Lithium zirconate ceramic ball tritium breeding material and preparation method thereof

A technology of zirconia ceramic balls and ceramic balls, applied in the field of nuclear energy, can solve the problems of waste and high breakage rate, and achieve the effect of good density and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

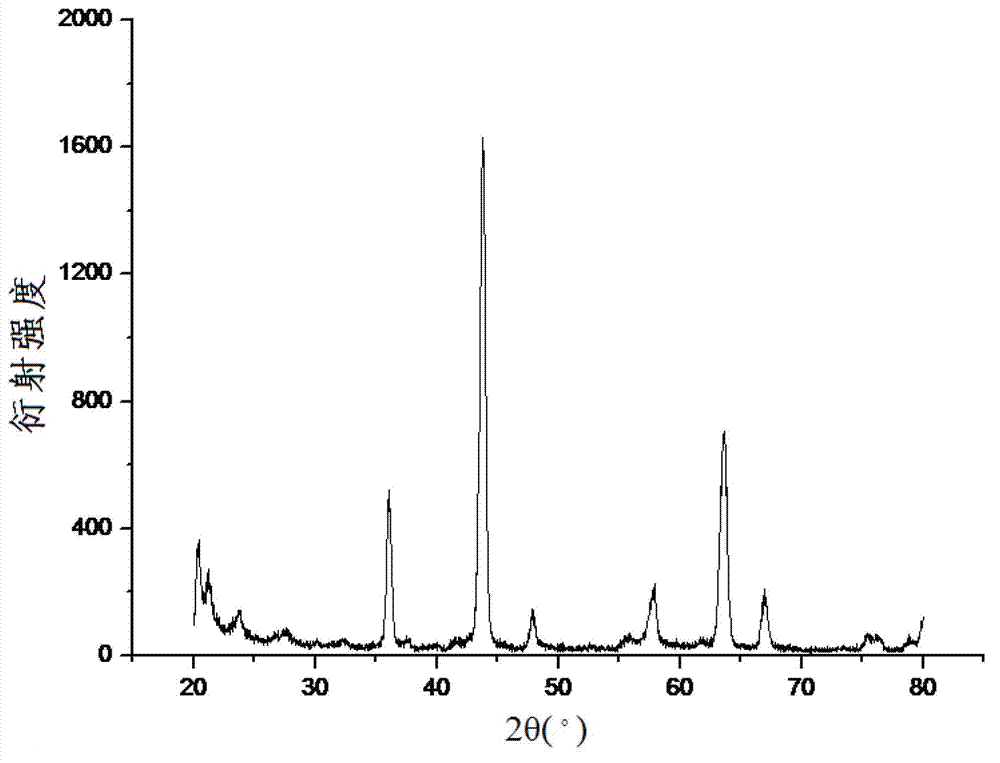

Image

Examples

Embodiment 1

[0023] (1) Mix 0.11 mol of lithium carbonate, 0.1 mol of zirconia, and 100 ml of ethanol; use zirconia ceramic balls as grinding balls for the mixed solution, and mix on a ball mill for 4 hours. Dry in an oven for 4 hours at 80°C.

[0024] (2) Sinter the mixture in the sintering furnace. Raise the temperature to 600°C in two hours, keep the temperature for 3 hours, then raise the temperature to 900°C in two hours, and keep the temperature for 24 hours. Then cool naturally. After taking it out, use zirconia ceramic balls to grind powder on a ball mill, grind for 4 hours, and sieve.

[0025] (3) Put the ceramic powder into the rubber mold, and pressurize the rubber mold on the isostatic press with a pressure of 150 MPa.

[0026] (4) Sinter the isostatically pressed ceramic balls in a high-temperature furnace at a temperature of 1200-1350 °C and a holding time of 5-8 hours. After heat preservation, the material is cooled with the furnace, and after cooling to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com