Preparation method of nano bamboo fiber composite material

A technology of nano-bamboo fiber and composite material, which is applied in the direction of artificial filament in cellulose solution, fiber treatment, fiber chemical characteristics, etc., to achieve the effect of saving energy and cost, large specific surface area, and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

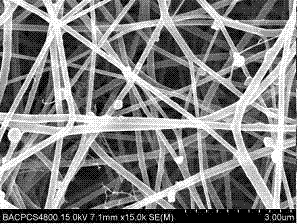

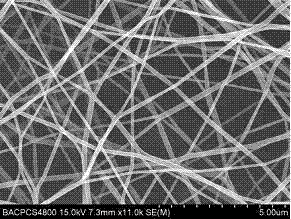

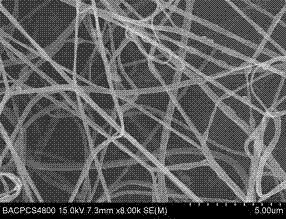

Image

Examples

Embodiment 1

[0028] The bamboo pulp is activated by the methanol / DMAc replacement method, soaking the bamboo pulp in distilled water overnight to make it fully swell, washing the swollen bamboo pulp three times with methanol, soaking for 45 minutes, and filtering after soaking. They were washed three times with DMAc, soaked for 45 minutes, filtered, and then dried in a 110°C electric constant temperature blast drying oven. Use 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc solvent system to dissolve the activated bamboo pulp, add the dried LiCl to the DMAc at 40 ° C, stir until the LiCl is completely dissolved, Prepare 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc mixed solvent. Add the dried bamboo pulp into 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc solvent system according to the proportion, stir at 80°C for 12h, take it out and continue stirring at room temperature until bamboo The pulp is completely dissolved to make 4% bamboo pulp. DMAc was used to dissolve PAN to prepare a 16% P...

Embodiment 2

[0030] The bamboo pulp cake is activated by a heating activation method, soaking the bamboo pulp cake in distilled water overnight to make it fully swell, and drying the swollen bamboo pulp cake for use. Weigh 4 g of cellulose raw material into a conical flask, add 100 mL of DMAc, heat to 150 °C, stir at this temperature for 20-30 min, continue stirring for 2 h under reflux, then cool down to 100 °C, add 0.8 g of dry LiCl was stirred at this temperature for 2 h, cooled to room temperature and placed until the bamboo cellulose was dissolved. DMAc was used to dissolve PAN to prepare a 16% PAN solution, and the bamboo slurry and polymer solution were mixed in a certain proportion to prepare a spinning solution with a bamboo cellulose content of 8%. Using the electrospinning device, put the bamboo pulp spinning solution into the needle tube, connect the positive and negative poles, turn on the high-voltage DC generator power supply, and spin under the conditions of spinning voltag...

Embodiment 3

[0032]The bamboo pulp is activated by the methanol / DMAc replacement method, soaking the bamboo pulp in distilled water overnight to make it fully swell, washing the swollen bamboo pulp three times with methanol, soaking for 45 minutes, and filtering after soaking. They were washed three times with DMAc, soaked for 45 minutes, filtered, and then dried in a 110°C electric constant temperature blast drying oven. Use 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc solvent system to dissolve the activated bamboo pulp, add the dried LiCl to the DMAc at 40 ° C, stir until the LiCl is completely dissolved, Prepare 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc mixed solvent. Add the dried bamboo pulp into 8% (w / v, w unit is Kg, v unit is L) LiCl / DMAc solvent system according to the proportion, stir at 80°C for 12h, take it out and continue stirring at room temperature until bamboo The pulp is completely dissolved to make 4% bamboo pulp. DMAc was used to dissolve PS-PAN copolymer to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com