Visual preparation method of polymeric fibers based on laser scanning confocal microscope

A polymer fiber, laser confocal technology, applied in the field of laser confocal microscope imaging, can solve problems such as inability to observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

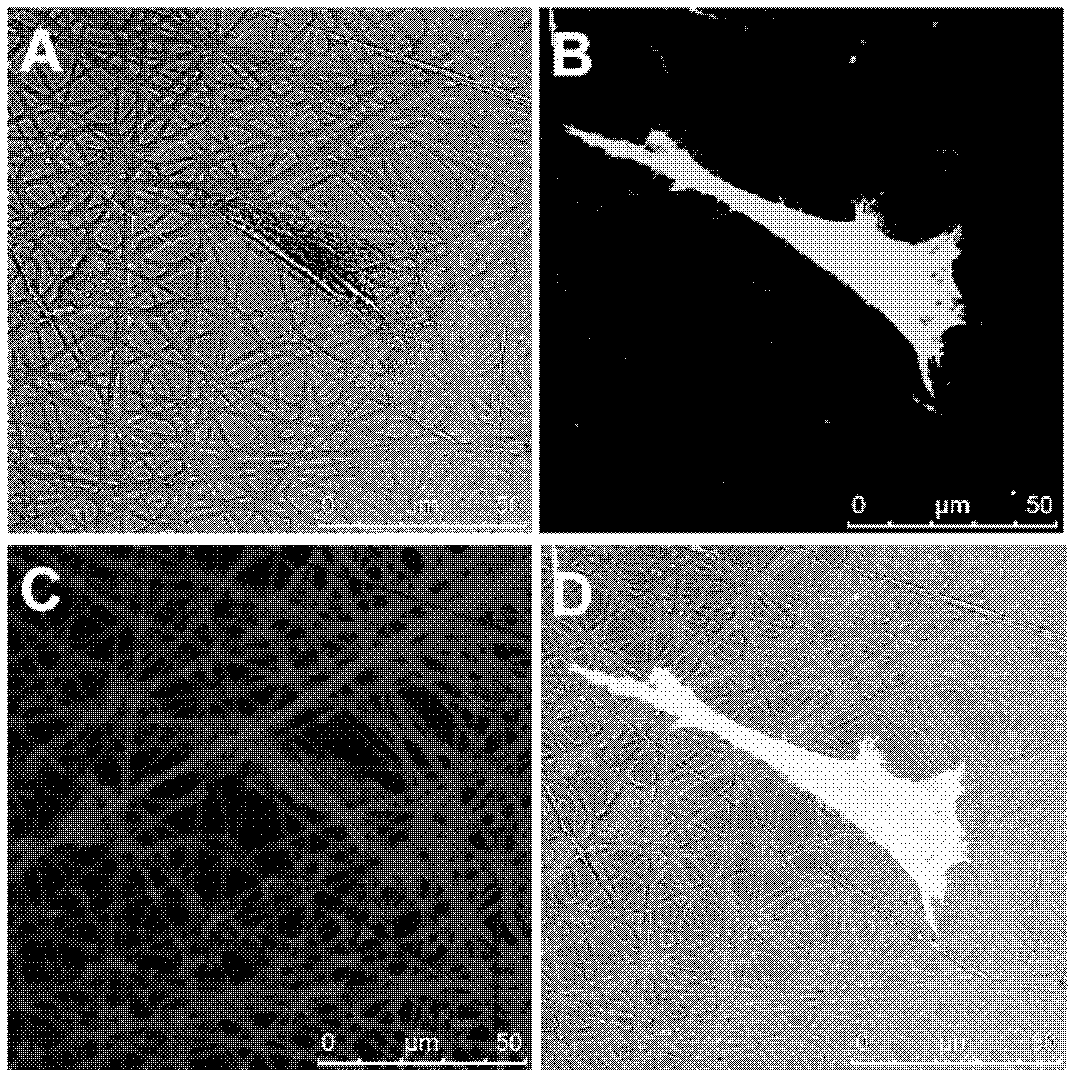

Image

Examples

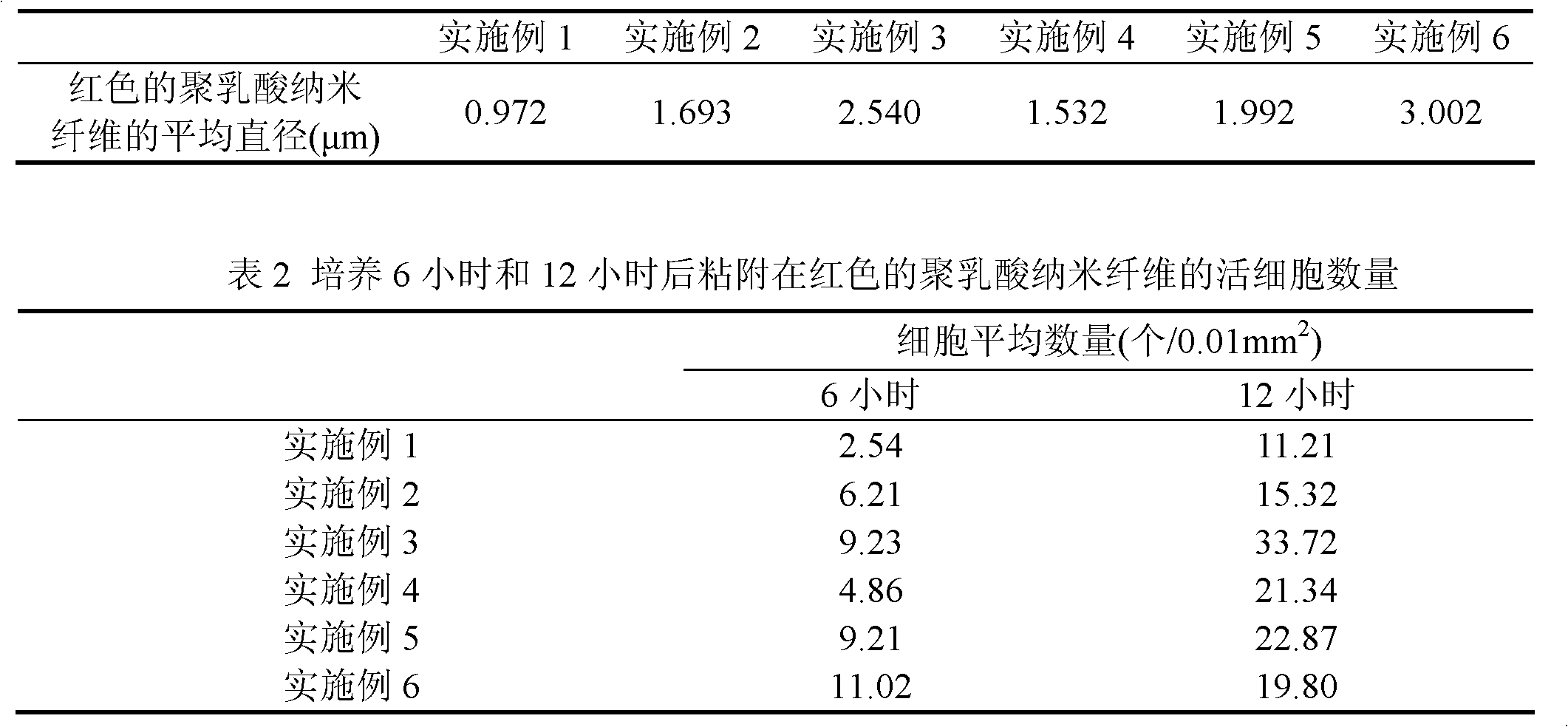

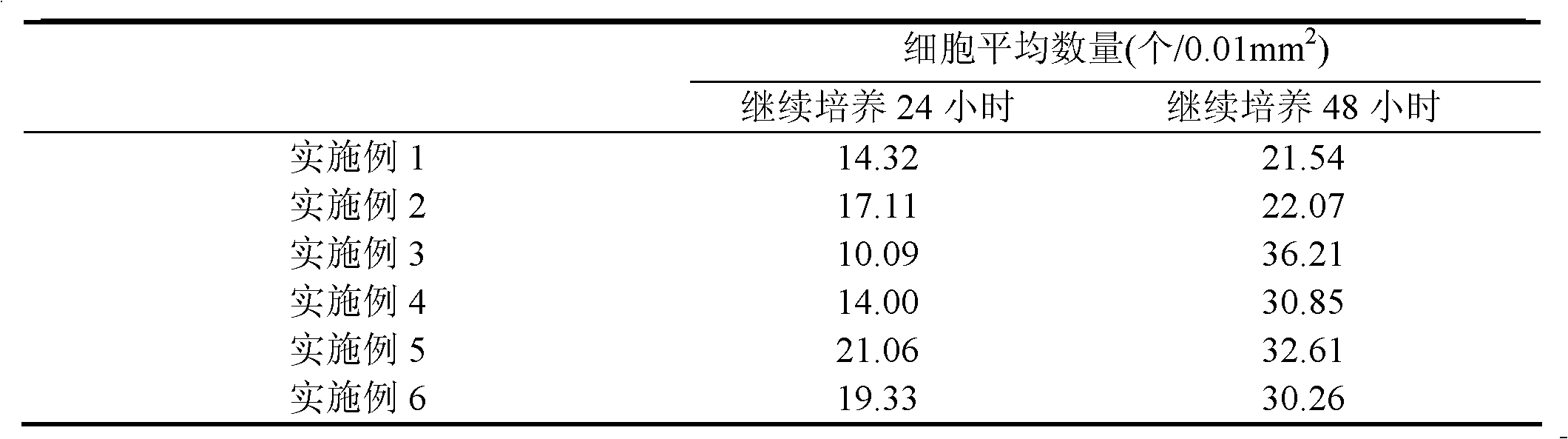

Embodiment 1

[0036] Weigh 0.2g of polylactic acid, put it into 20ml of dichloromethane solvent, heat and condense to reflux and dissolve for 1 hour until the copolymer is completely dissolved and the solution is colorless and transparent. Add 10 mg of red dye isothiocyanerhodamine B to the above solution, stir and dissolve until it becomes a red transparent liquid. Put it into the glass syringe in the spray device so that the injection rate is 0.3ml / hour, a high voltage of 10,000 volts is generated between the positive electrode of the needle tip and the negative electrode of the substrate, and the distance between the needle tip and the receiving device is 30mm, and a glass piece is used to collect the The polylactic acid