Method for recovering lead plaster of negative pole of disused lead acid storage battery and application of recovered lead plaster

A technology of lead-acid batteries and negative electrode paste, which is applied in the field of recycling and reuse of waste items, can solve the problems of difficult large-scale production, energy consumption, and high power consumption, and achieve the effects of reducing energy consumption, less pollution, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

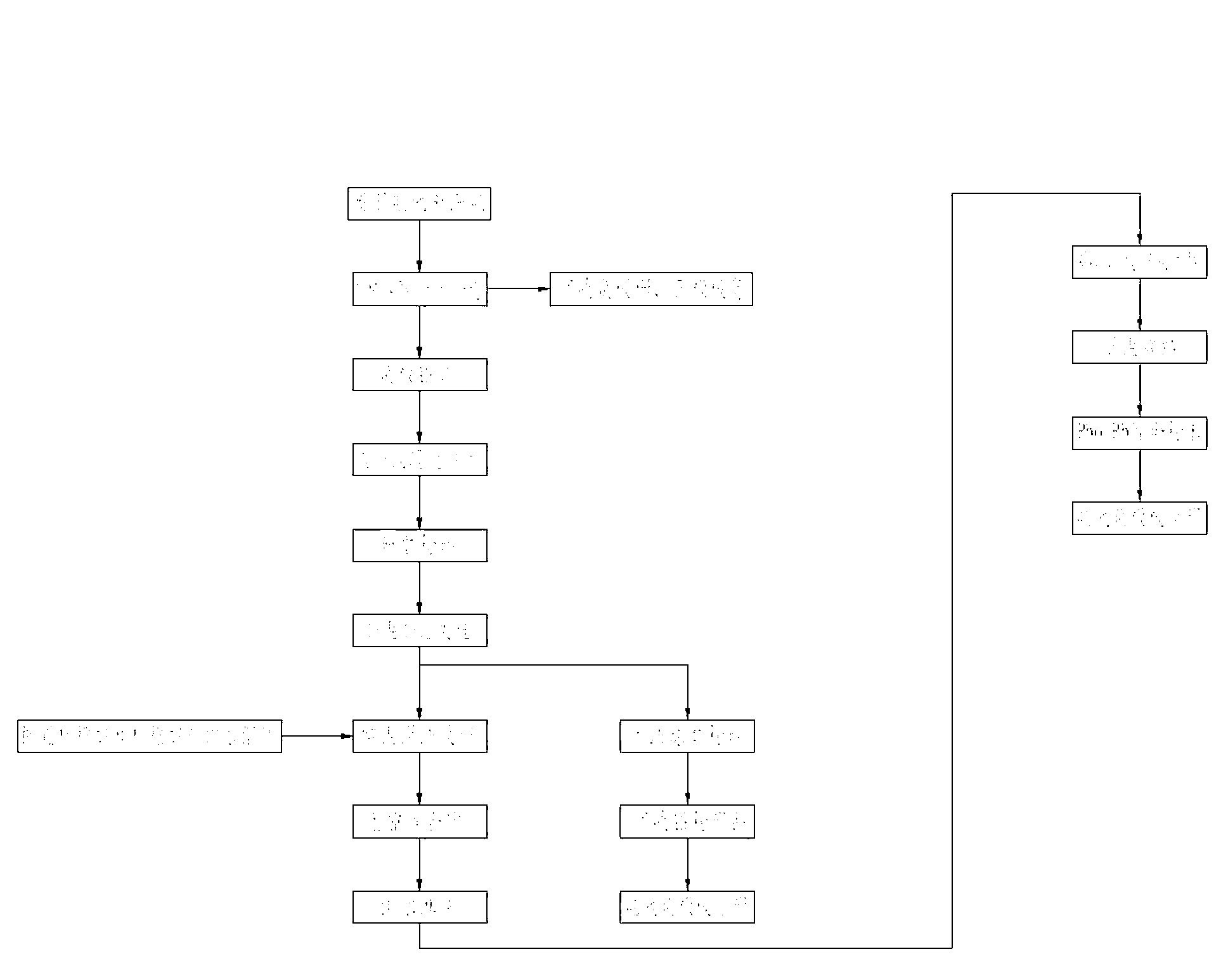

[0042] Further details will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0043] The present invention implements a method for reclaiming the negative lead paste of waste lead-acid batteries, comprising the following steps:

[0044] A. The waste lead-acid battery is fully charged, and the active material in the battery negative plate is converted into lead Pb; in a preferred embodiment of the present invention, the waste battery is fully charged at room temperature with 2.45V / battery unit Charge at a constant voltage of 0.2 coulombs for 4 to 10 hours with a current limit, and the battery unit refers to the smallest electrode unit that constitutes the lead-acid battery plate;

[0045] B. Use mechanical dismantling or crushing and sorting to separate and sort out the lead paste in the lead-acid battery treated in step A; the method of mechanical dismantling refers to the method of rotating and colliding the battery plates to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com