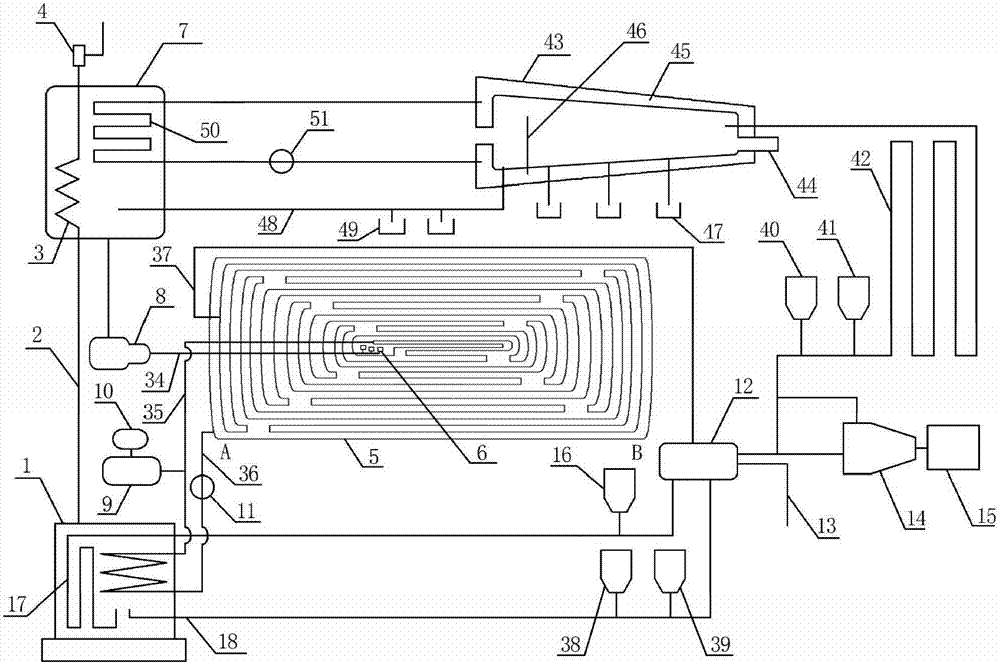

Recycling device capable of decomposing and burning matters through vapor clash

A combustion cycle and steam technology, which is applied in steam generation, evaporation, separation methods, etc., can solve the problems of complicated and multi-stage processes, high investment costs, and heavy machines, and achieve high thermal work efficiency, reduce production costs, and solve resource waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

