Real-time tunable confocal microscopic imaging system

A confocal microscopy and imaging system technology, applied in medical science, diagnosis, diagnostic recording/measurement, etc., can solve the problems of application limitation, slow scanning rate, unadjustable imaging rate, etc., to achieve adjustable imaging rate and strong universality The effect of sex, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] The real-time tunable confocal microscopic imaging system of the present invention includes a laser scanning microscopic imaging system, a first laser, a photodiode and a confocal microscopic imaging control system.

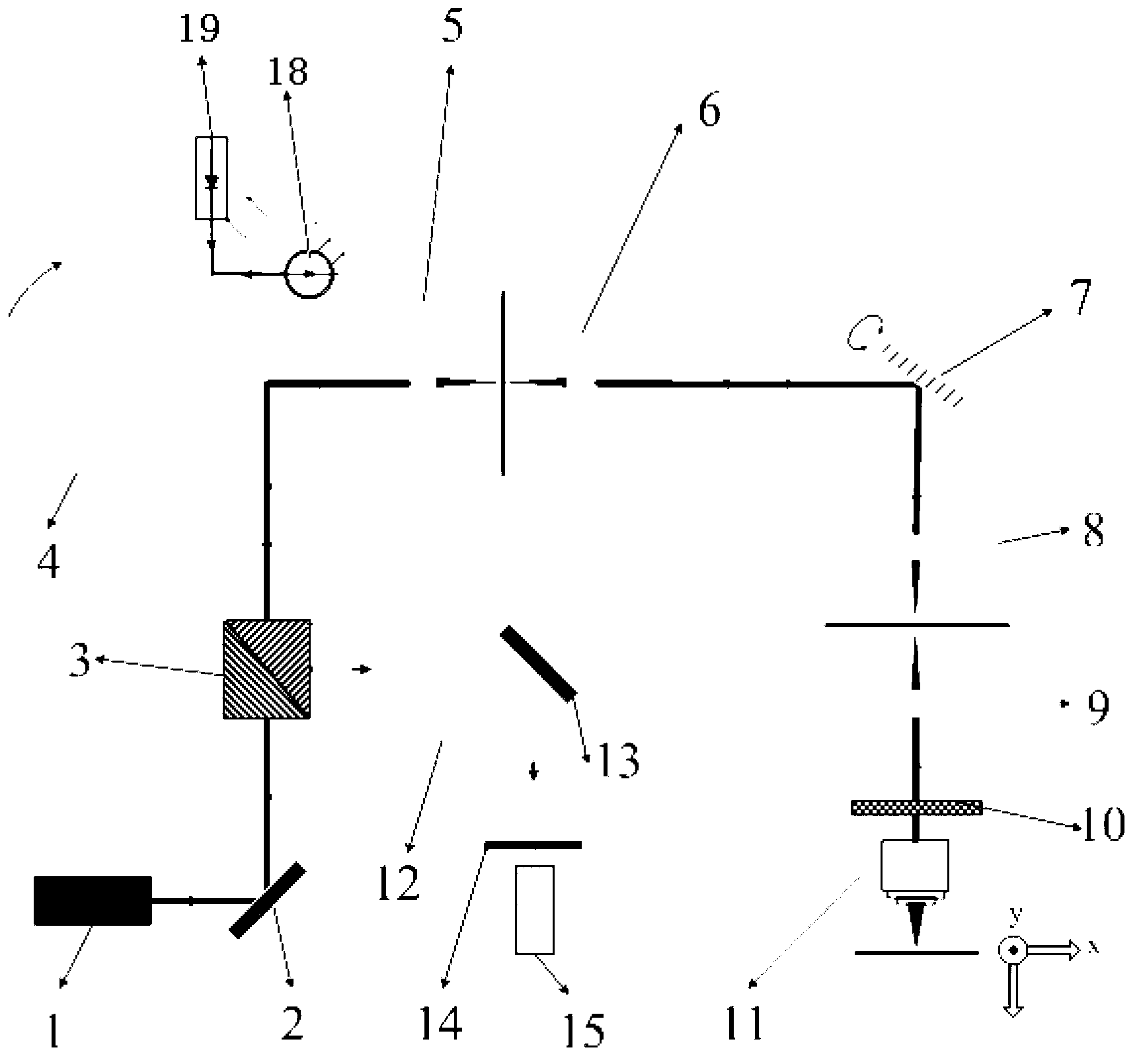

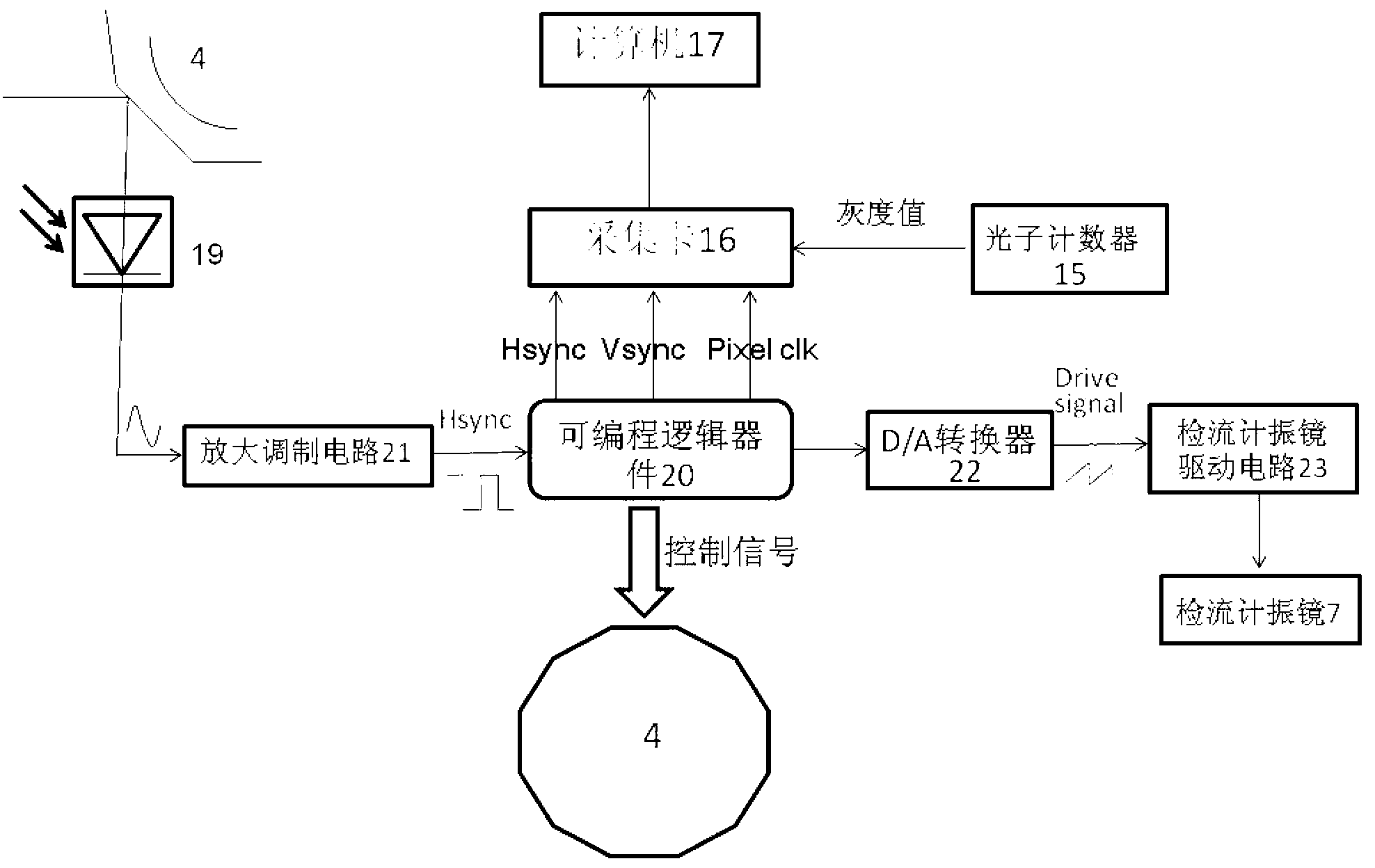

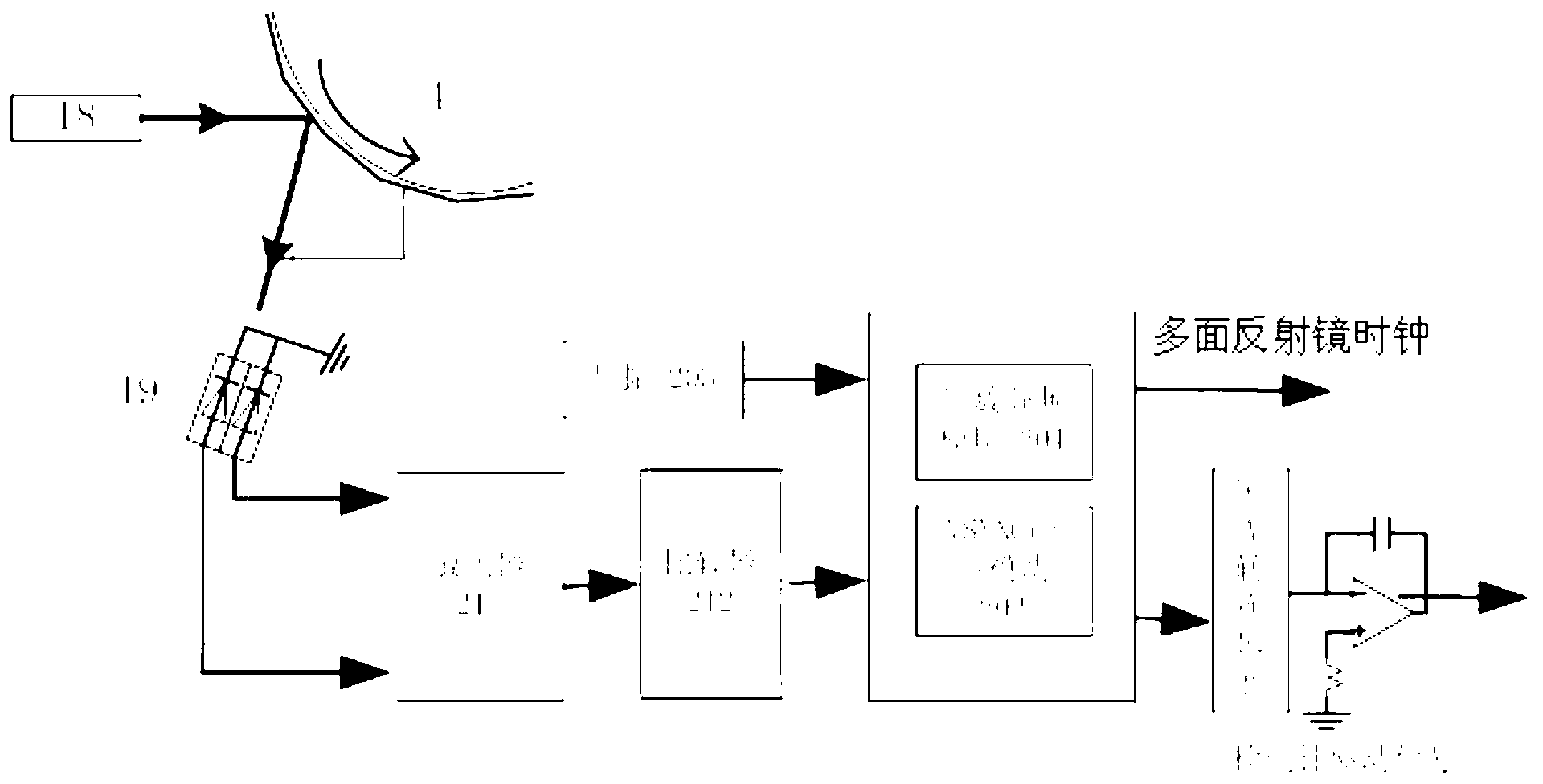

[0017] Such as figure 1 , figure 2 As shown, the structure of the laser scanning microscopic imaging system adopted in the present invention is similar to the structure of the laser scanning microscopic imaging system in the prior art, and it includes a second laser 1, a first reflecting mirror 2, a polarizing beam splitter 3 , polygon mirror 4, first lens 5, second lens 6, galvanometer vibrating mirror 7, third lens 8, fourth lens 9, quarter wave plate 10, microscope objective lens 11, fifth lens 12 , second reflector 13, confocal aperture 14, photon counter 15, acquisition card 16 and computer 17; Its working process is: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com