Pork and beef combined bacon and production method thereof

A production method and beef technology, which are applied in the field of pork and beef combined bacon and the production field thereof, can solve the problems of high cholesterol content, poor adhesion of bacon, heavy mutton taste, etc., and achieve the reduction of cholesterol content, good adhesion effect, and reduction of beef mutton. taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

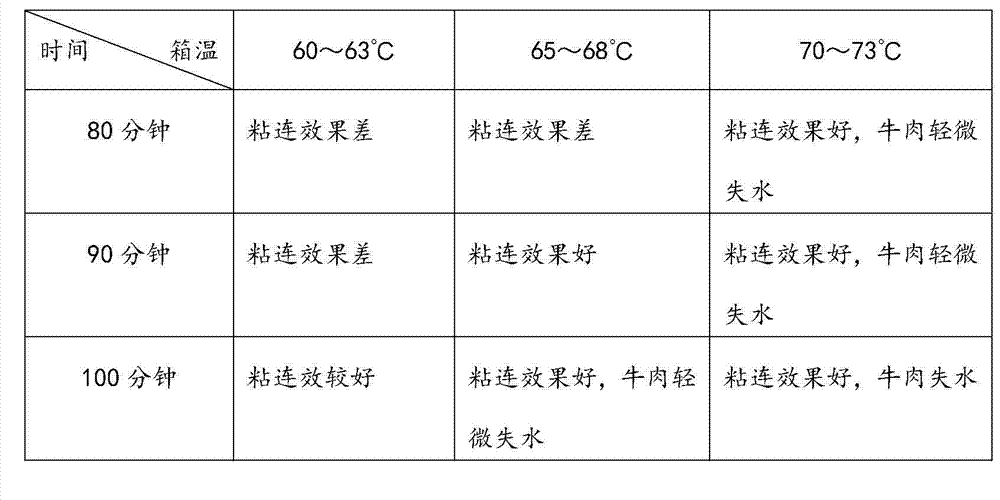

Image

Examples

Embodiment 1

[0026] Pork and beef combined bacon, prepared from the following raw materials according to the following weight: 290kg pork belly, 340kg beef front slope, 35kg pork front slope, 205kg ice water, 11kg salt, 1kg monosodium glutamate, 2kg compound phosphate, 1kg carrageenan, Sodium nitrite 0.01kg, Monascus red 0.01kg, spices 3kg, glutamine transaminase 2kg, white sugar 4kg, glucose 2kg, soybean protein 8kg, starch 15kg, smoke liquid 0.4kg.

[0027] The production steps of this combined bacon are as follows:

[0028] (1) Pretreatment: remove pig hair, butter, cartilage, lymphoma, blood vessels, tendons, bones, broken bones, etc. from the pork belly, and remove excess fat and foam layer. The thickness of the pork belly is controlled within 25mm. The thickness of the fat layer is controlled within 10mm; the cartilage, lymphoma, blood vessels, tendons, bones, broken bones, etc. are removed from the pork and beef meat, and the thickness of the pork and beef meat is controlled at 20mm...

Embodiment 2

[0044] Combination of pork and beef bacon, prepared from the following raw materials according to the following weight: pork belly 305kg, beef front slope 360kg, pork front slope 50kg, ice water 220kg, salt 12.5kg, monosodium glutamate 2.5kg, compound phosphate 3kg, carrageenan 2kg, sodium nitrite 0.03kg, red yeast rice 0.02kg, spices 4.5kg, glutamine transaminase 3.8kg, white sugar 5kg, glucose 3kg, soybean protein 10kg, starch 18kg, smoke liquid 0.55kg.

[0045] The production steps of this combined bacon are the same as in Example 1.

Embodiment 3

[0047] Pork and beef combined bacon is prepared from the following raw materials according to the following weight: pork belly 320kg, beef front slope 370kg, pork front slope 65kg, ice water 235kg, salt 14kg, monosodium glutamate 3kg, compound phosphate 4kg, carrageenan 3kg, Sodium nitrite 0.04kg, Monascus red 0.03kg, spices 6kg, glutamine transaminase 5kg, white sugar 7kg, glucose 4kg, soybean protein 12kg, starch 20kg, smoke liquid 0.7kg.

[0048] The production steps of this combined bacon are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com