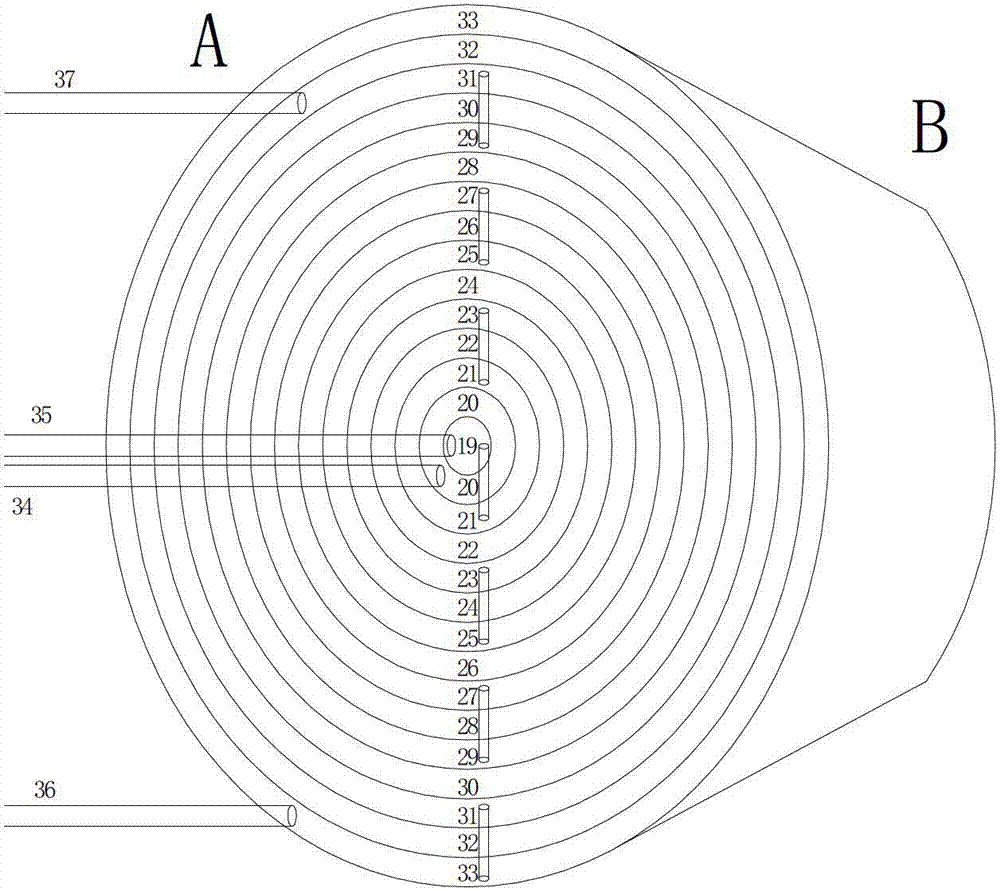

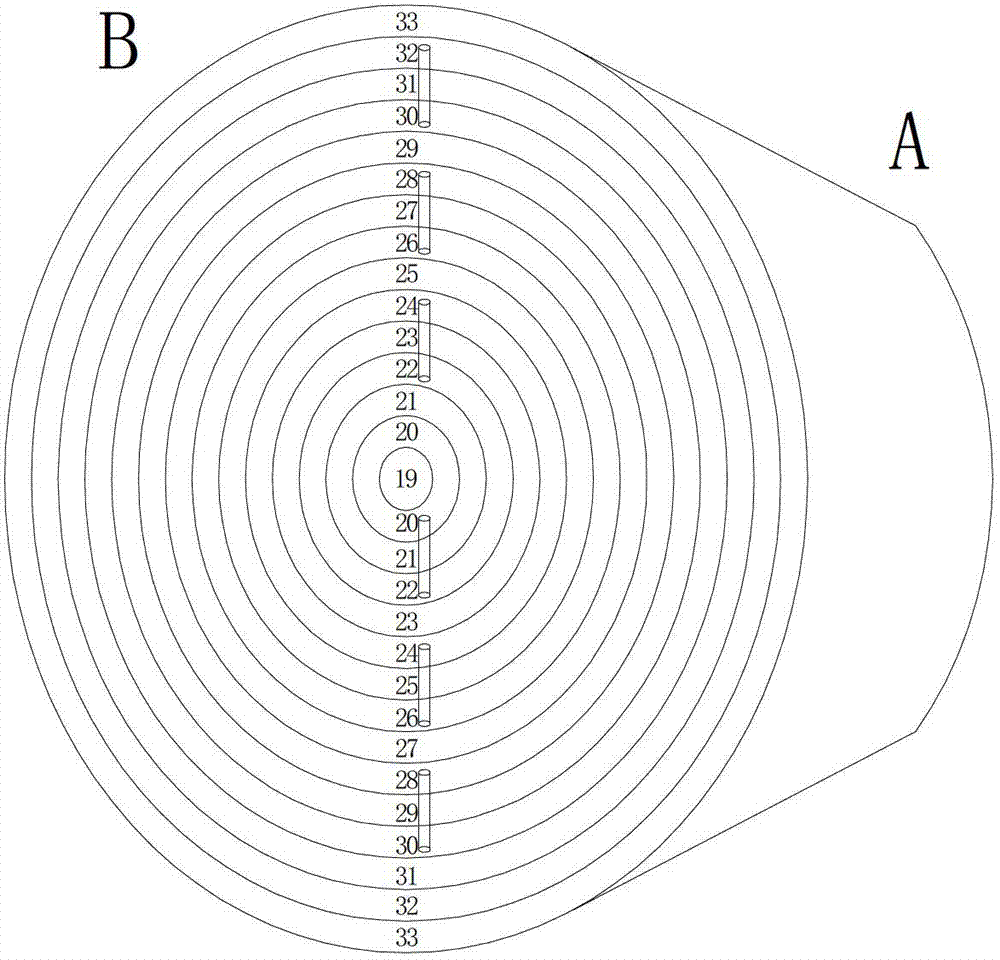

[0050] In the dry steam generator of the present invention, there is no concentrated water and no scale in the movement of the steam-producing fluid, and the dry steam generator matches the pressure energy of the electronically controlled mechanical pump in the generator for spraying by the spray device, which belongs to the dry spray explosion steam production , breaking through hundreds of years of heating a large amount of water at one time and repeating work and boiling bubbles to produce steam. The steam pressure and temperature are not proportional to high temperature and low pressure steam production. The heat energy is transferred to the dry steam generator, and the atomized wet airflow in the dry steam generator is heated, so that all the water expands instantly to absorb the heat in the heat transfer oil at the front end. The working temperature of the heat transfer oil is adjustable from 100 to 320 degrees. The steam temperature can be controlled within 80 to 300 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com