Method for manufacturing silver nanowire

A manufacturing method and technology of silver nanowires, which are applied in the field of metal functional materials and nanomaterials, can solve problems such as difficult mass production, wide distribution, and short wire lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

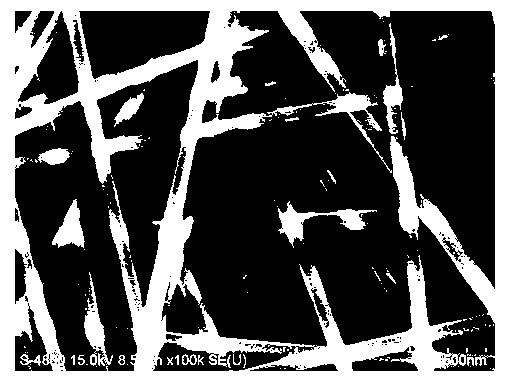

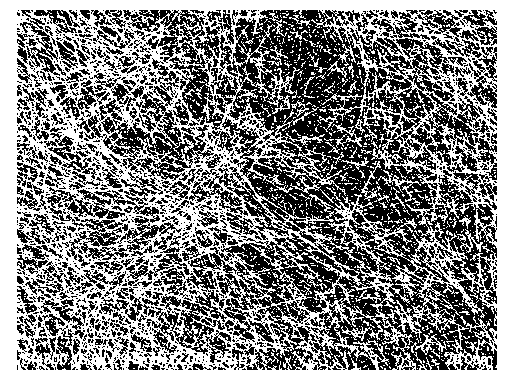

[0039] Please refer to figure 1 Shown, the present invention discloses a kind of manufacturing method of silver nanowire, it comprises the steps:

[0040] (a). A mixed solution is provided, containing at least one protective agent and an additive in the mixed solution, the additive being a halide and / or a compound capable of forming an intolerable salt with silver ions;

[0041] (b). Provide a silver precursor solution containing silver compounds, and add the silver precursor solution to the mixed solution at least twice;

[0042] (c). Separating and obtaining the silver nanowires.

[0043] Specifically, in step (a), the protective agent includes but is not limited to:

[0044] Various molecular weight polyvinylpyrrolidone (PVP, (C 6 h 9 NO)n), derivatives of polyvinylpyrrolidone, polyvinyl alcohol (PVA, (C 2 h 4 O)n), polyethylene oxide (PEO, (CH 2 CH 2 O) n), sodium lauryl sulfate (C 12 h 25 SO 4 Na), dodecylamine (C 12 h 27 N), octadecylamine (CH 3 (CH 2 ) 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com