Distributed optical fiber leak monitoring system for lng storage tank

A technology of distributed optical fiber and monitoring system, applied in container discharge method, gas/liquid distribution and storage, container filling method, etc. requirements, it is difficult to determine the exact location of the leak point, etc., to achieve the effect of convenient long-distance transmission, convenient query, and intrinsic explosion-proof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

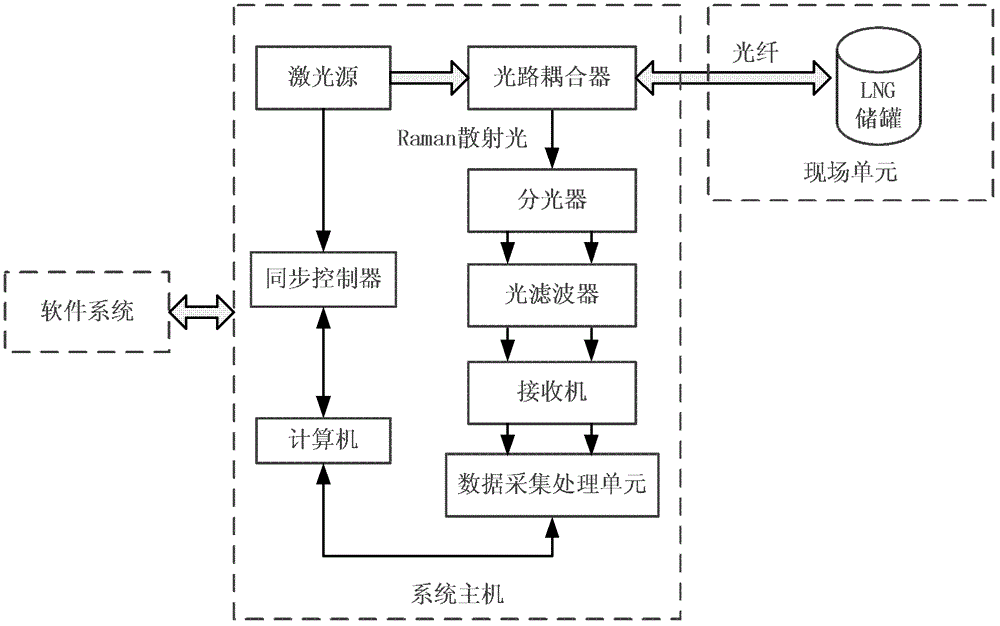

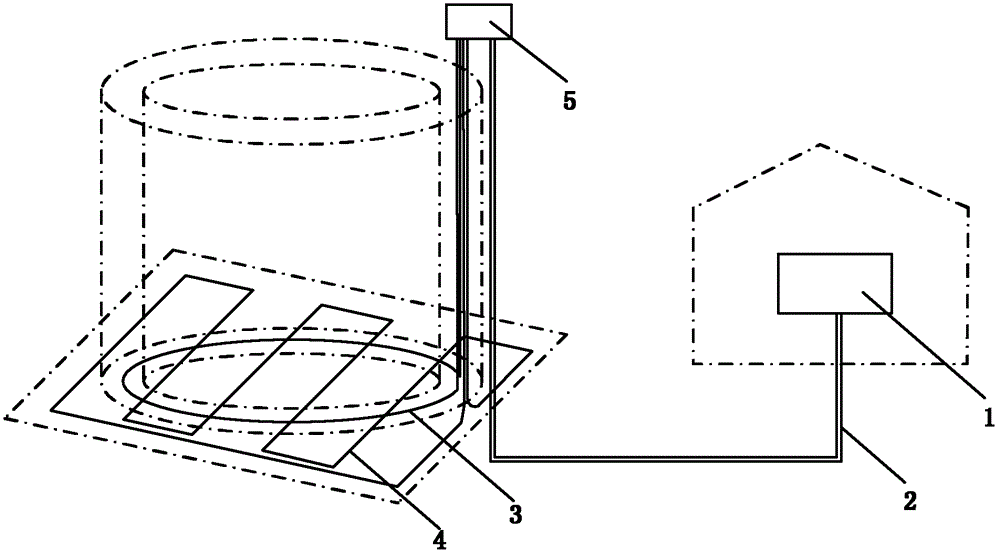

[0021] Example. This example is a test prototype of a distributed optical fiber leakage monitoring system for a 1000 square meter LNG storage tank. The principle block diagram is as figure 1 Shown.

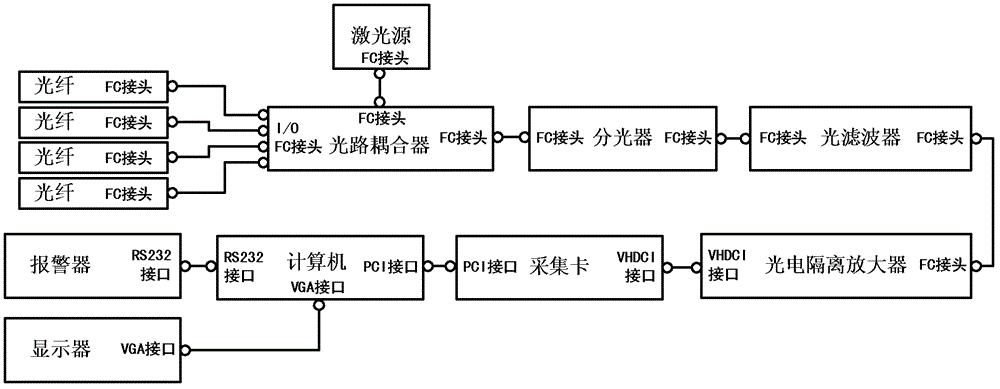

[0022] The system is composed of a leakage monitoring system host and a distributed optical fiber on site. The system host includes a laser source, an optical path coupler, an optical splitter, an optical filter, a receiver, a data acquisition and processing unit, a synchronization controller and a computer; the laser emitted by the laser source is shot on the optical path coupler, and the optical path coupler is connected to the scene by an optical fiber The distributed optical fiber is connected to the optical splitter by the wire at the same time. After the optical splitter, the optical filter, the receiver, and the data acquisition and processing unit are connected in series. The data acquisition and processing unit has input and output connections with the computer; the laser so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com