Resin-formed flexible puncture-proof fabric and preparation method thereof

A technology for resin molding and fabrics, which is applied in fiber types, textiles and papermaking, fiber processing, etc. It can solve problems such as uncomfortable wearing, unfavorable movement, complex processing, etc., and achieves short process flow, excellent bonding effect, and high-efficiency molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

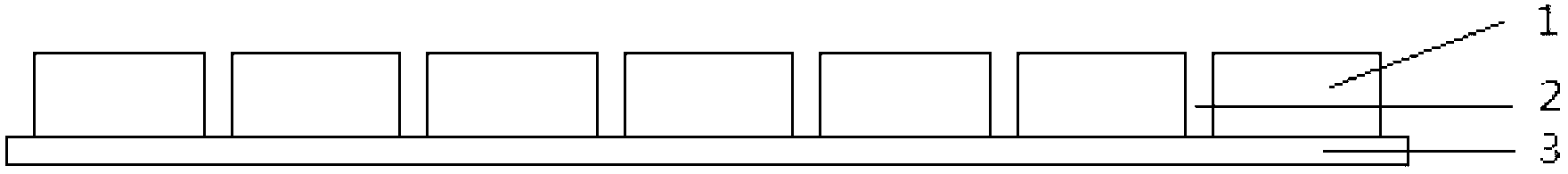

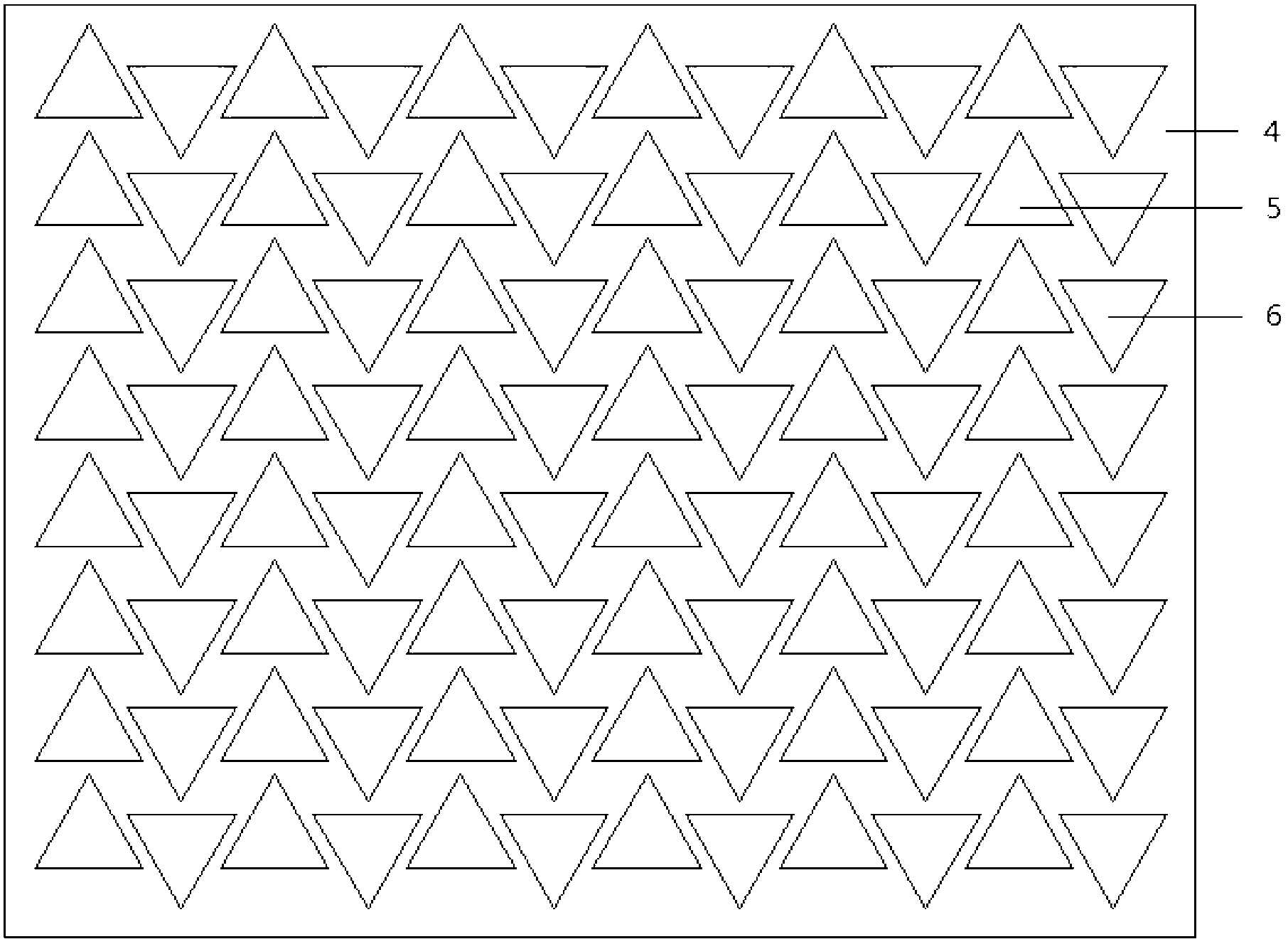

[0046] This flexible stab-resistant fabric uses nylon plain fabric as the base fabric, and the surface density is 180g / m 2 , the warp and weft density is 308×316 (root / 10cm). E44 epoxy resin and 650 polyamide resin curing agent, the mass ratio is 1:0.9, add 8% dioctyl phthalate toughening agent, 5% epoxy diluent (SM-90) and 5% resin mass % of color particles. The manufacturing process of this anti-stab fabric is as follows: a, at first epoxy resin is mixed with curing agent and auxiliary agent; b, this example adopts Figure 6 Honeycomb pattern screen, the side length of the hexagonal mesh in the screen is 4mm, the gap between the mesh and the mesh is 1mm, the height of the mesh is 1.0mm, and the resin mixture is evenly dispersed on each of the screen In the mesh, fill each mesh with resin, and then use a scraper to scrape off the excess resin on the surface of the mesh; c, spread the nylon fabric on the mesh filled with resin, and apply a surface of the same size and surfac...

Embodiment 2

[0050] This flexible anti-stab fabric uses polyester plain weave fabric as the base fabric, with a surface density of 210g / m 2 , the warp and weft density is 160×166 (root / 10cm). E44 epoxy resin and 650 polyamide resin curing agent, the mass ratio is 1:1, add 10% of resin mass dioctyl phthalate toughener, 5% epoxy diluent (SM-90) and 5 % of color particles. The manufacturing process of this anti-stab fabric is as follows: a, at first epoxy resin is mixed with curing agent and auxiliary agent; b, this example adopts Figure 5 The pentagons of the same size surround the square pattern of the screen, the side length of the pentagon mesh in the screen is 3mm, the side length of the square mesh is 5mm, the gap between the mesh and the mesh is 0.8mm, and the height of the mesh is 0.9 mm, the resin mixture is evenly dispersed in each mesh of the screen, so that each mesh is filled with resin, and then use a scraper to scrape off the excess resin on the surface of the screen; c, spr...