fibers coated with isothiocyanerhodamine B ejected by electrospinning were collected for 15 minutes. Soak the polylactic acid nanofibers coated with isothiocyanato-rhodamine B in 200ml of pure water, and shake on a constant temperature shaker at room temperature for 3 da...

Embodiment 2

[0040] Weigh 1g of polylactic acid, put it into a mixed solvent of 18ml of dichloromethane and 2ml of N,N-dimethylformamide, heat and condense to reflux for 1 hour until the copolymer is completely dissolved and the solution is colorless and transparent. Add 20 mg of red dye isothiocyanerhodamine B to the above solution, stir and dissolve until it becomes a red transparent liquid. Put it into the glass syringe in the spraying device so that the injection rate is 0.3ml / hour, a high voltage of 5000 volts is generated between the positive electrode of the needle tip and the negative electrode of the substrate, and the distance between the needle tip and the receiving device is 20 mm, and the passing through is collected with a glass sheet. The polylactic acid fibers coated with isothiocyanerhodamine B ejected by electrospinning were collected for 120 minutes. Soak the polylactic acid nanofibers coated with isothiocyanato-rhodamine B in 400ml of pure water, and shake on a constant...

Embodiment 3

[0044] Weigh 1g of polylactic acid and 1g of polycaprolactone, put them into 20ml of dichloromethane solvent, heat and condense to reflux for 1 hour until the copolymer is completely dissolved and the solution is colorless and transparent. Add 100 mg of red dye isothiocyanerhodamine B to the above solution, stir and dissolve until it becomes a red transparent liquid. Put it into the glass syringe in the spraying device so that the injection rate is 0.1ml / hour, a high voltage of 5000 volts is generated between the positive electrode of the needle tip and the negative electrode of the substrate, and the distance between the needle tip and the receiving device is 15mm, and a glass piece is used to collect the The polylactic acid fibers coated with isothiocyanerhodamine B ejected by electrospinning were collected for 30 minutes. Soak the polylactic acid nanofibers coated with isothiocyanato-rhodamine B in 200ml of pure water, and shake on a constant temperature shaker at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com