Secondary fermentation tunnel device for agaricus bisporus compost

A technology for secondary fermentation and culturing material, which is applied in fertilization devices, organic fertilizers, preparation of organic fertilizers, etc., to save energy and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

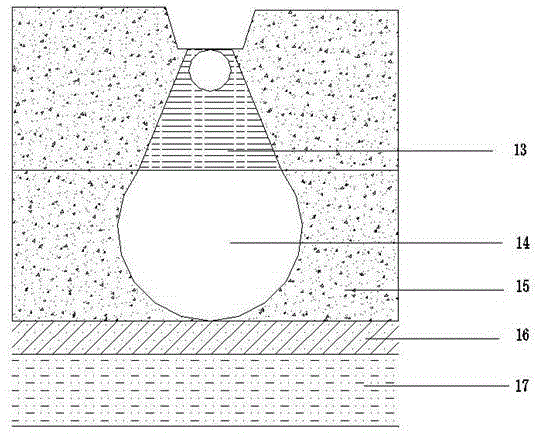

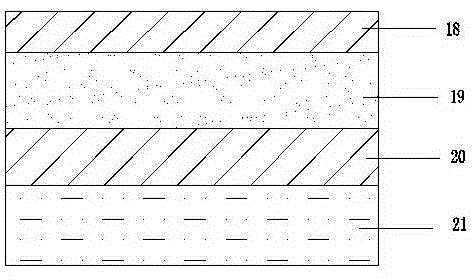

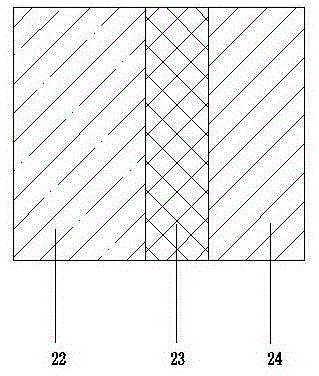

[0022] A secondary fermentation tunnel device for Agaricus bisporus compost consists of a closed tunnel body consisting of a fermentation tunnel top (1), a tunnel wall, and a high-pressure jet floor (12); the fermentation tunnel top (1) is composed of a waterproof layer (18), a slag pad layer (19), benzene board insulation layer (20) and concrete layer (21) in sequence; the tunnel wall consists of tunnel back wall (4) and side wall (11), and 11) are composed of concrete pouring layer (22), benzene board insulation layer (23) and brickwork layer (24) in sequence, and the back wall (4) of the tunnel is provided with a return air outlet (5) and an air inlet (9). Ventilation and exhaust pipe system; the high-pressure air jet ground (12) is composed of a concrete layer (15), an insulation layer (16) and a slag cushion (17) in sequence, and the high-pressure air nozzle (13) and The ventilation pipe (14) consists of a piping system for the high-speed circulation of hot air.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com