Embodiment 3

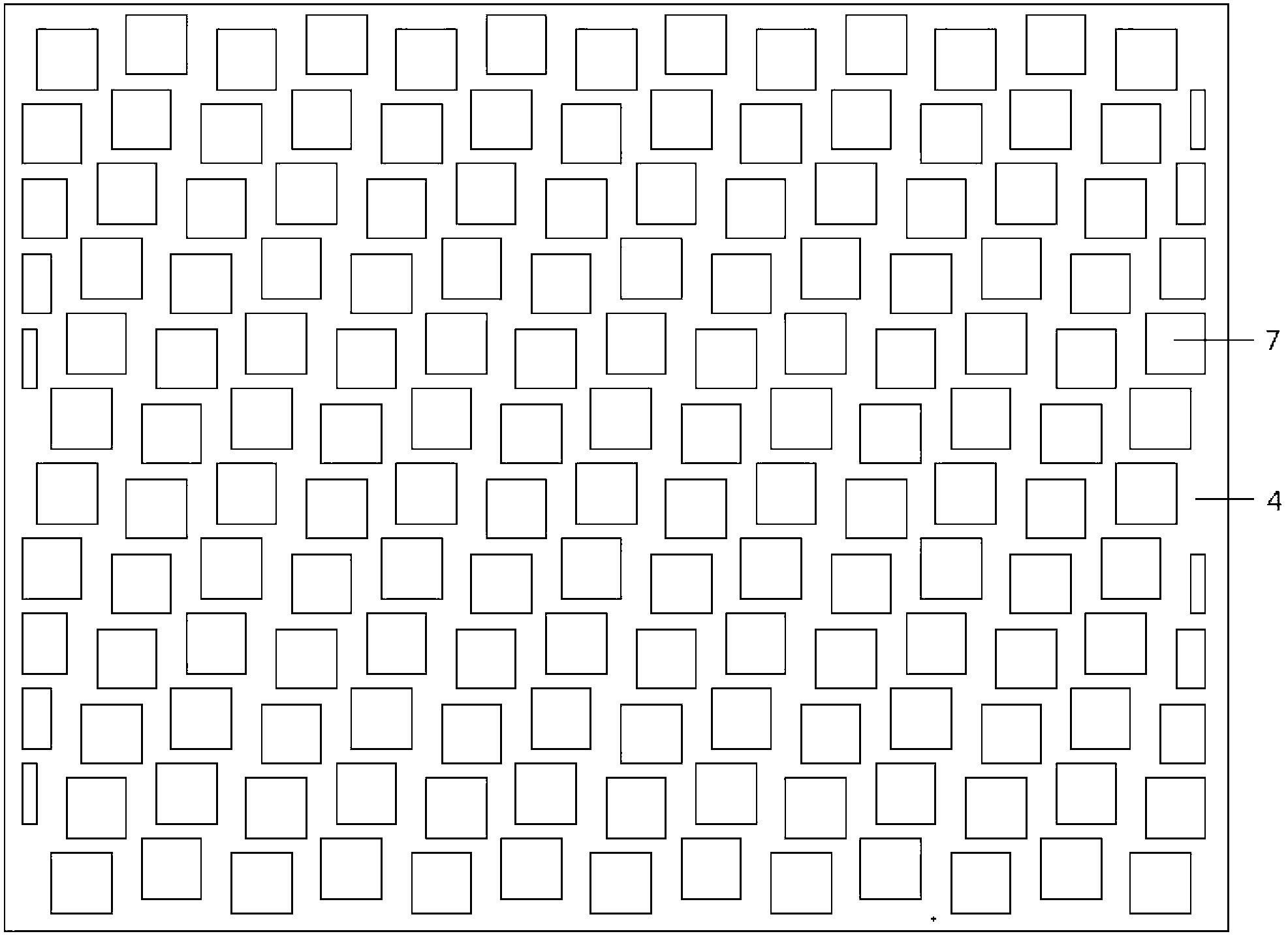

[0054] This flexible anti-stab fabric uses polyester plain weave fabric as the base fabric, with a surface density of 245g / m 2 , the warp and weft density is 280×298 (root / 10cm). Thermosetting acrylic resin (BS-965), isocyanate curing agent (740D), the mass ratio is 3:1, and 10% of the resin mass is added as a toughening agent of dibutyl benzene. The manufacturing process of this anti-stab fabric is as follows: a, at first this thermosetting acrylic resin is mixed with curing agent, auxiliary agent; B, this example adopts image 3 A mesh plate with the same size squares arranged in dislocation patterns, the side length of the square mesh in the mesh plate is 3mm, the gap between the mesh holes is 0.8mm, and the mesh height is 1.1mm. The resin mixture is evenly dispersed in the In each mesh hole of the screen, fill each mesh with resin, and then use a scraper to scrape off the excess resin on the surface of the screen; c, spread the polyester fabric on the screen filled with r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com