Inner-cooling bonded abrasive grinding disc

A technology of consolidating abrasives and grinding discs, which is applied in the direction of abrasives, bonded grinding wheels, and metal processing equipment. It can solve the problems of shortened life of grinding discs, reduced processing efficiency, burns of grinding discs and workpieces, and achieves obvious cooling effects. Uniform cooling effect and good surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

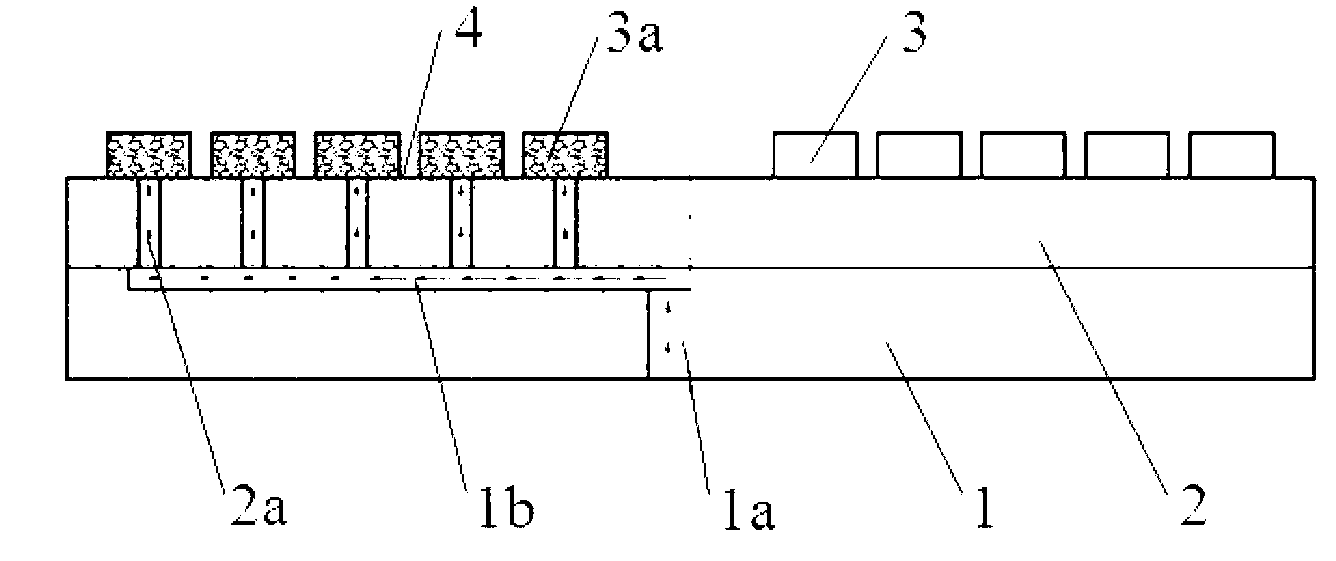

[0010] The specific implementation manner of the patent of the present invention will be described below with reference to the accompanying drawings and technical solutions. in the attached figure 1 Among them, the grinding disc is composed of a porous grinding block 3 containing abrasives, a substrate 2 with a plurality of holes 2a, and a splitter plate 1 with a central hole 1a and a groove 1b, and each grinding block 3 is fixed by an adhesive 4 At one end of a hole 2a on the base plate 2, the base plate 2 is fixedly connected with the side of the splitter plate 1 with the groove 1b. When in use, the splitter plate 1 of the grinding disc is fixedly connected with the grinder.

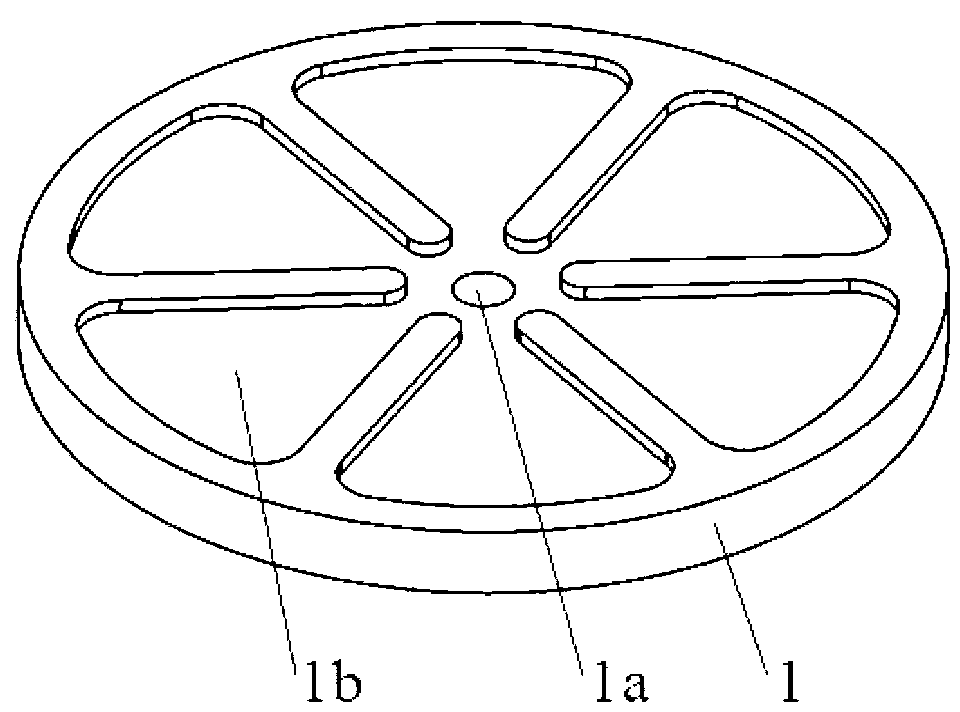

[0011] figure 2 It is a schematic diagram of a splitter plate with fan-shaped grooves. There is a central hole 1a and six fan-shaped grooves 1b on the splitter plate 1 in the figure. The central hole 1a and fan-shaped grooves 1b are connected to each other. This structure can adapt to various structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com