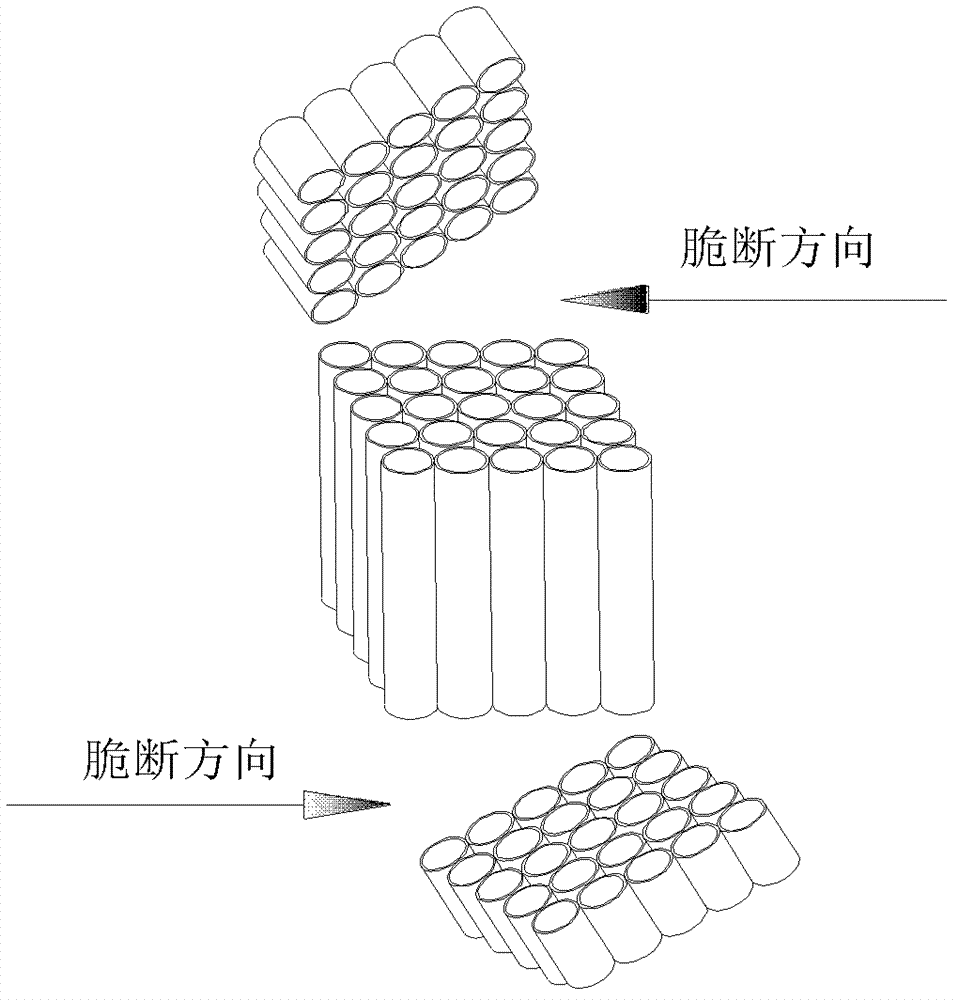

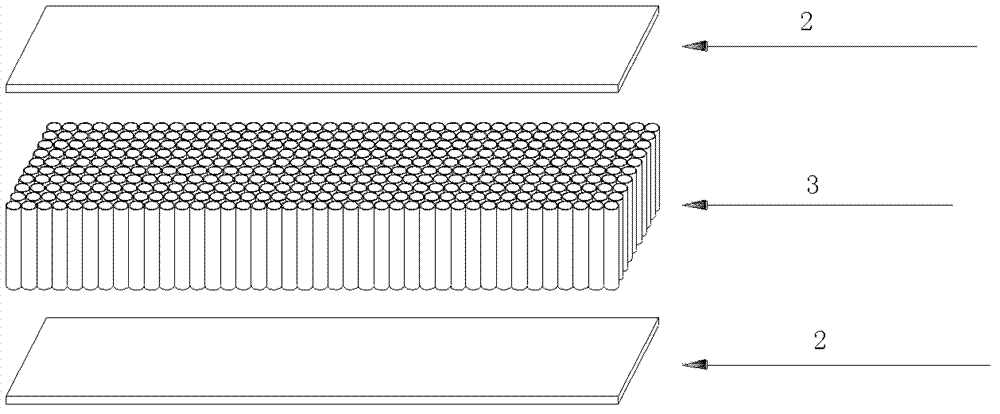

[0040] (3) After the polyurethane glue is solidified, place the firmly bonded hollow fiber bundles in an environment filled with liquid nitrogen, and perform transverse brittle fracture on the upper and lower sides of the hollow fiber bundles according to the thickness of the core plate of 50mm, and remove the upper and lower parts of the truncated , the upper and lower surfaces of the remaining middle part will keep the hollow channels of the hollow fibers intact, that is, a circular core material of the sand...

Embodiment 2

[0043] (1) A C-shaped hollow spinneret with a spinneret aperture of 10 mm is used to spin the PP resin into a PP hollow fiber with an aperture of 10 mm by the method of melt spinning;

[0044] (2) Dip the polyurethane glue at 500g / m 2 Fix the PP hollow fiber into a hollow fiber bundle with a circular cross-section and a porosity of 20% with a certain amount of glue, surround the hollow fiber bundle with a baffle, and apply 200N / mm evenly to the surface of the baffle 2 The force lasts for 24 hours;

[0045] (3) After the polyurethane glue is solidified, place the firmly bonded hollow fiber bundles in an environment filled with liquid nitrogen, and perform transverse brittle fracture on the upper and lower sides of the hollow fiber bundles according to the thickness of the core plate of 50mm, and remove the upper and lower parts of the truncated , the upper and lower surfaces of the remaining middle part will keep the hollow channels of the hollow fibers intact, that is, a circ...

Embodiment 3

[0048] (1) The PET resin is spun into a PET hollow fiber whose aperture is 1 mm by solution spinning with a spinneret aperture of 1 mm in an annular hollow spinneret;

[0049](2) Dip the impregnating glue at 550g / m 2 The amount of glue used is to fix the PET hollow fiber into a hollow fiber bundle with a square cross-section and a porosity of 30%, surround the hollow fiber bundle with a baffle, and apply 250N / mm evenly to the surface of the baffle 2 The force lasts for 24 hours;

[0050] (3) After the impregnation gel is solidified, place the firmly bonded hollow fiber bundles in an environment filled with liquid nitrogen, and carry out transverse brittle fracture on the upper and lower sides of the hollow fiber bundles according to the thickness of the core plate of 30mm, and the upper and lower parts of the truncated After removal, the upper and lower surfaces of the remaining middle part will maintain intact hollow fiber hollow channels, that is, a square core material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com