Solid catalyst component for olefin polymerization, catalyst for olefin polymerization, and method for producing olefin polymer

A technology of olefin polymers and solid catalysts, which is applied in the field of solid catalyst components for olefin polymerization, can solve problems such as hydrogen limit, heat resistance strength reduction, and cost problems, and achieve high hydrogen activity and polymerization activity with low load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

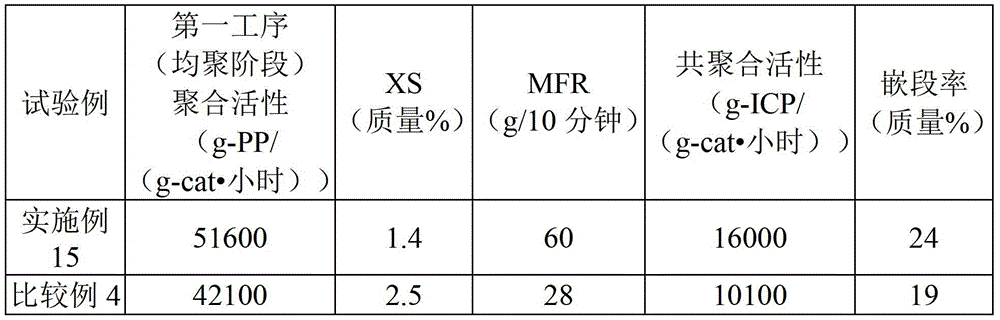

Examples

Embodiment 1)

[0193] (1) Preparation of solid catalyst components

[0194] 10 g of diethoxymagnesium and 80 mL of toluene were placed in a 500-mL round-bottomed flask with a capacity of a stirrer fully substituted with nitrogen to form a suspended state. Next, 20 mL of titanium tetrachloride was added to the suspension solution, and then the temperature was raised. When the temperature reached 80° C., 3.10 mL of diisobutylmalonate dimethyl was added, and the temperature was further raised to 110° C. Then, the reaction was carried out for 1 hour while stirring while maintaining the temperature of 110°C. Next, wash 3 times with 100 mL of toluene at 90°C, add 20 mL of titanium tetrachloride and 80 mL of toluene again, raise the temperature to 110°C, and react for 1 hour while stirring, then wash with 100 mL of n-heptane at 40°C 7 times , to obtain a solid catalyst component. Furthermore, the solid-liquid in this solid catalyst component was separated, and the titanium content in the solid ca...

Embodiment 2)

[0208] 20 g of diethoxymagnesium and 100 mL of toluene were placed in a 200-mL round-bottomed flask with a stirrer fully replaced with nitrogen gas to form a suspension, and then 3.00 mL of dimethyl diisobutylmalonate was added. , and keep the liquid temperature at 10°C to obtain a suspension solution. On the other hand, in a round-bottomed flask with a capacity of 500 mL of a stirrer fully replaced with nitrogen, a mixed solution composed of 40 mL of titanium tetrachloride and 60 mL of toluene was preliminarily charged, and the liquid temperature was kept at 10° C. for subsequent use. The above-mentioned suspension was added to this mixed solution. Next, the temperature of the liquid was raised from 10°C to 90°C over 80 minutes, and when it reached 90°C, 3.50 mL of dimethyl diisobutylmalonate was added, and the liquid temperature was maintained at 90°C while stirring. React for 2 hours.

[0209] After the reaction, the obtained solid product was washed 4 times with 200 mL o...

Embodiment 3)

[0212] Except for using 4.50 mL of diisobutyl dimethyl malonate instead of 3.10 mL of diisobutyl dimethyl malonate, the same operation was carried out as in Example 1 to prepare a solid catalyst component, and then carry out a polymerization catalyst preparation and polymerization reactions. The titanium content in the obtained solid catalyst component was 2.9% by mass.

[0213] Moreover, it carried out similarly to Example 1, and the polymerization activity per gram of solid catalyst component, the xylene-soluble content (XS) and MFR of the obtained polymer were calculated|required. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com